High-performance T91 Alloy Steel Tubes For Elevated Temperature Boiler Systems

Astm a213/asme sa213 t91 alloy steel boiler tubes are ideal for high-temperature service, offering superior creep strength, thermal stability, and corrosion resistance.

High-performance T91 Alloy Steel Tubes For Elevated Temperature Boiler Systems

Astm a213/asme sa213 t91 alloy steel boiler tubes are ideal for high-temperature service, offering superior creep strength, thermal stability, and corrosion resistance.

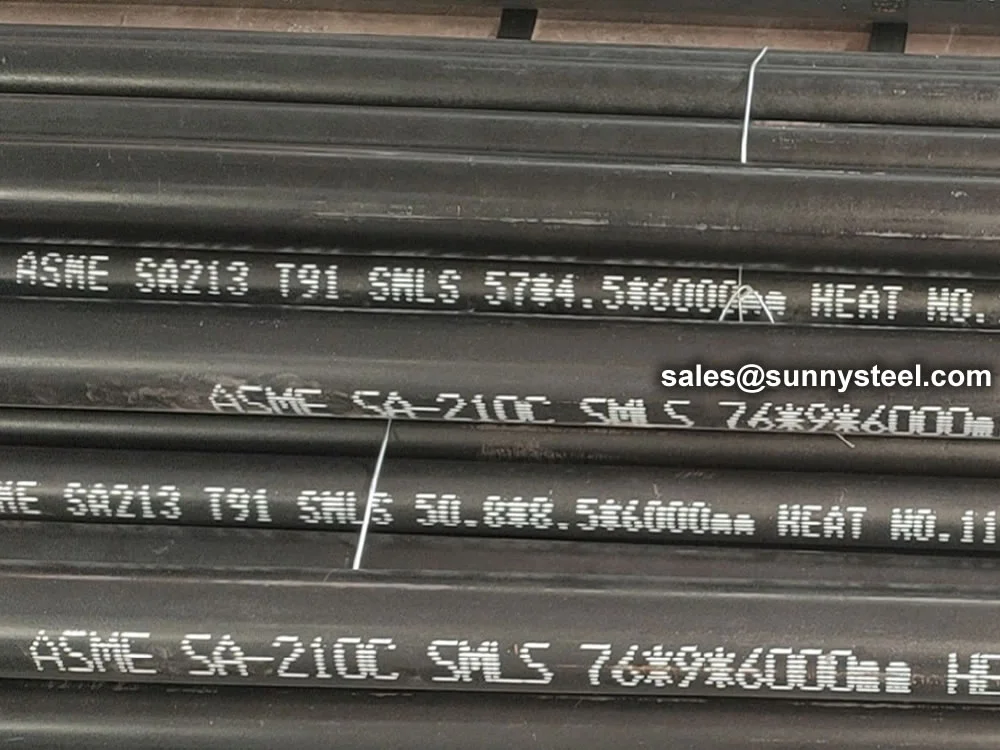

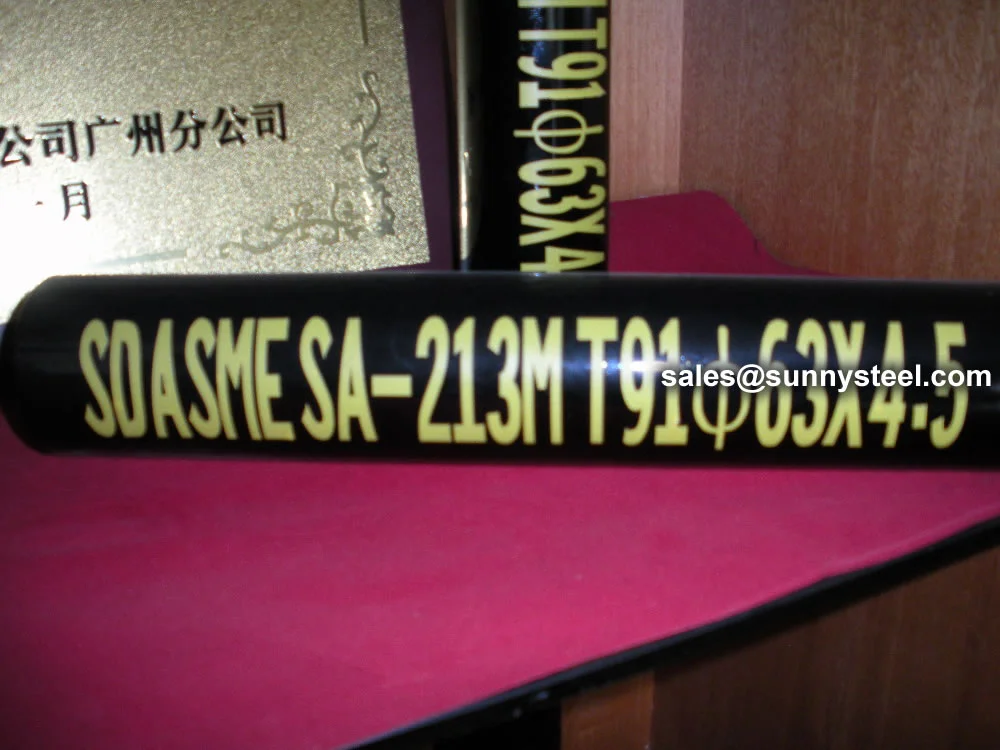

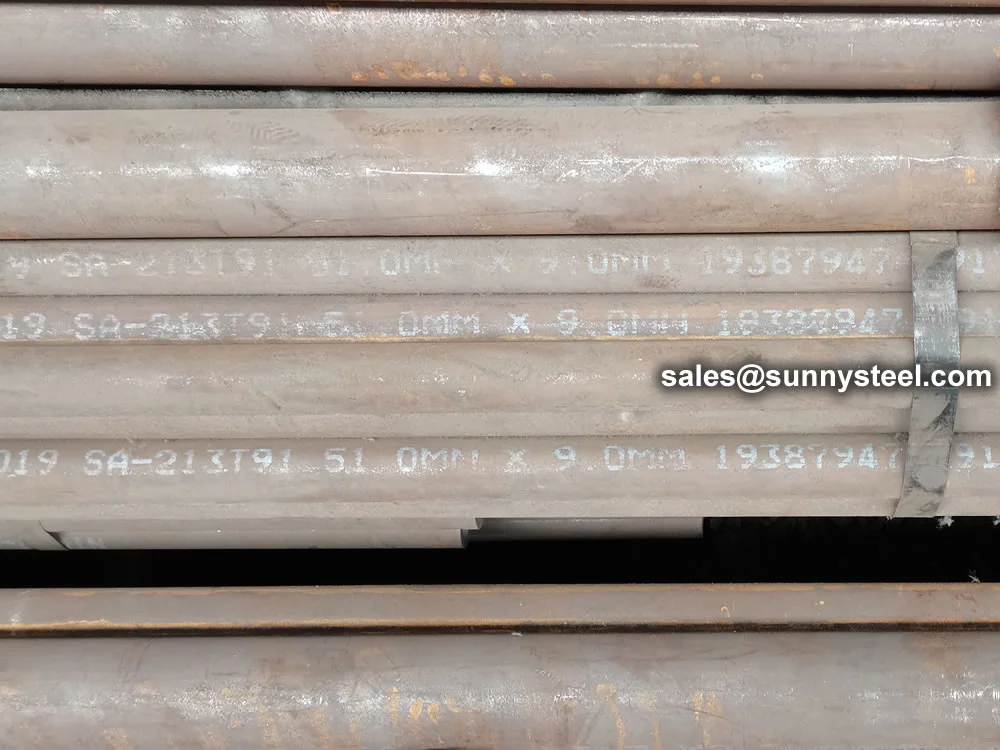

ASTM A213 T91 Seamless Boiler Tubes are premium-grade ferritic alloy steel tubes designed for high-temperature and high-pressure service in boilers, superheaters, and heat exchangers. These tubes offer exceptional creep strength, oxidation resistance, and thermal stability, making them suitable for critical power plant and petrochemical applications.

Manufactured under ASTM A213 and ASME SA213 specifications, T91 alloy steel tubes are produced by cold drawing or hot rolling and then subjected to normalizing and tempering heat treatment. The composition includes Chromium (Cr), Molybdenum (Mo), Vanadium (V), and Niobium (Nb), enhancing the pipe’s structural integrity and corrosion resistance in high-temperature environments.

These seamless alloy steel tubes are extensively used in thermal power stations and industrial boilers where prolonged exposure to temperatures up to 650°C is required. They maintain high mechanical strength and resist hydrogen embrittlement and stress corrosion cracking, meeting the rigorous demands of modern energy systems.

Available in sizes ranging from 1/2" to 5" OD, with wall thickness from 2 mm to 12 mm and lengths up to 12 meters, these tubes support bending, flanging, and welding processes. Their long service life and low maintenance cost make them a preferred choice for high-efficiency boiler systems.

Dimensions and performance data for ASTM A213/SA213 T91 Seamless Alloy Steel Boiler Tubes

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.08-0.12 |

| Manganese (Mn) | 0.30-0.60 |

| Phosphorus (P) | ≤0.020 |

| Sulfur (S) | ≤0.010 |

| Silicon (Si) | 0.20-0.50 |

| Chromium (Cr) | 8.00-9.50 |

| Molybdenum (Mo) | 0.85-1.05 |

| Vanadium (V) | 0.18-0.25 |

| Nitrogen (N) | 0.03-0.07 |

| Property | Value |

|---|---|

| Tensile Strength, min (MPa) | 585 |

| Yield Strength, min (MPa) | 415 |

| Elongation, min (%) | 20 (Longitudinal) |

| Hardness, max (HB) | 217 |

| Parameter | Range | Standard |

|---|---|---|

| Inside Diameter | 1/8" to 5" | 3.2 mm to 127 mm |

| Wall Thickness | 0.015" to 0.500" | 0.4 mm to 12.7 mm |

| Length | 5–7 m / 9–13 m | SRL / DRL |

| Schedule | 40 to 160 | STD, XS, XXS |

| Property | Value | Unit |

|---|---|---|

| Max Service Temperature | 650 | °C |

| Tensile Strength | 415–690 | MPa |

| Yield Strength | 205–520 | MPa |

| Elongation | 20–30 | % |

Key advantages that make ASTM A213 alloy tubes a preferred choice in high-temperature and corrosive environments.

Maintains structural integrity under extreme heat, ideal for boilers, heat exchangers, and superheaters.

Chromium and molybdenum ensure excellent resistance to oxidation and chemical attack in aggressive media.

Offers high tensile and yield strength, ensuring safe performance under high pressure and temperature.

Durable construction and corrosion resistance extend operational life and minimize maintenance downtime.

Precision manufacturing ensures uniform wall thickness and surface finish, optimizing heat transfer and fit.

Widely used in power generation, petrochemical, and thermal processing industries due to its performance and reliability.

ASTM A213/SA213 T91 Seamless Alloy Steel Boiler Tubes are widely used in various industries due to their excellent high-temperature and high-pressure performance.

Utilized in boilers, superheaters, and reheaters within steam power plants due to their high-temperature resistance and durability.

Employed in refineries and chemical plants for transporting high-temperature fluids and gases, ensuring safety and efficiency.

Ideal for use in heat exchangers where thermal stability and corrosion resistance are critical under fluctuating temperatures.

Commonly used in high-pressure boilers and superheaters, offering excellent performance under extreme thermal conditions.

Applied in the extraction and processing of oil and gas, handling high-pressure and high-temperature fluids effectively.

Suitable for equipment in chemical industries where resistance to corrosive substances and high temperatures is essential.

Astm a213 t91 alloy steel boiler tubes offer high ...

Sa213 t91 boiler tubes are seamless alloy steel tu...

Astm a213 t91 seamless alloy tubes offer superior ...