High-temperature Boiler Systems

Astm a335 p91 chrome moly pipe delivers exceptional high-temperature strength, corrosion resistance, and durability for critical boiler and heat exchanger systems.

High-temperature Boiler Systems

Astm a335 p91 chrome moly pipe delivers exceptional high-temperature strength, corrosion resistance, and durability for critical boiler and heat exchanger systems.

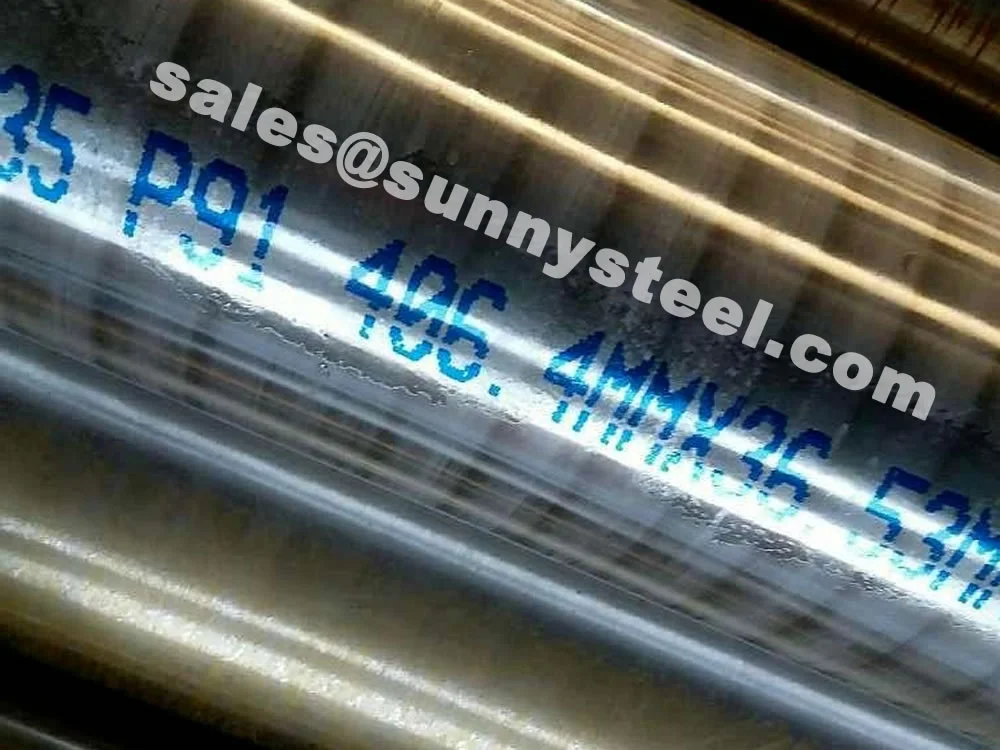

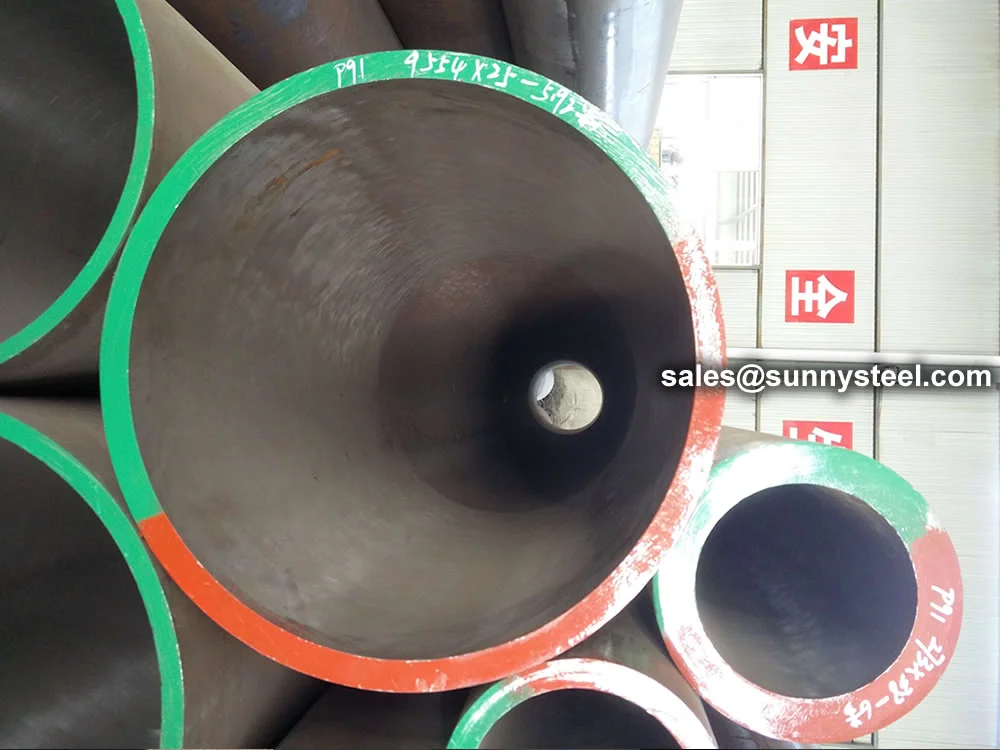

ASTM A335 P91 Alloy Steel Pipe is a seamless ferritic alloy steel pipe formulated for elevated temperature and pressure applications. Also known as Chrome Moly Pipe, it contains approximately 9% chromium and 1% molybdenum with additions of vanadium and niobium to improve strength, oxidation resistance, and structural stability under long-term service.

The P91 pipe is widely used in thermal power plants, superheaters, reheaters, and header lines operating in temperatures ranging from 540°C to 610°C. Its creep rupture strength far surpasses that of earlier grades like P11 and P22, making it the industry standard for ultra-efficient steam systems.

This pipe is manufactured through hot working followed by normalizing and tempering heat treatment to achieve the required mechanical properties. All pipes are subjected to rigorous testing including hydrostatic, hardness, tensile, and ultrasonic inspection to ensure safe operation under extreme service conditions.

Compatible with ASTM A234 WP91 pipe fittings and ASTM A182 F91 flanges, P91 alloy steel ensures complete system consistency in terms of chemical composition, thermal expansion, and pressure rating.

Whether installed in power generation units, refineries, or industrial boilers, ASTM A335 P91 Chrome Moly Pipe offers long-lasting protection against high-temperature corrosion, hydrogen attack, and mechanical fatigue, significantly extending service life and lowering total maintenance costs.

Withstands service conditions up to 610°C without creep rupture failure.

Chromium content protects against corrosion and scale formation in steam environments.

Ensures structural consistency in elbows, tees, reducers, and flanges.

Minimizes failure due to fatigue, thermal stress, and material degradation.

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.08–0.12 |

| Manganese (Mn) | 0.30–0.60 |

| Phosphorus (P) | ≤0.02 |

| Sulfur (S) | ≤0.01 |

| Silicon (Si) | 0.20–0.50 |

| Chromium (Cr) | 8.00–9.50 |

| Molybdenum (Mo) | 0.85–1.05 |

| Vanadium (V) | 0.18–0.25 |

| Niobium (Nb) | 0.06–0.10 |

| Nitrogen (N) | 0.03–0.07 |

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 585 min |

| Yield Strength (MPa) | 415 min |

| Elongation (%) | 20 min |

| Hardness (HBW) | ≤250 |

| Grade | UNS Designation | Chemical Composition % | |||||||

|---|---|---|---|---|---|---|---|---|---|

| P91 Type 1 | K91560 | C | Mn | P | S | Si | Ni | Cr | Mo |

| 0.08-0.12 | 0.30-0.60 | 0.020 | 0.010 | 0.20-0.50 | 0.40 max | 8.00-9.50 | 0.85-1.05 | ||

| V | N | Al | Cb | Ti | Zr | Sn | Sb | ||

| 0.18-0.25 | 0.030-0.070 | 0.02 max | 0.06-010 | 0.01 max | 0.01 max | _ | _ | ||

| P91 Type 2 | K91560 | C | Mn | P | S | Si | Ni | Cr | Mo |

| 0.08-0.12 | 0.30-0.50 | 0.020 | 0.005 | 0.20-0.40 | 0.40 max | 8.00-9.50 | 0.85-1.05 | ||

| V | N | Al | Cb | Ti | Zr | Sn | Sb | ||

| 0.18-0.25 | 0.035-0.070 | 0.02 max | 0.06-0.10 | 0.01 max | 0.01 max | 0.010 max | 0.003 max | ||

ASTM A335 P91 Type 1 & Type 2 have subtle differences mainly in elements Mn, S, Si, N, Sn and Sb content, and Type 2 has stricter requirements on element content than Type 1. P91 type 1 and 2 shall have a hardness within the range of 190 to 250 [HBW] or 196 to 265 [HV] or 91 HRBW to 25 HRC.

P91 (9Cr-1Mo-V-Nb) is a high-performance ferritic alloy steel designed for high-temperature service in power plants and petrochemical systems.

Maintains mechanical performance up to 600°C, allowing reduced wall thickness in steam piping and headers.

Withstands aggressive thermal and chemical environments, supporting advanced boiler design.

Offers up to 10× longer fatigue life compared to conventional steels, reducing shutdowns and failures.

Requires controlled heat treatment to maintain tempered martensitic structure and creep strength.

Chromium, molybdenum, vanadium, and niobium enhance strength, oxidation resistance, and weldability.

Widely used in superheaters, reheaters, HRSGs, and headers with compatible welding consumables.

P91 alloy steel has become the industry standard for high-efficiency power plant systems. It delivers exceptional performance in demanding thermal environments and is essential for systems operating under high pressure and temperature conditions.

ASTM A335 chrome moly pipes are widely used in various industries due to their excellent mechanical properties and resistance to high temperatures.

Used in high-temperature and high-pressure boiler tubes, superheaters, and reheaters for efficient energy conversion.

Applied in refineries and petrochemical plants to transport high-temperature hydrocarbons.

Used in facilities handling corrosive and high-temperature fluids during various chemical reactions.

Employed in nuclear power plants for critical piping systems resistant to extreme heat and pressure.

Used in furnaces and heat exchangers due to excellent resistance to high temperature and thermal fatigue.

Applied in high-pressure steam systems in industries like pulp and paper where thermal durability is essential.

Astm a335 p91 alloy steel seamless pipe offers exc...

Astm a335 p91 alloy steel pipe spool offers superi...

Alloy steel a335 p91 pipes deliver superior creep ...

Astm a335 p91 nace pipe offers superior creep stre...