Self‑Propagating Ceramic Pipe Fitting

Ultra‑wear Composite

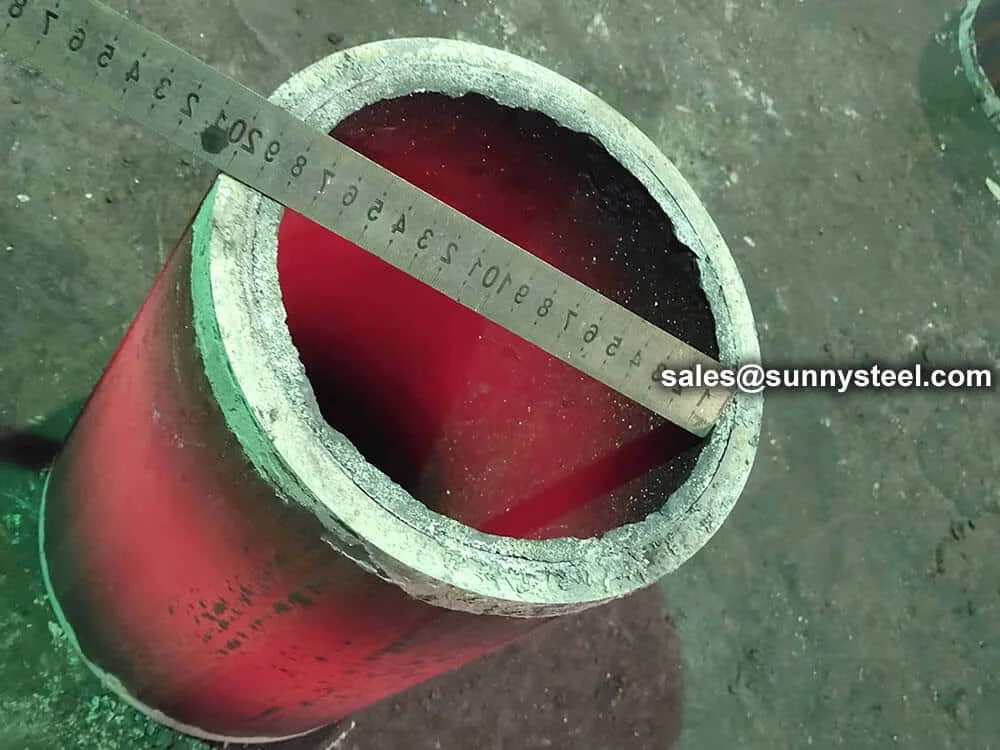

Self‑propagating ceramic pipe fittings feature in-situ shs ceramic linings for 10–20× longer wear life—ideal for elbows, tees, and reducers in abrasive industrial lines.

Self‑Propagating Ceramic Pipe Fitting

Ultra‑wear Composite

Self‑propagating ceramic pipe fittings feature in-situ shs ceramic linings for 10–20× longer wear life—ideal for elbows, tees, and reducers in abrasive industrial lines.