Elite Wear & Corrosion Protection

Highly durable basalt cast lining with superior abrasion, corrosion, chemical, and thermal resistance for industrial pipelines and chutes.

Elite Wear & Corrosion Protection

Highly durable basalt cast lining with superior abrasion, corrosion, chemical, and thermal resistance for industrial pipelines and chutes.

Cast basalt lining is created by pouring molten basalt into molds or centrifuged into pipe segments, producing dense, non-porous linings that offer exceptional protection for industrial ducts, chutes, trays, pipes, and nozzles. The result is a hard, wear-resistant, and chemically inert lining that offers seamless flow and long-term reliability.

Exceptional Wear & Abrasion Resistance

With Mohs hardness of 8+, it withstands particle-laden flows, minimizing erosion and extending equipment life.

Superior Corrosion Resistance

Chemically inert against acids, alkalis, and corrosive slurries found in mining, cement, chemicals, and power industries.

High Thermal Stability

Maintains structure and performance up to 350–400 °C, ideal for hot flue gases and thermal processes.

Smooth Inner Surface & Anti-Clogging

Polished basalt surfaces reduce buildup and friction, supporting uninterrupted material flow.

Non-Magnetic & Inert

Suitable for magnetically sensitive operations, e.g., separators or metallurgical processes.

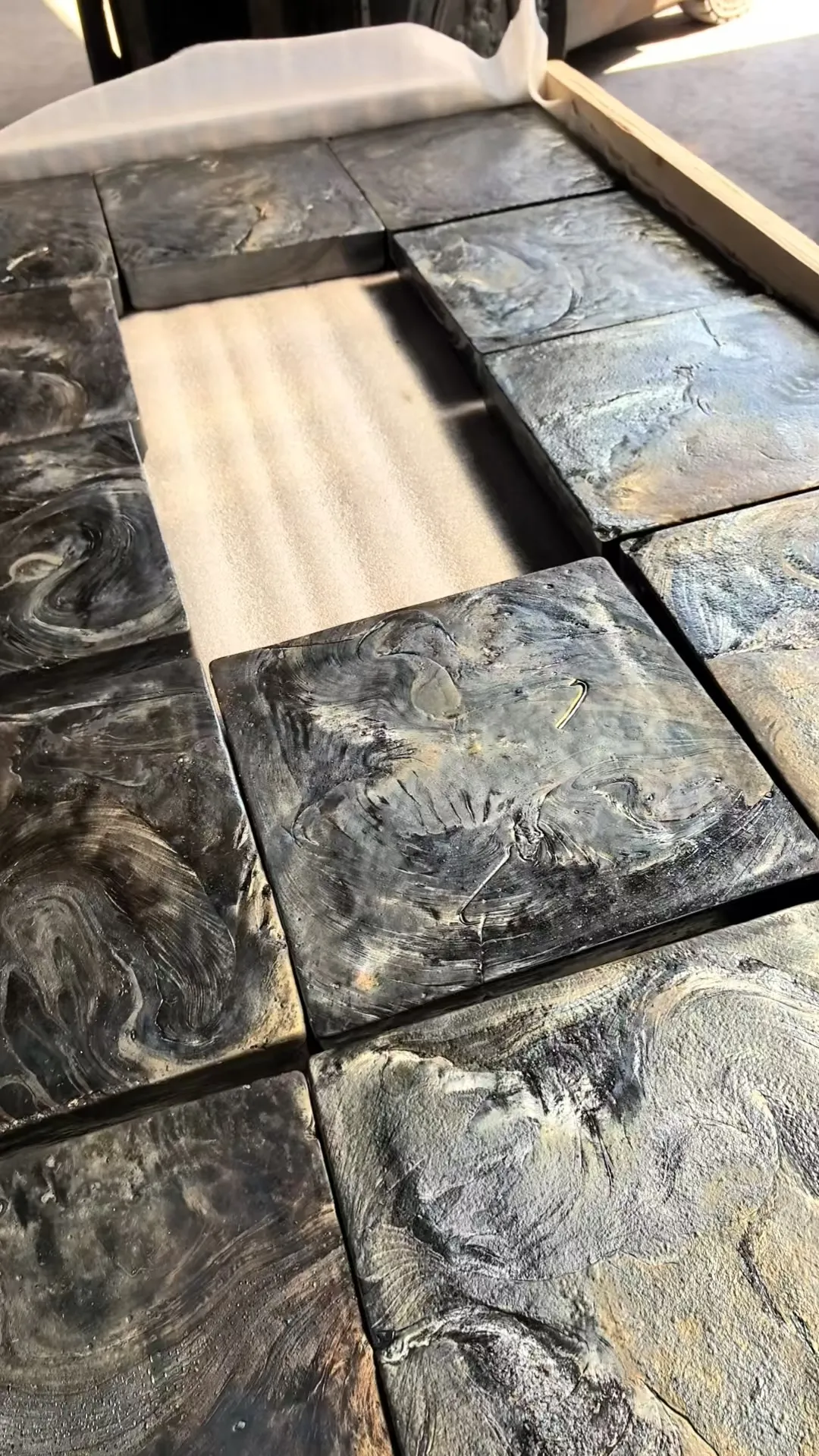

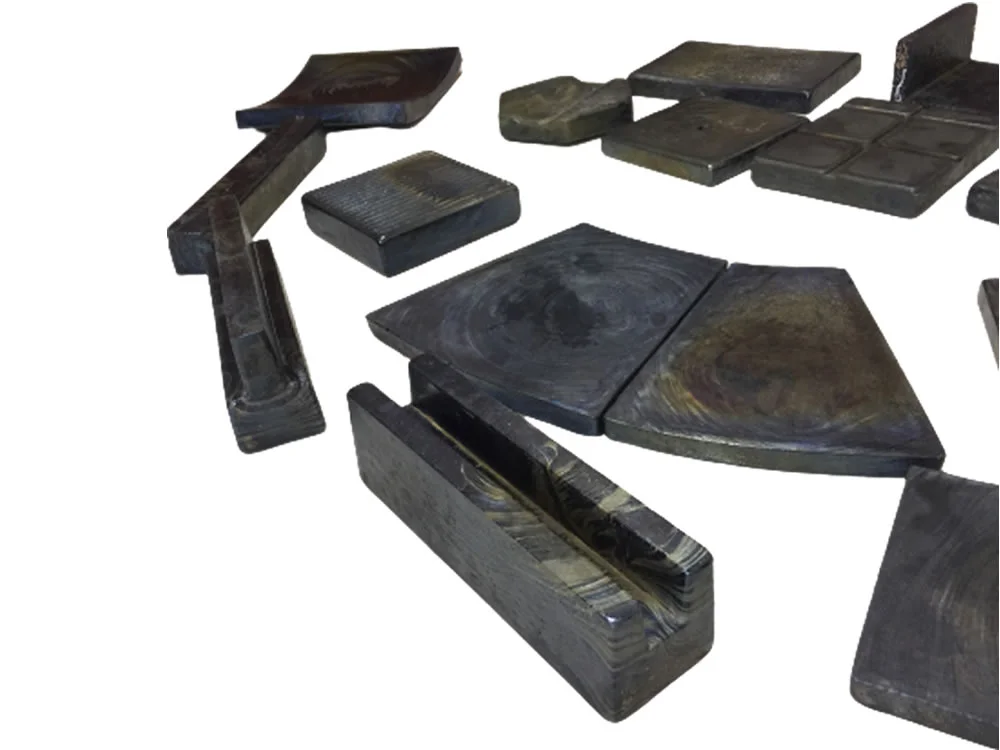

Tiles for Chutes and Trays: Custom-sized (square, rectangular, hexagonal) tiles for modular lining.

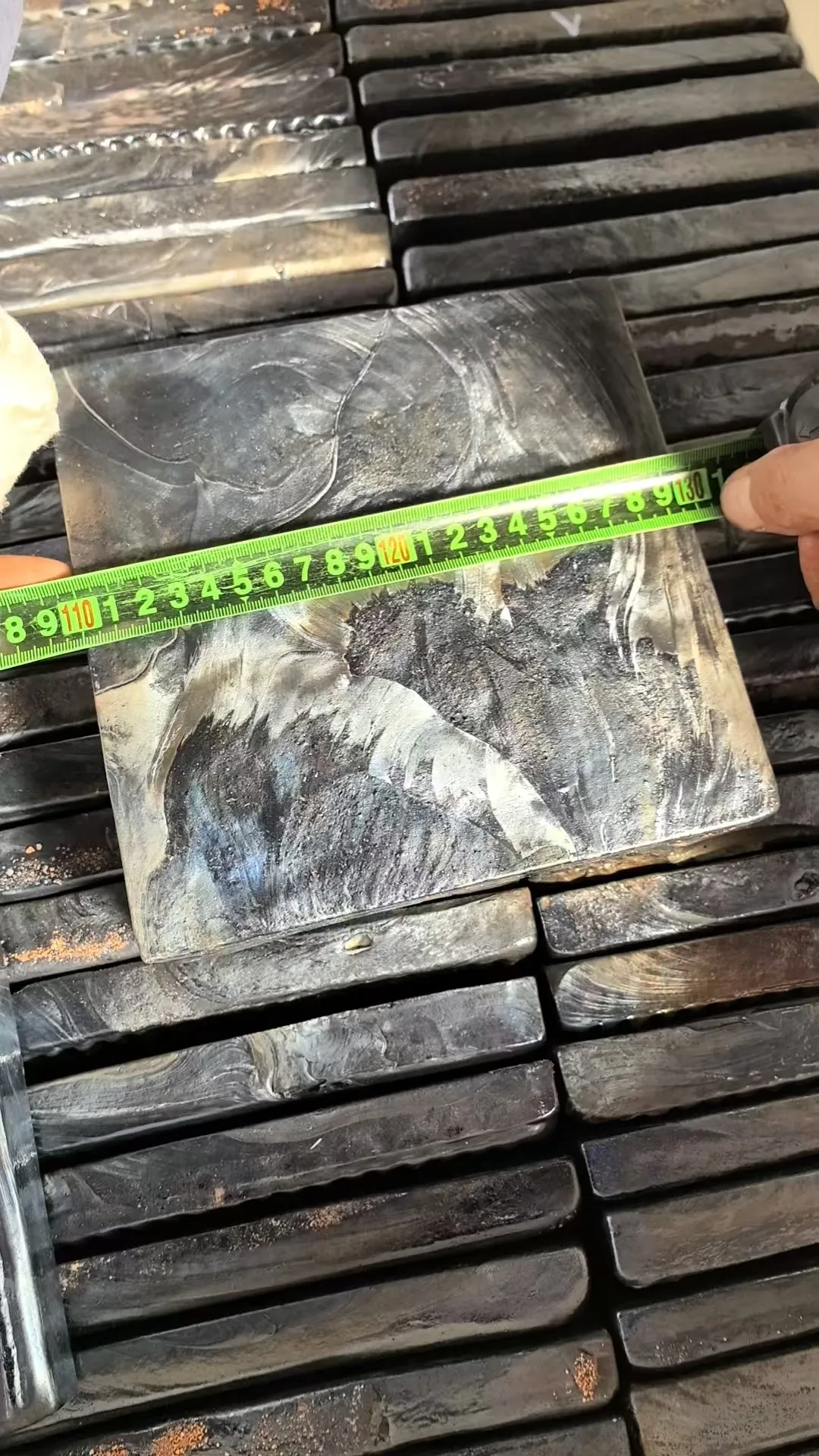

Pipe & Nozzle Segments: Centrifugally cast cylindrical sections for seamless internal lining.

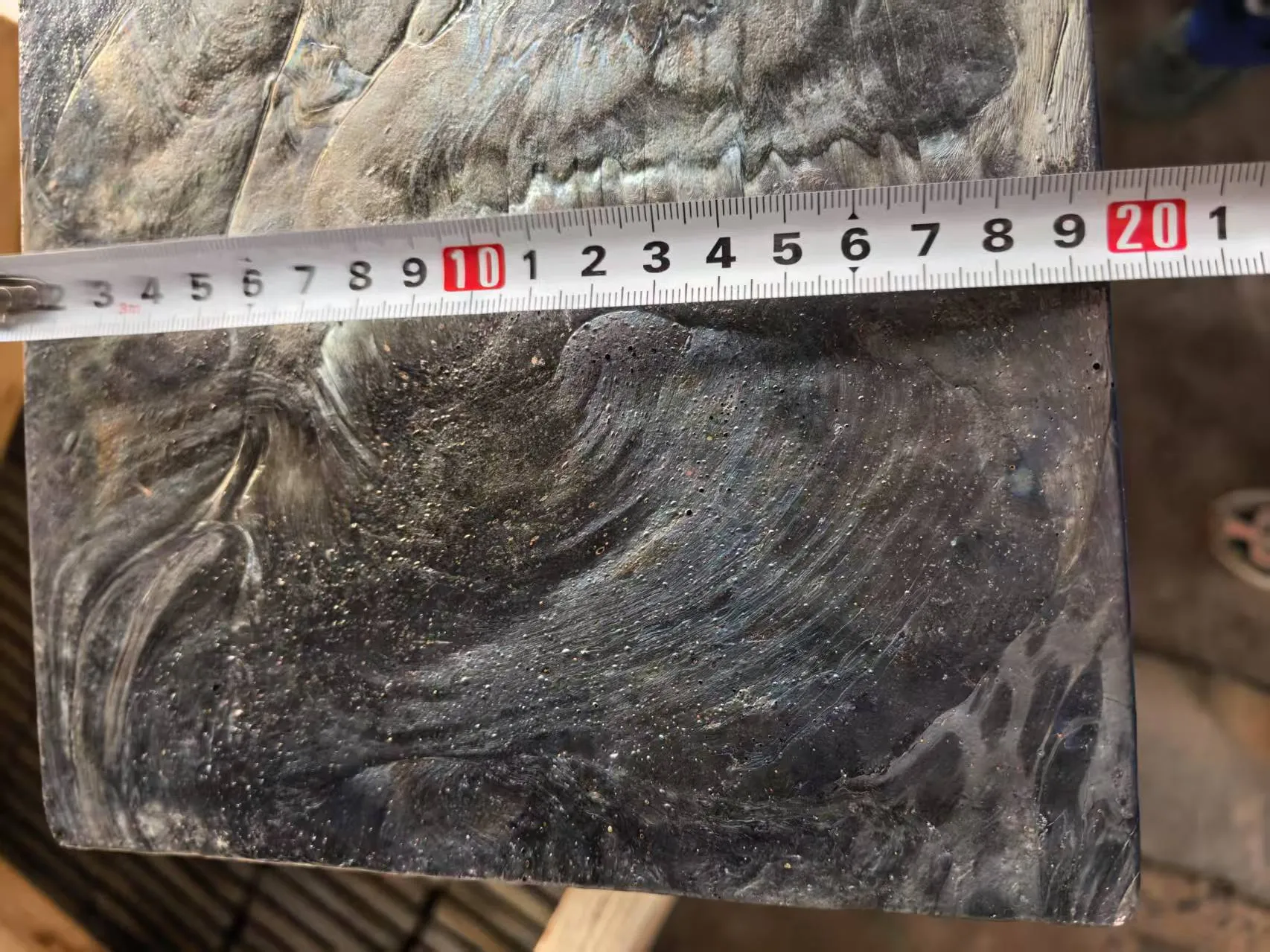

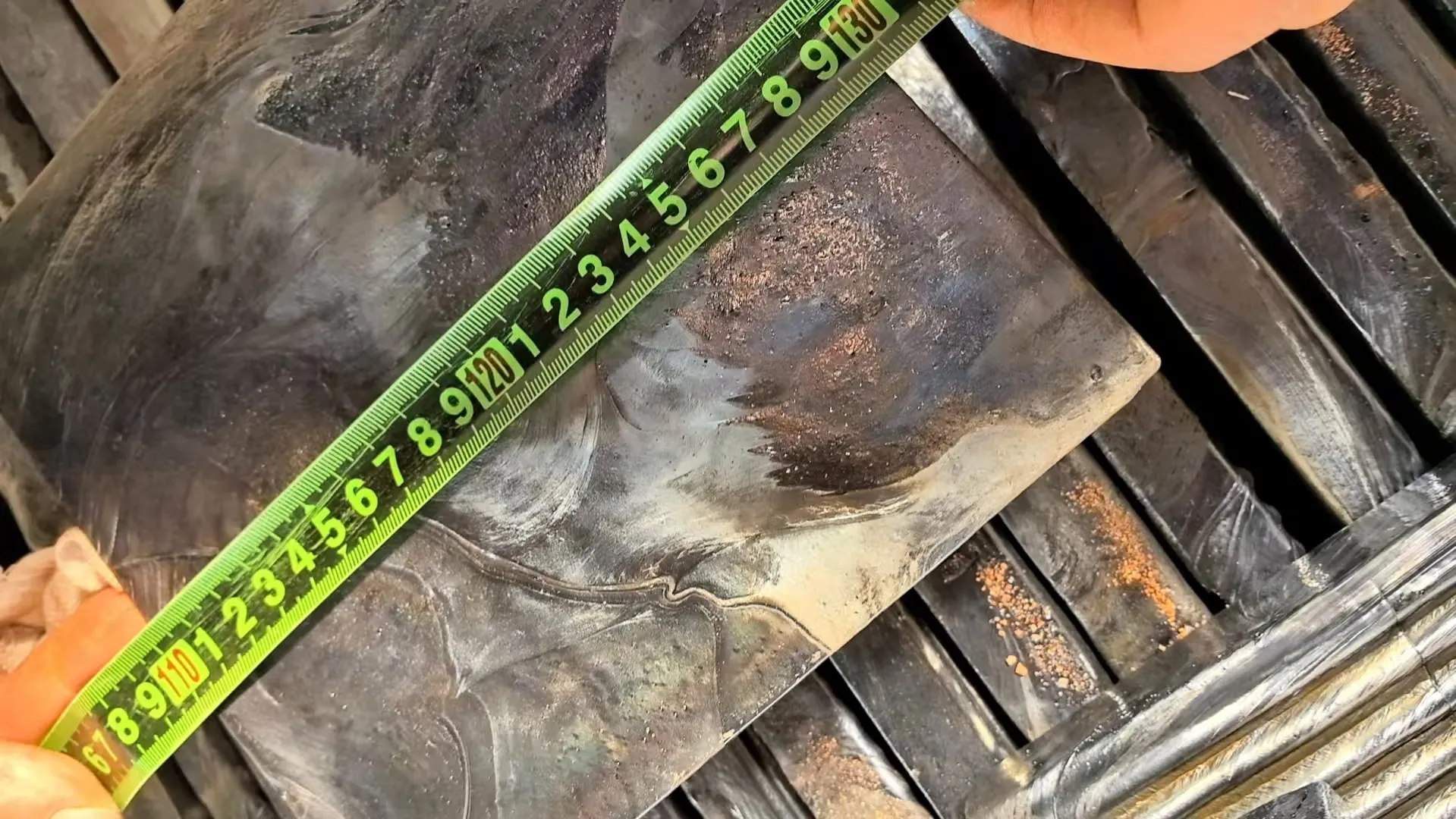

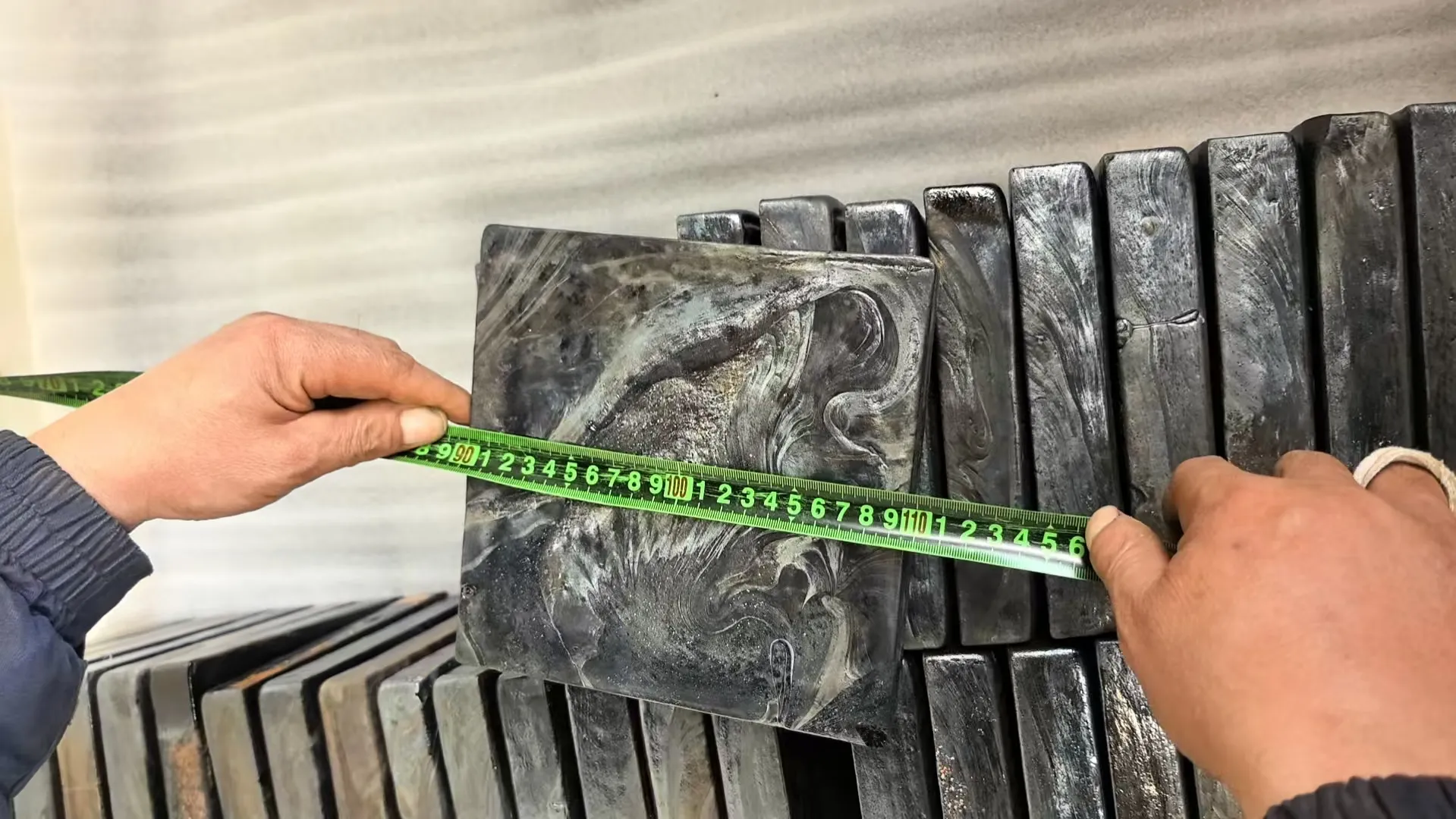

Thickness: Typically 20–30 mm (up to 60 mm on request).

Sizes: Pipes from 32 mm to 600 mm nominal bore; custom segments for any curve.

Mechanical Properties: Mohs ≥ 8, compressive strength ~300–450 MPa, zero water absorption, withstands up to 400 °C.

Inspection cast basalt tiles offer excellent abrasion, chemical, and impact resistance, ensuring long service life for floors, chutes, and lining surfaces.

Inspection cast basalt tiles are high-performance ceramic tiles made from natural volcanic rock that has been melted and cast into precise shapes. After controlled cooling, the material forms a crystalline structure with exceptional hardness (Mohs 8), high compressive strength, and outstanding chemical stability.

Used for Automotive Brake Testing Grounds

Basalt casting was used as a replacement for iron and steel, which were in short supply after WWII. The crushed natural basalt is heated back to molten lava and then poured into molds to make components such as pipes and floor tiles, which are incredibly hard-wearing and abrasion-resistant.

Cast basalt can be formed into a diverse range of shapes and surface patterns, including bespoke designs (min 325m²). During the cooling process, the surface of the material achieves a glass-like patina, with an iridescence and texture that is unique to each piece.

Cast basalt is produced by melting selected natural basalt – broken into sizes of 20–50 mm – in shaft furnaces at temperatures around 1,300°C, followed by casting into the desired molds. Of fundamental importance is the subsequent tempering process, in which the molten basalt forms uniform, spherulitic crystals that contribute to its physical properties such as extreme hardness and abrasion resistance.

Cast basalt is the most frequently used wear protection material. The main areas of application are the wear-resistant linings for:

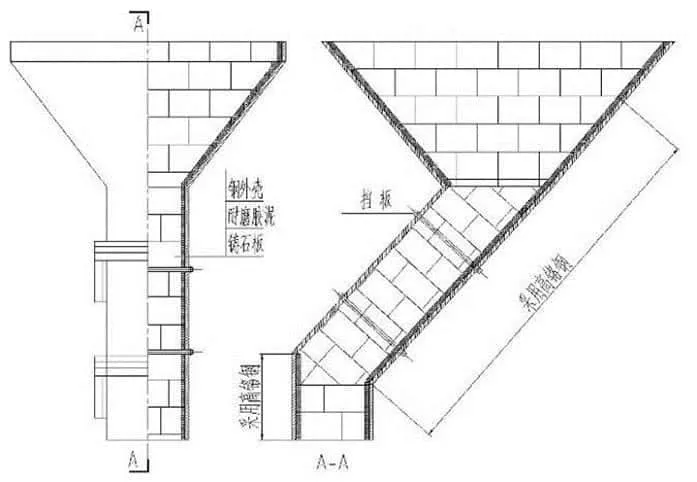

The walls and outlets of bunkers, silos, and other tanks used for the storage of bulk materials are subject to strong abrasive wear. Strong friction wear occurs when emptying is compounded by impact wear during the filling process.

A wear-resistant lining with hexagonal or rectangular cast basalt tiles has proven to be a successful and economical solution. Special form pieces are manufactured for the flutes and the bunker saddles. Circular bunkers and silos are lined with radial, rectangular, or hexagonal form pieces that precisely match the required circumference.

To improve adhesion, corrugated wire mesh is spot-welded to the vertical steel walls.

The transport of abrasive media, in fact of virtually all granular materials, in enclosed pipelines has the advantage that it is non-polluting, generates neither dust nor smell, and even saves valuable space. Completely lined pipes can be manufactured with the following maximum lengths:

Cast basalt lined piping is extremely wear-resistant and is used wherever highly abrasive materials are conveyed pneumatically or hydraulically, for example:

Everything you need to know about Basalt Tiles

Basalt is the new miracle fire-protection material. It is made from volcanic rock and can withstand 2500 degrees for an unlimited time while having 3 times the tensile strength of steel.

Compared with traditional concrete, basalt-fiber-reinforced concrete has the advantages of higher tensile strength and less cracking.

Cast Basalt is a naturally occurring basalt-rock wear-resistant material. Offering superb abrasion resistance, this mineral is quarried, melted, cast, and annealed to form a fine-crystallized glass-ceramic of extreme hardness that resists erosion. Cast Basalt is supplied in pipe and tile form and provides an excellent hard-wearing surface for corrosive wear and abrasion protection of equipment.

Cast basalt tiles are known for their excellent wear resistance and are commonly used in applications where abrasion and corrosion resistance are critical, such as in pipelines, chutes, hoppers, and other high-wear environments. Having these tiles in stock allows for a quick response to customer demands and efficient fulfillment of orders.

Hard & Compact Smooth & Inner Withstands High-Abrasion & Corrosion In any of the process industries especially Sled and Cement corrosion and abrasion lead to significant downtime of the plant. Further, the useful life or the equipment itself may get impaired because of the high abrasive nature of the materials being used. Thus, ‘wear mechanism’ results in hut down, replacement, etc., which is costly, resulting in loss to tilt: tunic of millions of dollars.

Basalt tiles can be placed and jointed in cement or specially-defined bonding agents, as demanded by the intended application. Basalt tiles can be provided with a central hole that is countersunk for individual bolting, or as ready-made liner plates and pipes.

Cast basalt tiles are mainly used in thermal power plants, steel mills, mines and other parts with heavy wear, such as raw coal bunkers, mine bins, coal unloading trenches, hoppers, ore troughs, flotation machines, chutes and other parts.

Used for Automotive Brake Testing Grounds

These very hard tiles are made for very heavy industrial use, but also feature a beautiful metallic sheen. Originally used for sewerage systems or piping pieces, these pavement tiles are made by melting natural basalt and casting it into metal moulds.

Cast basalt pipe shields deliver high-strength wea...

Cast basalt tiles offer extreme hardness, excellen...

Molten basalt linings engineered for pipes, chutes...

Durable basalt lining tiles for bunker walls, chut...

Standard cast basalt tiles offer robust wear, corr...

Preformed half-section basalt linings designed for...