Long-life Solution For Extreme Abrasive Flow

Rare earth wear resistant pipes deliver outstanding durability and protection against abrasion, ideal for high-wear applications in mining, power, and material handling industries.

Long-life Solution For Extreme Abrasive Flow

Rare earth wear resistant pipes deliver outstanding durability and protection against abrasion, ideal for high-wear applications in mining, power, and material handling industries.

Rare Earth Alloy Wear Resistant Pipes are advanced industrial piping solutions made from high-strength rare earth alloy castings. These pipes are engineered to deliver exceptional resistance to abrasion, corrosion, and high temperatures.

Thanks to their superior durability, they are widely used in harsh environments such as:

Rare Earth Alloy Pipes significantly extend service life and reduce downtime, making them a cost-effective choice for abrasive material transport.

Ceramic-lined pipes are known for their high hardness, wear resistance, thermal stability, and self-lubricating performance. Made from rare earth alloy steel and high-purity alumina ceramics, they offer superior performance in abrasive and high-temperature environments.

Ceramic-lined pipes are reinforced with anti-shedding alumina tiles, strong inorganic adhesives, and precision welding. This dual-layer structure ensures long-term performance under high-stress, corrosive, and abrasive conditions.

These pipes are designed for flexible installation, low maintenance, and cost-effectiveness, making them ideal for use in mining, thermal power plants, steelworks, and chemical industries.

Rockwell hardness of alumina ceramics reaches HRA80–90, second only to diamond and much higher than wear-resistant steel.

Alumina ceramics provide 266× the wear life of manganese steel and over 170× that of high chromium cast iron.

Withstands continuous service temperatures up to 1400°C, making it suitable for furnaces and kilns.

Smooth surface reduces flow resistance; surface roughness is 1/6 that of steel pipes.

Supports thick-walled, curved, and shaped designs to match various piping systems and wear zones.

With a density of ~3.6g/cm³, alumina ceramic pipes weigh half as much as steel, improving transport and installation efficiency.

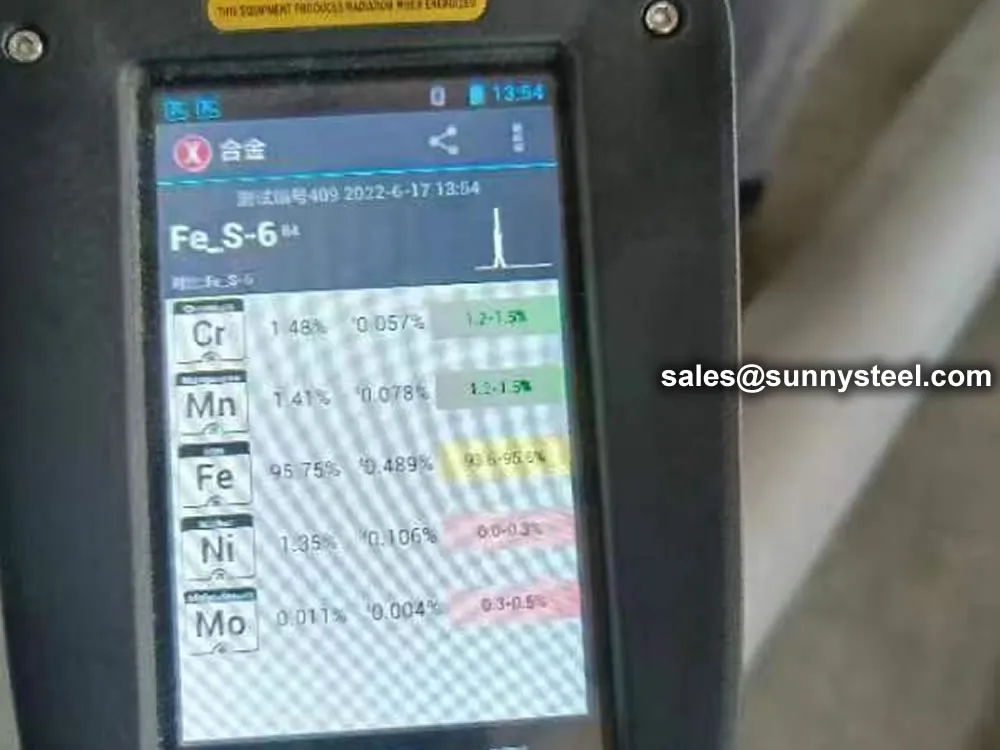

This rare earth alloy steel contains chromium, molybdenum, nickel, and rare earth elements to enhance strength, toughness, and corrosion resistance.

Commonly used in boiler tubes, heat exchangers, and high-pressure pipelines, it withstands creep, corrosion, and thermal cycling in extreme service conditions.

While offering excellent performance, its specialized composition makes it better suited for heavy-duty applications rather than general use.

Abrasive wear is the most severe form of wear, occurring when hard particles cut or gouge metal surfaces—causing plastic deformation, scratches, and eventual erosion.

Allwey's new high-strength rare earth wear-resistant material is developed based on this principle, targeting the root cause of wear-related failures.

Fundamentally solves leakage accidents (coal, oil, air, and ash leakage) that occur during the operation of coal crushing, grinding, and powder feeding equipment in:

Advanced multi-alloy design combining extreme wear resistance, corrosion protection, and ease of installation for pneumatic conveying, slurry pumping, and ash/slurry handling systems.

Under identical conditions, wear volume is only ~1/3 of high-manganese steel, delivering 2–3× longer service life than traditional wear-resistant materials.

R-α carbide structure + high Cr + Mo + rare earth elements create a dense protective oxide film. Excellent performance in high-temperature, acidic, or corrosive environments. Boron increases surface hardness beyond carburizing limits while manganese improves fatigue strength.

Straight pipes withstand >6 kg/cm²

Hot-pressed elbows safely operate at >10 kg/cm²

No air leakage or material deviation in pneumatic systems.

Ideal for coal pulverizing, ash removal, slag discharge, dredge scrapers, spiral conveyors — environments where bimetallic composites fail.

Centrifugal casting + EPC vacuum suction process ensures high dimensional accuracy, uniform microstructure, and stable performance — even for complex shapes like spiral pipes and coal mixers.

| C | Cr | Mn | Mo | Ni | Si | S | P | Re | Tensile σb (MPa) | Impact ak (J/cm²) | Hardness (HRC) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.35–0.42 | 1–1.14 | 1–1.14 | 0.3–0.6 | 0.5–0.8 | 0.8–1.2 | ≤0.04 | ≤0.04 | ≤0.02 | ≥860 | 30 | ≥40 |

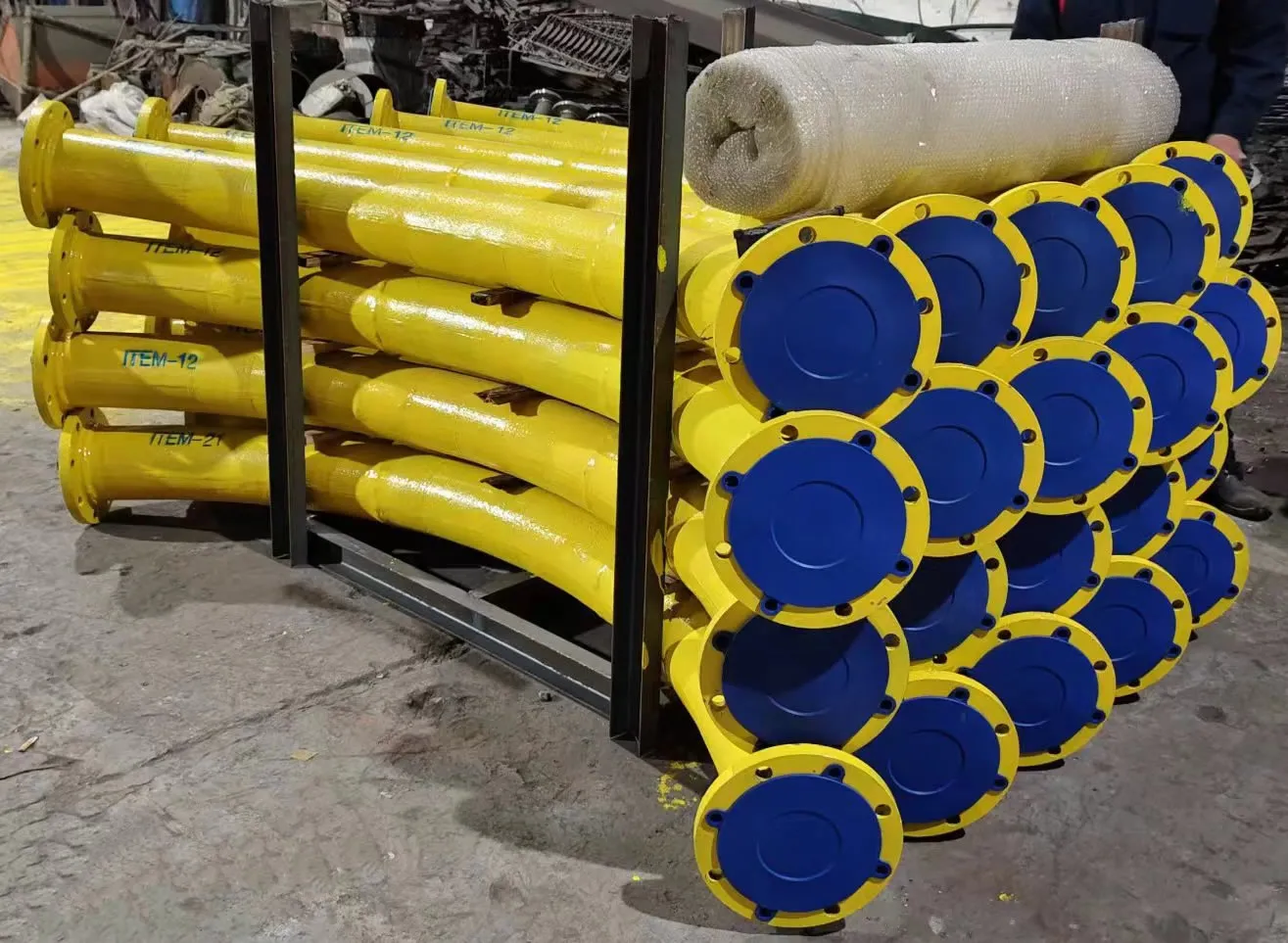

Abrasion-resistant pipes are securely packaged with steel frameworks and sealed with plastic end caps to prevent dust and moisture from entering, ensuring the product remains clean and presentable upon arrival.

Protective measures such as vibration-damping and waterproof covers are implemented to safeguard the pipes during transportation. Each package is clearly labeled and suited for long-distance maritime shipping.

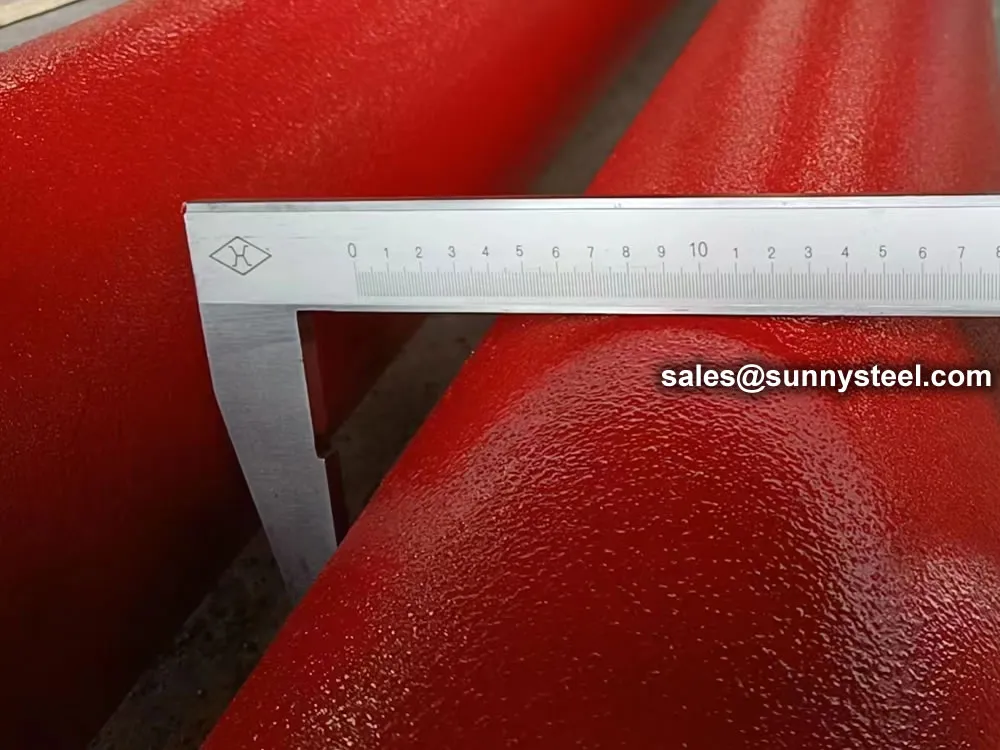

Each pipe undergoes strict dimensional inspection before packaging.

Our packaging solutions protect the pipe structure from mechanical shock and corrosion during international transport.

The end caps of the pipes are rigorously checked for any damage during shipping.

Our packaging solutions protect the pipe structure from mechanical shock and corrosion during international transport.

Pipes are securely arranged and labeled for final shipment to ensure safe arrival.

Our packaging solutions protect the pipe structure from mechanical shock and corrosion during international transport.

Rare‑earth alloy wear‑resistant pipes are produced using horizontal centrifugal casting. Molten alloy is poured into a spinning cylindrical mold (800–1,000 rpm), where centrifugal force distributes metal against the mold walls, forming a dense, uniform structure.

Ideal for long, seamless tubular parts like sleeves and pipes.

Centrifugal force pushes slag and porosity to the inner bore, resulting in a cleaner, stronger outer structure.

Solidification begins from the outer mold inward, enhancing metallurgical properties.

Wall thickness is controlled by metal volume; length is limited only by mold and facility size—up to 6 m or more.

This process delivers pipes with uniform density, refined grain structure, and high mechanical integrity—perfect for wear‑resistant, high‑temperature, and high‑pressure applications.

Designed for slurry transport, pneumatic delivery, and extreme industrial conditions, offering superior wear, heat, and corrosion resistance.

Only 1/3 the unit wear of high manganese steel under the same conditions. Service life is 2–3× longer, reducing replacement frequency.

Rare earths and Mo enhance high-temp and corrosion performance. Boron boosts hardness, while Mn increases fatigue resistance.

Withstands up to 6–10 kg/cm² pressure. Special elbows made via hot pressing and precise welding avoid leakage or material diversion.

Ideal for parts where bimetallic pipes fail—e.g., dredge scrapers, coal mixers, spiral tubes—used widely in power generation systems.

Combines centrifugal casting, resin sand, and EPC vacuum casting for uniform structure, high precision, and long-term reliability.

While highly wear-resistant, the material has lower impact resistance. Handle with care during transport and installation to avoid damage.

Rare Earth Alloy Wear Resistant Pipe Bending

Sort:0

High Strength Low Alloy Rare Earth Wear Resistant Steel Pipe

Sort:0

Rare Earth Wear Resistant Alloy Elbow with Flange

Sort:0

Rare Earth Alloy Wear Resistant Multi-Way Pipe

Sort:0

Rare Earth Alloy Wear Resistant Backpack Elbow

Sort:0

ZG40Cr8MnMoNiSiRe Alloy Cast Steel

Sort:0

Rare Earth Alloy Wear Resistant High Chromium Cast Iron Pipe

Sort:0

JM6A Alloy Wear Resistant Elbow

Sort:0

Rare Earth Wear Resistant Alloy Tee

Sort:0

Rare Earth Alloy Wear Resistant Elbows

Sort:0

Rare Earth Alloy Coal Mill Spiral Tube

Sort:0