High-temperature Seamless Alloy Tubing

Sa213 t91 boiler tubes are seamless alloy steel tubes for high-temperature power boilers and superheaters, delivering superior strength and oxidation resistance.

High-temperature Seamless Alloy Tubing

Sa213 t91 boiler tubes are seamless alloy steel tubes for high-temperature power boilers and superheaters, delivering superior strength and oxidation resistance.

SA213 T91 Boiler Tubes are seamless ferritic alloy steel tubes developed for high-temperature environments such as superheaters, reheaters, and boilers in power generation and industrial processing applications. These tubes conform to ASME SA213 and ASTM A213 standards, ensuring durability, reliability, and superior mechanical performance in demanding thermal systems.

Designed with enhanced creep strength, T91 alloy steel tubes contain Chromium (8-9.5%) and Molybdenum (0.85–1.05%) for high-temperature stability and resistance to oxidation, while Vanadium, Niobium, and Nitrogen contribute to creep strength and resistance to stress rupture. These features make SA213 T91 the material of choice for ultra-supercritical boilers operating at temperatures exceeding 600°C.

Each tube undergoes strict heat treatment through normalizing and tempering, followed by comprehensive mechanical and nondestructive testing such as ultrasonic inspection, eddy current testing, flattening, and hydrostatic pressure testing. This ensures the tube's structural integrity in high-pressure steam circuits and allows for extended life cycles with minimal maintenance.

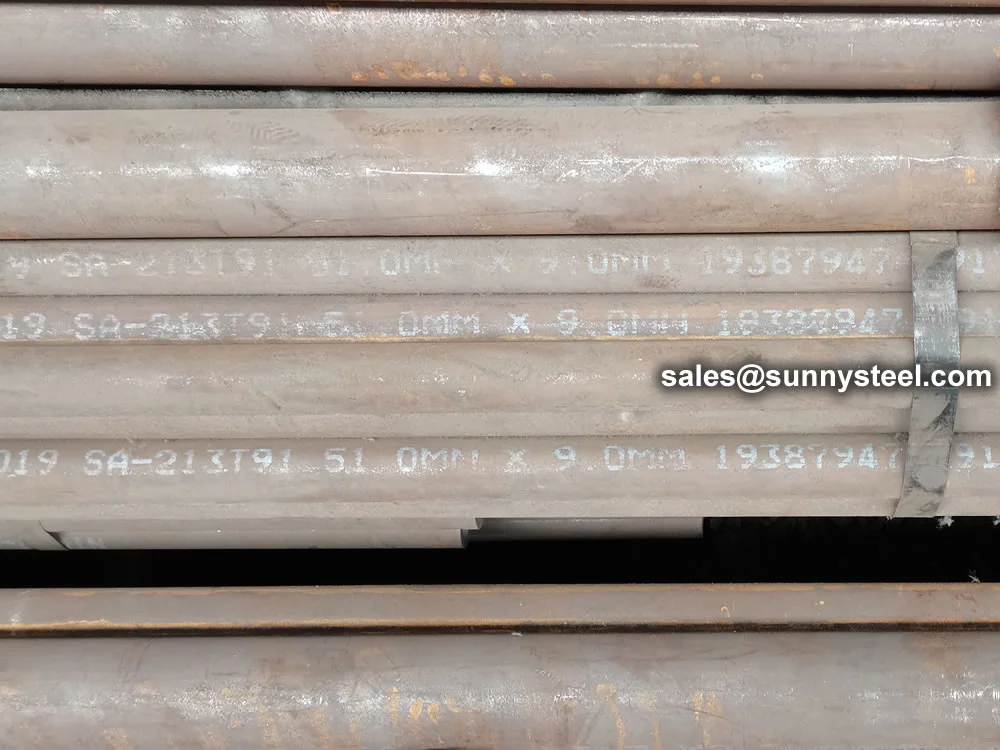

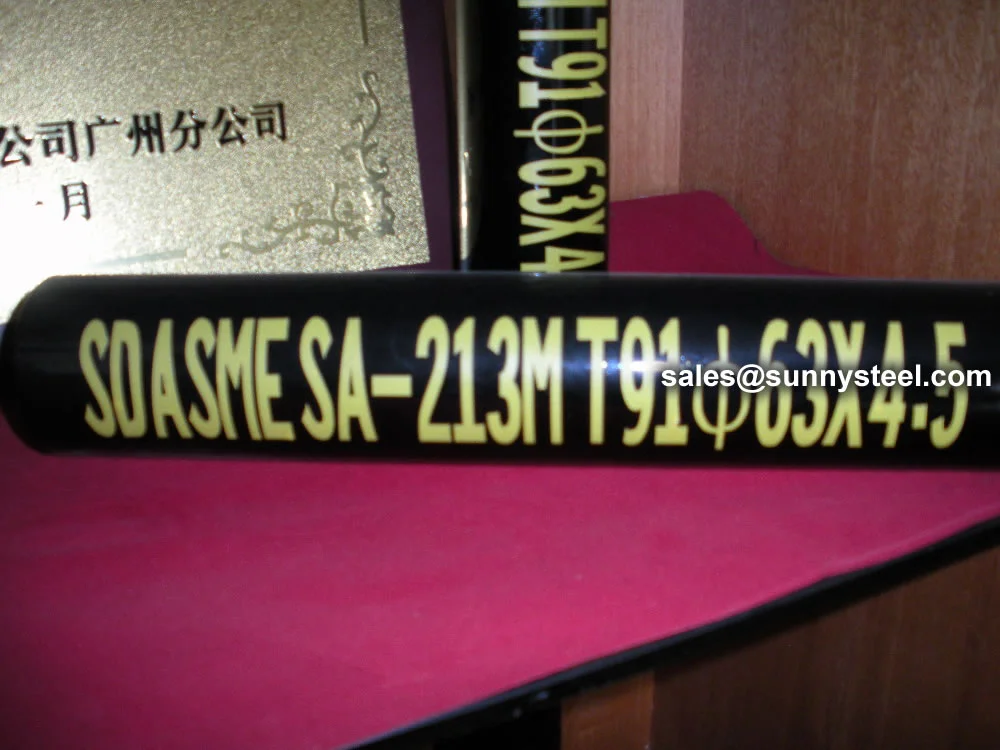

SA213 T91 boiler tubes are available in OD sizes from 1/4” to 5” and thicknesses from SCH10 to SCH160. End types include plain, beveled, or grooved ends as per project specifications. They can also be supplied with anti-rust oil, black painting, or 3LPE coatings for additional protection.

In high-efficiency fossil fuel boilers and combined-cycle plants, SA213 T91 seamless tubes reduce thermal fatigue, improve fuel efficiency, and enhance boiler output. These advantages make them ideal for advanced thermal systems, such as reheaters and final superheaters in subcritical and supercritical boiler lines.

T91 has higher chromium (8.0–9.5% vs. 1.0–1.5%), higher molybdenum (0.85–1.05% vs. 0.44–0.65%), and includes vanadium and niobium for superior creep strength. T91 supports higher temperatures (up to 650°C vs. 560°C) and has higher strength (585/415 MPa vs. 415/205 MPa).

T91 has higher chromium (8.0–9.5% vs. 0.8–1.25%), higher molybdenum (0.85–1.05% vs. 0.44–0.65%), and includes vanadium and niobium, offering better corrosion and creep resistance. T91 is suited for ultra-supercritical boilers (up to 650°C vs. 550°C) with higher strength (585/415 MPa vs. 415/220 MPa).

T91 has higher chromium (8.0–9.5% vs. 1.9–2.6%) and similar molybdenum (0.85–1.05% vs. 0.87–1.13%) but includes vanadium and niobium for enhanced creep resistance. T91 supports higher temperatures (650°C vs. 593°C) and has higher strength (585/415 MPa vs. 415/205 MPa).

T91 has similar chromium (8.0–9.5% vs. 8.0–10.0%) and molybdenum (0.85–1.05% vs. 0.9–1.1%) but includes vanadium and niobium for superior creep resistance. T91 has higher strength (585/415 MPa vs. 415/205 MPa) and is suited for ultra-supercritical boilers (up to 650°C vs. 620°C).

T92 is an enhanced version of T91, with added tungsten (1.5–2.0%) and boron (0.001–0.006%) for improved creep strength, but similar chromium (8.5–9.5% vs. 8.0–9.5%) and slightly higher strength (620/440 MPa vs. 585/415 MPa). Both are used in ultra-supercritical boilers (up to 650°C).

T91 has higher chromium (8.0–9.5% vs. 2.2–2.6%) but similar vanadium and niobium, while T24 includes titanium and boron. T91 is suited for ultra-supercritical boilers (up to 650°C vs. 600°C) with similar strength (585/415 MPa).

T91 (ASME SA213) is a seamless tube for heat transfer components (thinner walls, OD 1/8” to 5”), while P91 (ASTM A335) is a pipe for structural and pressure piping (OD 1/8” to 48”). Both share the same 9Cr–1Mo–V–Nb chemistry but are used in different applications.

The ASME SA213 T91 Seamless Alloy Boiler Tube addresses critical challenges like corrosion, creep, and thermal stress in high-throughput boiler systems. Its advanced alloy composition and seamless construction make it a premium choice for engineers seeking durable boiler tubes for supercritical and ultra-supercritical environments.

Dimensions and performance data for SA213 T91 Boiler Tubes

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.08-0.12 |

| Manganese (Mn) | 0.30-0.60 |

| Phosphorus (P) | ≤0.020 |

| Sulfur (S) | ≤0.010 |

| Silicon (Si) | 0.20-0.50 |

| Chromium (Cr) | 8.00-9.50 |

| Molybdenum (Mo) | 0.85-1.05 |

| Vanadium (V) | 0.18-0.25 |

| Nitrogen (N) | 0.03-0.07 |

| Property | Value |

|---|---|

| Tensile Strength, min (MPa) | 585 |

| Yield Strength, min (MPa) | 415 |

| Elongation, min (%) | 20 (Longitudinal) |

| Hardness, max (HB) | 217 |

| Parameter | Range | Standard |

|---|---|---|

| Inside Diameter | 1/8" to 5" | 3.2 mm to 127 mm |

| Wall Thickness | 0.015" to 0.500" | 0.4 mm to 12.7 mm |

| Length | 5–7 m / 9–13 m | SRL / DRL |

| Schedule | 40 to 160 | STD, XS, XXS |

| Property | Value | Unit |

|---|---|---|

| Max Service Temperature | 650 | °C |

| Tensile Strength | 415–690 | MPa |

| Yield Strength | 205–520 | MPa |

| Elongation | 20–30 | % |

Key advantages that make ASTM A213 alloy tubes a preferred choice in high-temperature and corrosive environments.

Maintains structural integrity under extreme heat, ideal for boilers, heat exchangers, and superheaters.

Chromium and molybdenum ensure excellent resistance to oxidation and chemical attack in aggressive media.

Offers high tensile and yield strength, ensuring safe performance under high pressure and temperature.

Durable construction and corrosion resistance extend operational life and minimize maintenance downtime.

Precision manufacturing ensures uniform wall thickness and surface finish, optimizing heat transfer and fit.

Widely used in power generation, petrochemical, and thermal processing industries due to its performance and reliability.

SA213 T91 Boiler Tubes are widely used in various industries due to their excellent high-temperature and high-pressure performance.

Utilized in boilers, superheaters, and reheaters within steam power plants due to their high-temperature resistance and durability.

Employed in refineries and chemical plants for transporting high-temperature fluids and gases, ensuring safety and efficiency.

Ideal for use in heat exchangers where thermal stability and corrosion resistance are critical under fluctuating temperatures.

Commonly used in high-pressure boilers and superheaters, offering excellent performance under extreme thermal conditions.

Applied in the extraction and processing of oil and gas, handling high-pressure and high-temperature fluids effectively.

Suitable for equipment in chemical industries where resistance to corrosive substances and high temperatures is essential.

Astm a213 t91 alloy steel boiler tubes offer high ...

Astm a213 t91 seamless alloy tubes offer superior ...