Cast Basalt Aggregate

Durable Industrial Rock Granules

Cast basalt aggregate offers high wear and heat resistance, ideal for producing robust cast basalt products and enhancing concrete with durable volcanic stone granules.

Durable Industrial Rock Granules

Cast basalt aggregate offers high wear and heat resistance, ideal for producing robust cast basalt products and enhancing concrete with durable volcanic stone granules.

Cast basalt aggregate is a dense, wear-resistant material produced by melting natural volcanic basalt rock at approximately 1400°C and casting it into stone before crushing it into granules of specified sizes. These crushed basalt fragments retain excellent mechanical and chemical properties, making them ideal for various demanding industrial environments.

Our durable basalt gravel offers superior performance for versatile infrastructure solutions.

Basalt is a volcanic rock that is formed from the rapid cooling of lava. It is known for its high strength, durability, and thermal resistance, making it suitable for various applications in industries like construction, transportation, and manufacturing.

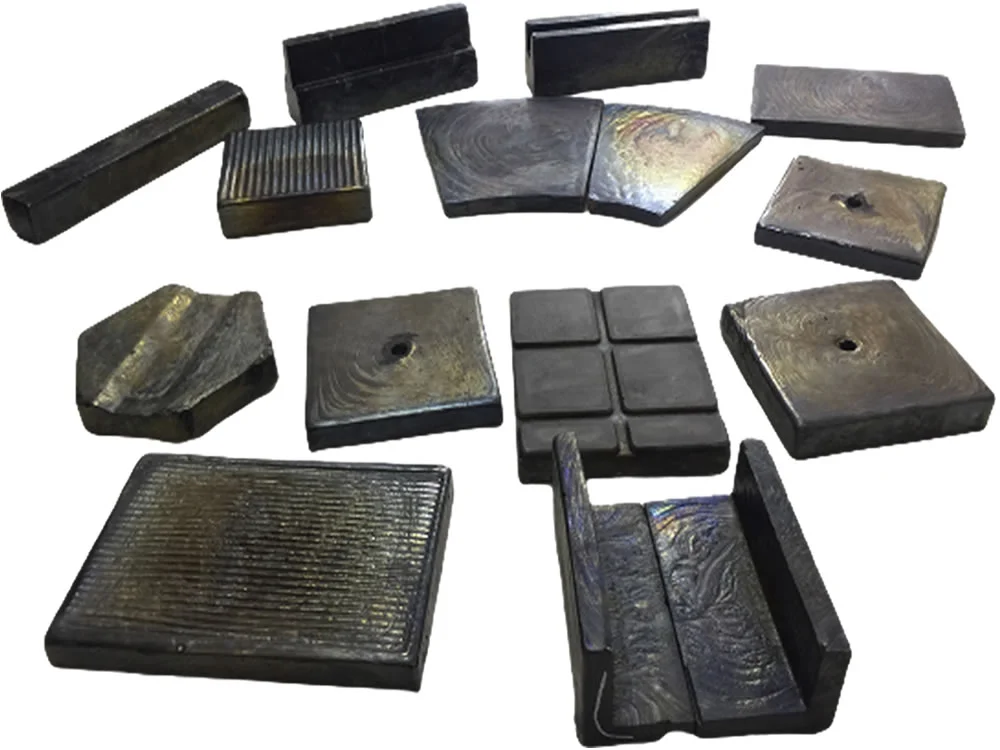

In the production of cast basalt products, such as pipes, tiles, and linings, the basalt aggregate is mixed with a binding agent, usually epoxy resin or cementitious material. The mixture is then cast into a desired shape and cured to form a solid product.

Cast basalt products, reinforced with the aggregate, exhibit excellent resistance to abrasion, corrosion, and impact. They are commonly used in applications where high wear and chemical resistance are required, such as in lining chutes, hoppers, pipelines, and tanks.

Overall, cast basalt aggregate plays a crucial role in the manufacturing of cast basalt products, providing them with the desirable properties that make them suitable for heavy-duty industrial applications.

When it comes to basalt, we generally only know that it is often used to make stone aggregates, and it is an ideal aggregate raw material. But in fact, basalt can also be made into fine powder and used as a mixing material for cement. The effect is ideal, and it can also save coal consumption, which has good economic and social benefits. Guilin Hongcheng basalt vertical mill will introduce you.

Basalt is a good raw material for producing cast stone. Cast stone is a material made of basalt after melting, casting, crystallization, and annealing. It is harder and more wear-resistant than alloy steel, and stronger than lead and .

High-density, abrasion-resistant granules for industrial applications.

Cast basalt lined steel pipe combines steel toughn...

Cast basalt tiles, abrasion-resistant tiles, wear-...

Cast basalt pipes feature high mohs hardness and c...

Cast basalt tile lined pipes deliver durable wear ...