Wear & Corrosion Relief

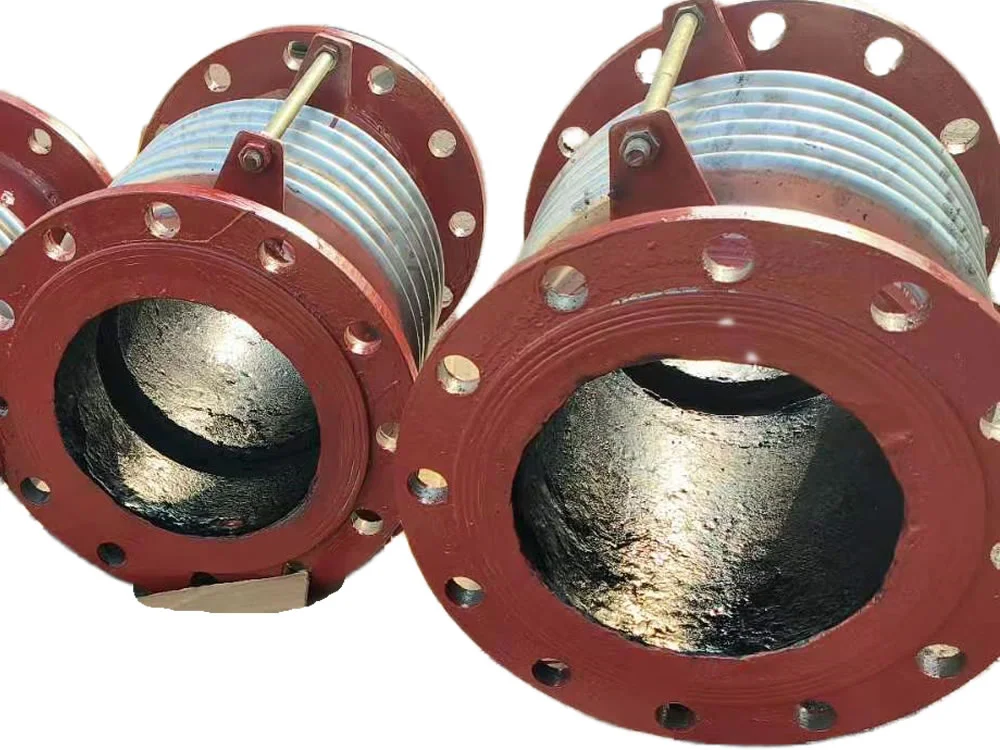

Ceramic-lined pipe expansion joints combine movement flexibility with high corrosion and wear resistance—designed for slurry, ash, chemical, and heat-cycled pipeline systems.

Wear & Corrosion Relief

Ceramic-lined pipe expansion joints combine movement flexibility with high corrosion and wear resistance—designed for slurry, ash, chemical, and heat-cycled pipeline systems.

Ceramic-lined pipe expansion joints are engineered connectors that accommodate pipeline movements (due to thermal expansion, vibration, or misalignment) while providing robust protection against abrasion, corrosion, and temperature stress. Each joint consists of an inner ceramic-lined sleeve (typically alumina or silicon carbide), a flexible steel bellows or sleeve, and end connectors for seamless integration.

Ceramic-lined pipe expansion joints are specialized components designed to absorb dimensional changes in piping systems due to thermal expansion and contraction, while also providing wear and corrosion resistance. These joints typically feature an outer metal shell, an inner layer of wear-resistant ceramic, and connecting parts. They are crucial for high-temperature applications like steam or exhaust gas lines, where thermal expansion is significant.

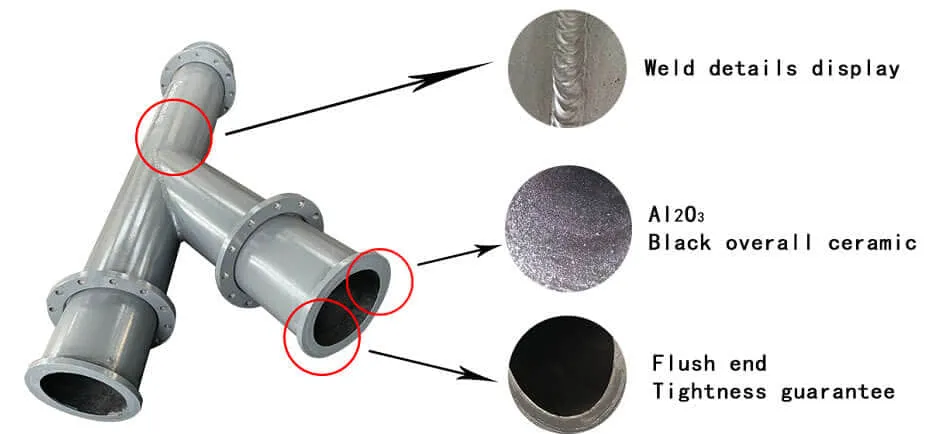

Inner liner ceramic wear-resistant steel pipe is made by SHS high-temperature synthesis-centrifugal method. The melting point of corundum in ceramic steel pipe is 2045°C.

When temperature rises to 900°C and the pipe is repeatedly soaked in water, the composite layer does not crack, showing incomparable thermal shock resistance compared to ordinary ceramics. This performance is invaluable in construction applications.

| Items | Index |

|---|---|

| Alumina Content | 92% |

| Bulk Density | 3.62g/cm³ |

| Rockwell Hardness (HRA) | 90 |

| Compressive Strength | 850MPa |

| Fracture Toughness | 4.8MPa·M¹/² |

| Bending Strength | 290MPa |

| Thermal Conductivity at 20℃ | 20W/m·K |

| Coefficient of Thermal Expansion | 7.2×10⁻⁶m/(m·K) |

| Young's Modulus at 20℃ | 277GPa |

| Shear Modulus at 20℃ | 113GPa |

| Surface Finish (As-Fired) | 1.27mm |

Wear-resisting bend (wear-resistant ceramic pipe), as the name implies, is a relatively traditional yet more abrasion-resistant pipe. Manufactured with new wear-resistant plastics, it is widely used in large-scale industries and currently holds approximately 80% of the market share.

| Sand Injection Test | 30% SiO₂ Sludge Transfer Test | ||

|---|---|---|---|

| Material | Volume Diminution (cm³) | Material | Volume Diminution (cm³) |

| Ceramic Lined Steel Pipe | 0.0022 | Ceramic Lined Steel Pipe | 3 |

| Ceramic Pipe (Al₂O₃ 97%) | 0.0025 | S45C Steel | 25 |

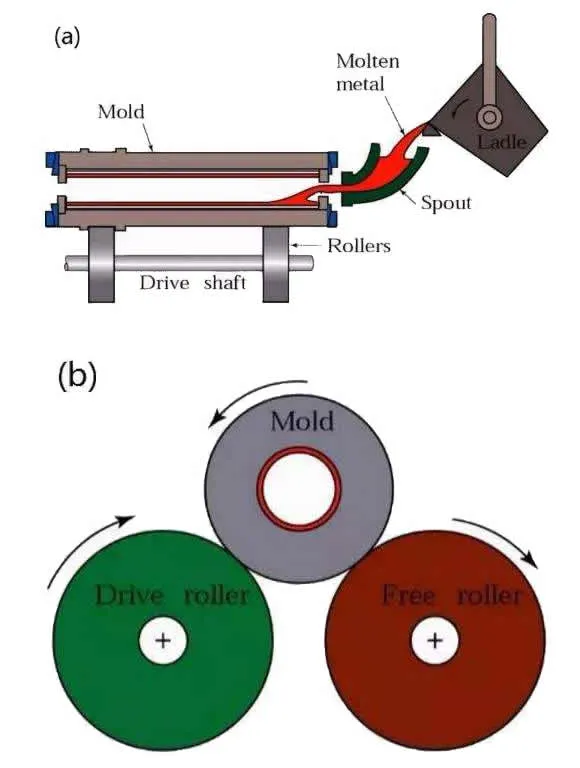

The SHS (Self-Propagating High-Temperature Synthesis) technology is part of China’s national "863" high-tech project, producing composite pipes with exceptional performance in harsh industrial environments.

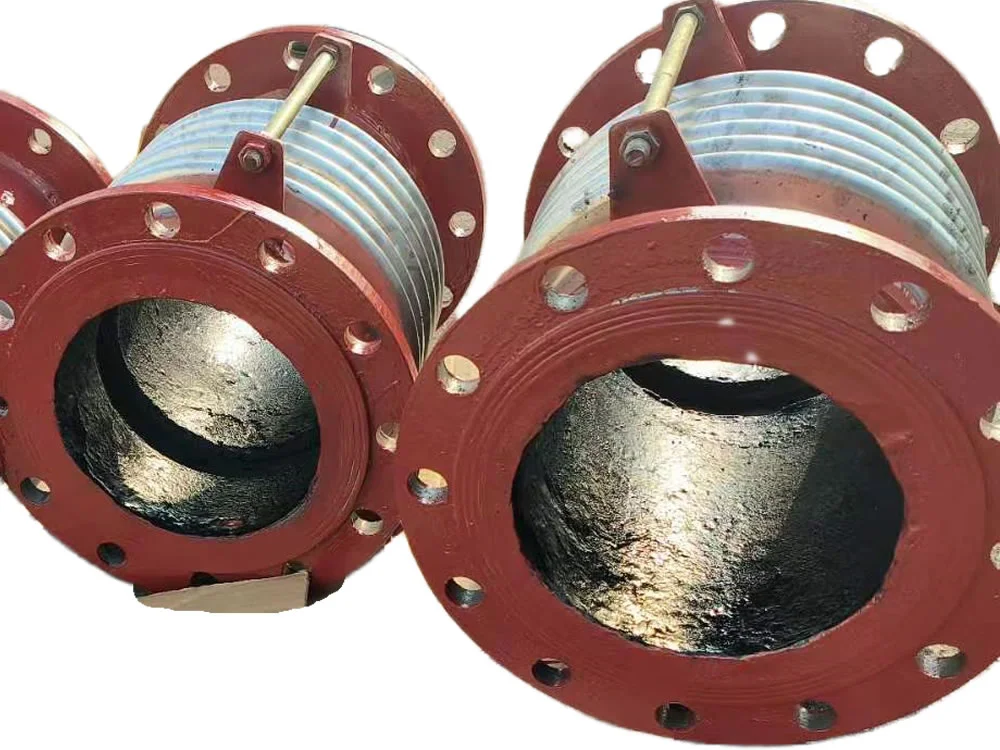

Self-propagating high temperature synthesis (SHS) is used to describe a process in which the initial reagents (usually powders), when ignited, spontaneously transform into products due to the exothermitic heat of reaction.

A well-known example of SHS reaction is the thermite reaction given below:

This reaction generates temperatures above the melting point of alumina and is used in the thermit welding process for joining railway lines.

Several other terminologies - such as combustion synthesis, gasless combustion or self-propagating exothermic reaction - are used to describe the process.

The types of material that can be formed using this process include metal borides, silicides, carbides, nitrides, sulphides, aluminides and oxides.

The ceramic layer achieves Mohs hardness of 9.0 (HRC ≥90), which is nearly as hard as diamond. This makes it ideal for transporting abrasive materials in mining, metallurgy, coal, and power industries, outperforming traditional steel pipes by 5-10 times in wear resistance.

Ceramic steel pipe and traditional steel pipe, wear-resistant alloy cast steel pipe, cast stone pipe, as well as steel plastic, steel rubber pipe, etc. have essential differences. The outer layer of ceramic steel pipe is steel, and the inner is corundum. The Vickers hardness of corundum layer is as high as 100-1500 (Rockwell hardness is 90-98), which is equivalent to tungsten cobalt hard gold. The wear resistance is more than 20 times times higher than carbon steel pipe, it is superior to the corundum grinding wheel which is usually bonded. Now the corundum grinding wheel is still the main grinding wheel of the grinding mill. The corundum layer in the ceramic steel tube can wear away the corundum grinding wheel. The abrasion resistance of ceramic steel tube is mainly by the inner layer of several millimeters thick corundum layer, its Morse hardness is 9, second only to diamond and SIC, in all oxides, its hardness is the highest.

The inner liner ceramic wear-resisting steel pipe is made by SHS high temperature synthesis-centrifugal method, the melting point of corundum in ceramic steel pipe is 2045 ℃, the corundum layer and steel layer have special structure and stress field because of the process reason. Under normal temperature, the compressive stress of the ceramic layer, the tensile stress of the steel layer, the two opposites, into a balanced whole. Only when the temperature rises to more than 400 ℃, because the thermal expansion coefficient is different, the new stress field produced by the thermal expansion and the original stress field in the ceramic steel pipe cancel each other, so that both the ceramic layer and the steel layer are in a free equilibrium state. When the temperature rises to 900 ℃ the inner liner ceramic wear-resistant steel pipe into the water, repeatedly soaked repeatedly, the composite layer does not crack or cracking, showing the incomparable thermal shock resistance of ordinary ceramics. This performance is of great use in construction, because the outer layer is steel, in addition to heating the inner layer does not crack, in the construction, the flange, blowing, explosion-proof doors can be welded, but also can be directly welded to connect, which is more than wear-resistant cast stone pipe, wear-resistant cast steel pipe, Rare-earth wear-resistant steel pipe, bimetal composite pipe, steel pipe, Steel rubber pipe In the construction is not easy to weld or welding more than a chip. Internal liner ceramic Wear-resistant steel pipe resistance to mechanical impact is good, in transport, installation beat and the two support between the weight bending deformation, the composite layer does not break off.

At present, the practice of dozens of thermal power plants shows that the wear resistance of the inner-lined ceramic steel tube is high, and the resistance to fluid scouring is strong. In the first air duct, the bending pipe wear the most quickly, the wear resistance of the inner liner ceramic wear-resisting steel pipe is more than 5 times times higher than that of the thick wall wear-resisting cast steel elbow.

In practice, the inner liner ceramic wear-resistant steel pipe after 1-2 years to open observation and measurement, the composite layer has no obvious wear or fall off, in the same size and unit length of the pipeline, the internal liner ceramic wear-resistant steel tube weight only wear-resistant cast steel pipe or bimetal composite pipe of about 1/2, the cost of each of the meters reduced 30–40%, Only cast stone pipe and Rare-earth wear-resistant steel pipe weight of about 2/5, per meter project cost reduction of more than 20%. In the corrosive or high-temperature place to use the liner ceramic wear-resistant steel pipe, its price is only a stainless steel tube, nickel-titanium tube of a fraction of.

Fluid pipeline transportation is not only used in the power industry, but also in metallurgy, coal, petroleum, chemical, building materials, machinery and other industries. When the pipe is transported with large grinding material (such as ash residue, pulverized coal, mineral fine powder, tailings cement, etc., there is a problem of fast abrasion of pipe, especially the bending pipe wear fast; when conveying a strong corrosive gas, liquid or solid in the pipeline, there is a problem that the pipeline is corroded and destroyed quickly. When conveying the material with high temperature in the pipeline, there are some problems such as the price of heat-resisting steel pipe is very expensive. The internal liner ceramic wear-resistant steel pipe market, these problems are solved.

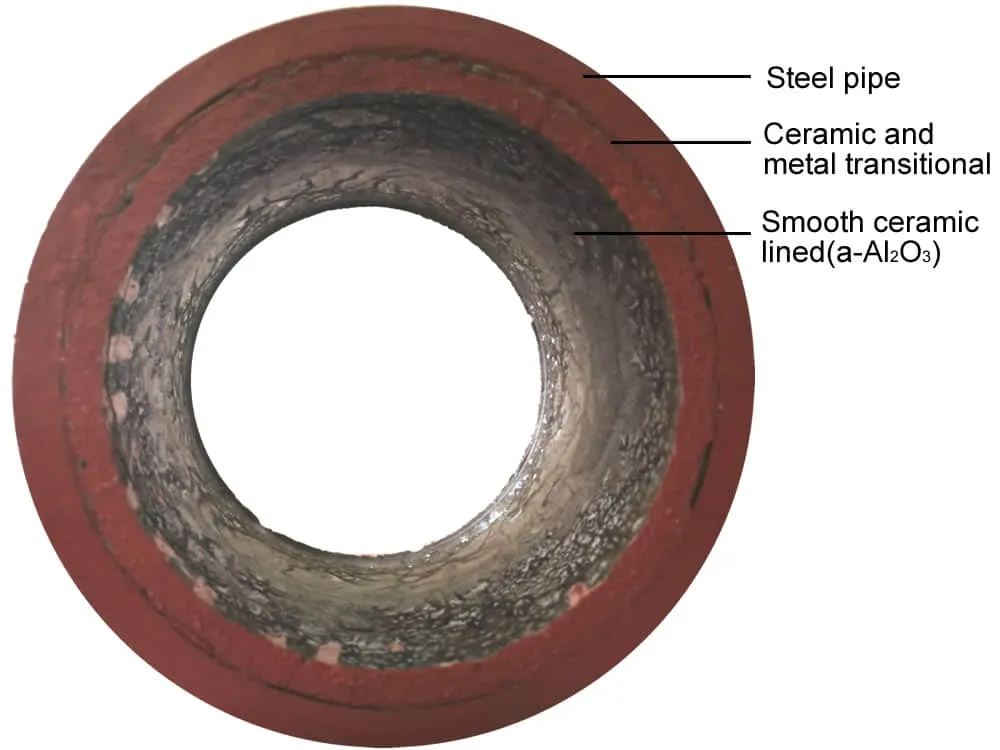

Steel pipe → Ceramic and metal transitional → Smooth ceramic lined (α-Al₂O₃)

Steel pipe → Ceramic and metal transitional → Smooth ceramic lined (α-Al₂O₃)

Ceramic lined pipe is a specialized pipeline system featuring an inner ceramic lining that provides superior resistance to wear, abrasion, and corrosion. The ceramic lining is typically made of high-quality corundum ceramic (α-Al₂O₃) material.

Self-propagating High-temperature Synthesis technology of corundum ceramic composite steel pipe utilizes "SHS" technology composite, a national High-tech "863" project originally promoted by the national metallurgical Industry Department and Ministry of Electricity.

The tube consists of three parts from inside to outside: ceramic (corundum) layer, transition layer, and steel layer, creating a durable composite structure.

Corundum ceramic (α-Al₂O₃) with Mohs hardness of 9.0, equivalent to HRC90+. Wear life is 10-20 times longer than hardened steel, confirmed by industrial operation.

Smooth inner surface with drag coefficient of 0.0193, better than any metal pipe. Reduces operating costs and improves flow efficiency.

Neutral α-Al₂O₃ ceramic layer resists acid, alkali, and seawater corrosion while preventing scale buildup.

Operates normally in temperature range of -50°C to 700°C. Linear expansion coefficient of 6-8 × 10⁻⁶/°C, about 1/2 of steel pipe.

50% lighter than cast stone pipes, 20-30% lighter than wear-resistant alloy pipes. Project cost reduced by about 20% compared to wear-resistant alloy pipes.

Lightweight design with excellent welding performance. Supports welding, flanges, quick coupling methods for convenient installation.

There are hundreds of different methods for packing abrasion-resistant pipes and elbows, each with unique merits. However, two principles are vital for any effective method: rust prevention and maritime transportation security.

Fluid pipeline transportation solutions for multiple industries including power, metallurgy, coal, petroleum, chemical, building materials, and machinery.

Ash handling, coal transport, flue gas systems, pulverized coal transport

Ore transport, tailings handling, slurry systems, mineral fine powder transport

High-temperature material transport, furnace systems, heat-resistant applications

Corrosive media transport, process piping, building materials handling

When transporting large grinding materials like ash residue, pulverized coal, mineral fine powder, and tailings cement.

When conveying strong corrosive gas, liquid, or solid materials that quickly corrode and destroy pipelines.

Cost-effective alternative to expensive heat-resistant steel pipes for high-temperature material transport.

Ceramic-Lined Steel Composite Pipe

Sort:0

Metal Ceramic Lined Composite Pipe

Sort:0

Ceramic‑Lined Steel Composite Pipe

Sort:0

Ceramic-Lined Composite Steel Pipe

Sort:0

Wear‑Resistant Ceramic‑Lined Pipe

Sort:0

Abrasion-Resistant Alumina Ceramic Lining Bend

Sort:0

Ceramic-Lined Low Carbon Steel Pipe

Sort:0

Alumina Ceramic-Lined Elbow and Pipe

Sort:0