Tag#for Pipe Bend Get: 31 results / Total 3 pages

Pipe bends are curved piping components used to change the direction of fluid flow in pipelines, offering smooth transitions and reduced pressure drop for various industrial applications.

Heavy-duty steel bends with seamless cast basalt lining for maximum wear and corrosion resistance in industrial fluid systems. cast basalt lined bends provide exceptional abrasion and corrosion protection with smooth basalt lining—ideal for industrial pipeline direction changes under harsh conditions.

A 7d pipe bending is a pipe bend that the bend radius is 7 times the pipe outside diameter.

Steel bend pipe with ceramic lining for superior abrasion, corrosion, and thermal protection in challenging industrial flow curves.

Astm a210 grade c pipe bending involves forming seamless medium-carbon steel tubes into bends (e.g., 3d, 5d, 7d, or 180° u-bends) for high-pressure boiler applications.

15crmog pipe bending involves shaping seamless alloy steel pipes into bends (e.g., 3d, 5d, 7d, or 180° u-bends) for high-pressure, high-temperature applications. 15crmog, a chromium-molybdenum heat-resistant steel, contains approximately 0.15% carbon, chromium, and molybdenum, offering exceptional high-temperature strength (up to 550°c), oxidation resistance, and corrosion resistance.

12cr1movg pipe bending refers to the process of shaping 12cr1movg steel pipe into a curved form, often necessary for high-temperature and high-pressure applications like boiler tubes. 12cr1movg is a heat-resistant low-alloy steel containing chromium, molybdenum, and vanadium, which provides excellent strength and corrosion resistance at elevated temperatures.

Rare earth alloy wear resistant pipe bending provides robust, long-lasting pipe bends that withstand extreme abrasion and impact, ideal for demanding slurry and powder conveying pipelines.

Bending astm a213 t91 requires special care and techniques due to its high tensile strength and chromium-molybdenum alloy composition, which enhances its high-temperature performance and corrosion resistance but also makes it more prone to cracking if not handled properly.

Large size pipe bending refers to the technique of bending pipes with large diameters, often over 24 inches (600 mm). due to the pipe’s size and weight, specialized equipment and expertise are needed to achieve precise bends while preserving the pipe’s structural integrity.

5d pipe bending solutions, crafted from carbon and stainless steel, designed for corrosion-resistant industrial piping in oil and gas, power generation, and automotive applications with superior flow efficiency.

3d pipe bends are pipe fittings with a bend radius three times the pipe’s nominal diameter, designed for industrial piping systems requiring smooth flow and high efficiency.

Bimetal clad pipe is cast with mold vanishing vacuum suction casting cladding process.

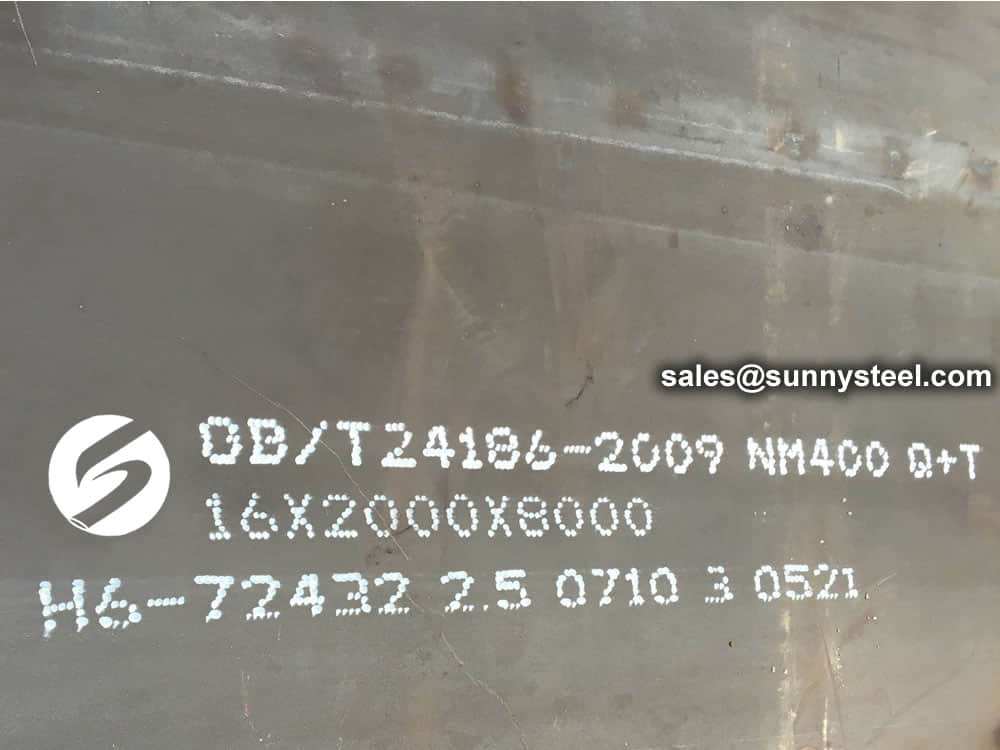

NM400 Steel Plate is a type of wear-resistant steel plate that is commonly used in various industrial applications.

Ceramic tile lined pipes are pipelines that have a ceramic tiles lining layer inside a steel pipe.

The wear resistance of the pulverized coal conveying pipeline of the boiler of the thermal power plant must be designed for leakproof, anti-corrosion, rain-proof, anti-freeze and other factors.