Tag#for Thermal Transfer Tubes Get: 19 results / Total 2 pages

L, ll, and kl finned tubes optimize heat transfer in exchangers with robust, corrosion-resistant designs.

Laser welded finned tubes enhance heat exchanger efficiency with high-precision laser welding, offering 99%-100% bond strength and superior corrosion resistance. ideal for petrochemical and power applications, they ensure reliable boiler pipeline protection.

Longitudinal finned tubes boost heat transfer efficiency in exchangers with welded fins, offering corrosion resistance for petrochemical and boiler applications. ideal for high-temperature, high-pressure systems.

High fin tubes maximize heat transfer efficiency in industrial exchangers with tall, welded fins. offering robust corrosion resistance, they are ideal for petrochemical, power generation, and air-cooled applications.

Helical solid finned tubes enhance heat transfer efficiency in industrial exchangers with welded spiral fins. designed for corrosion resistance, they excel in petrochemical, boiler, and power generation applications.

Customized bend extruded fin tubes enhance heat exchanger performance with tailored, bimetallic aluminum fins, offering up to 10 times better thermal transfer and superior corrosion resistance for petrochemical and power applications.

L type finned tube for heat exchanger is a type of finned tube used in heat exchangers to increase the surface area for heat transfer between the fluid inside the tube and the fluid outside the tube.

Integral low fin tubes optimize heat transfer in compact exchangers with seamless, low-height fins. offering corrosion resistance, they are ideal for petrochemical, refrigeration, and power generation applications.

Stainless steel fin tubes optimize heat exchanger efficiency with corrosion-resistant fins, enhancing thermal transfer by up to 10 times. perfect for petrochemical, power, and hvac systems, they ensure durable boiler pipeline protection.

Serrated finned tubes boost heat exchanger efficiency with high-frequency welded spiral fins, enhancing thermal transfer by up to 8 times. offering corrosion resistance, they are ideal for petrochemical and power applications.

Extruded finned tubes enhance heat exchanger efficiency with bimetallic aluminum fins, offering superior corrosion resistance and up to 10 times better thermal transfer. ideal for petrochemical and power applications, ensuring reliable boiler pipeline protection.

Crimped fin tubes enhance heat transfer efficiency in air-cooled exchangers with spiral-wound fins. offering corrosion resistance, they are ideal for petrochemical, hvac, and power generation applications.

Bimetal clad pipe is cast with mold vanishing vacuum suction casting cladding process.

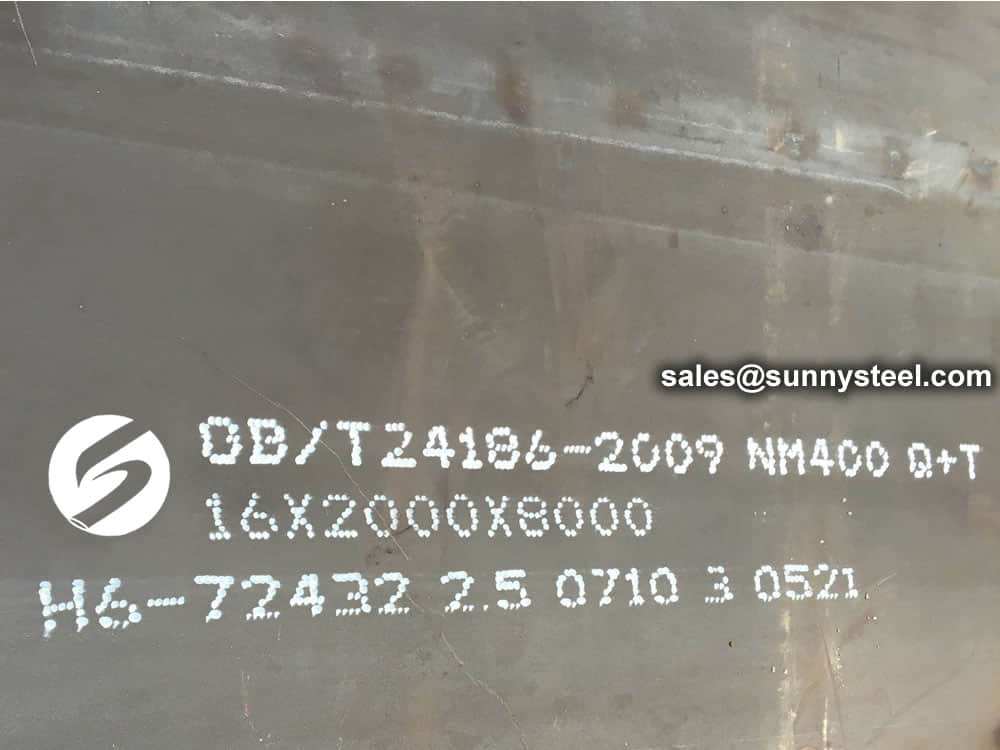

NM400 Steel Plate is a type of wear-resistant steel plate that is commonly used in various industrial applications.

Ceramic tile lined pipes are pipelines that have a ceramic tiles lining layer inside a steel pipe.

The wear resistance of the pulverized coal conveying pipeline of the boiler of the thermal power plant must be designed for leakproof, anti-corrosion, rain-proof, anti-freeze and other factors.