Get: 31 results / Total 3 pages

Ceramic sleeve lined pipes offer exceptional wear and corrosion resistance, ideal for conveying abrasive materials in mining, power, and chemical industries.

Ceramic sleeve lined fittings provide durable abrasion and corrosion resistance, ensuring longer service life for elbows, tees, reducers, and special joints in aggressive flow systems.

Our ceramic-lined wear resistant pipes offer long-lasting protection against abrasion and corrosion in severe industrial conditions like slurry transport and pneumatic conveying.

Export-grade alumina ceramic sleeve lined pipes provide superior abrasion resistance and durability for australia’s demanding mining and industrial applications.

Alumina ceramic sleeve lined flanged pipes offer high durability and corrosion resistance, combining easy installation with extreme protection in abrasive and chemical flow systems.

Abrasion-resistant alumina ceramic-lined bends provide excellent wear and corrosion protection for pipelines handling abrasive and corrosive media in harsh industrial environments.

Alumina ceramic pipework provides superior protection against abrasion and corrosion, ensuring long-lasting durability in demanding industrial pipeline systems.

High-hardness alumina ceramic lining in elbows and pipes for exceptional wear, corrosion, and thermal protection in industrial pipelines.

Alumina ceramic lining bend pipe for pulverized coal powder conveying offers excellent abrasion protection and smooth flow, ideal for handling abrasive coal powder in power plants and industrial systems.

These 92% alumina ceramic lined steel pipes are built for high-abrasion environments like coal transport, offering unmatched wear resistance and extended service life.

Alumina ceramic lined elbows with loop flanges offer robust wear protection, easy flange connections, and extended service life in abrasive flow systems like slurry, ash, or chemical pipelines.

Alumina ceramic tile lined mining slurry pipes provide excellent wear protection and long service life in abrasive slurry transportation.

Bimetal clad pipe is cast with mold vanishing vacuum suction casting cladding process.

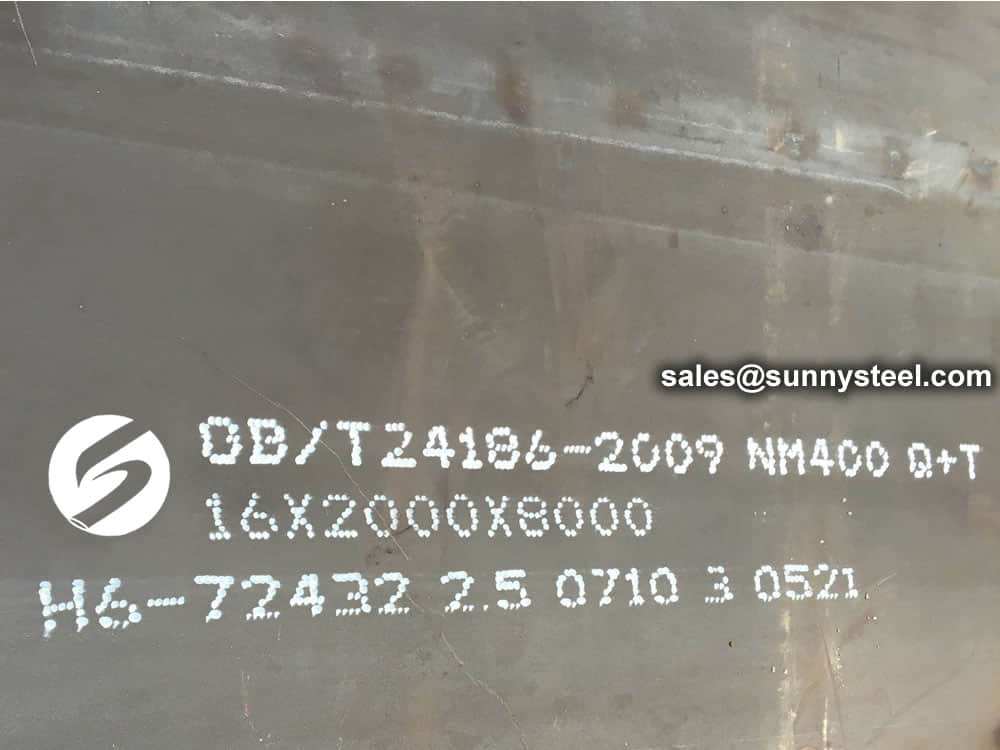

NM400 Steel Plate is a type of wear-resistant steel plate that is commonly used in various industrial applications.

Ceramic tile lined pipes are pipelines that have a ceramic tiles lining layer inside a steel pipe.

The wear resistance of the pulverized coal conveying pipeline of the boiler of the thermal power plant must be designed for leakproof, anti-corrosion, rain-proof, anti-freeze and other factors.