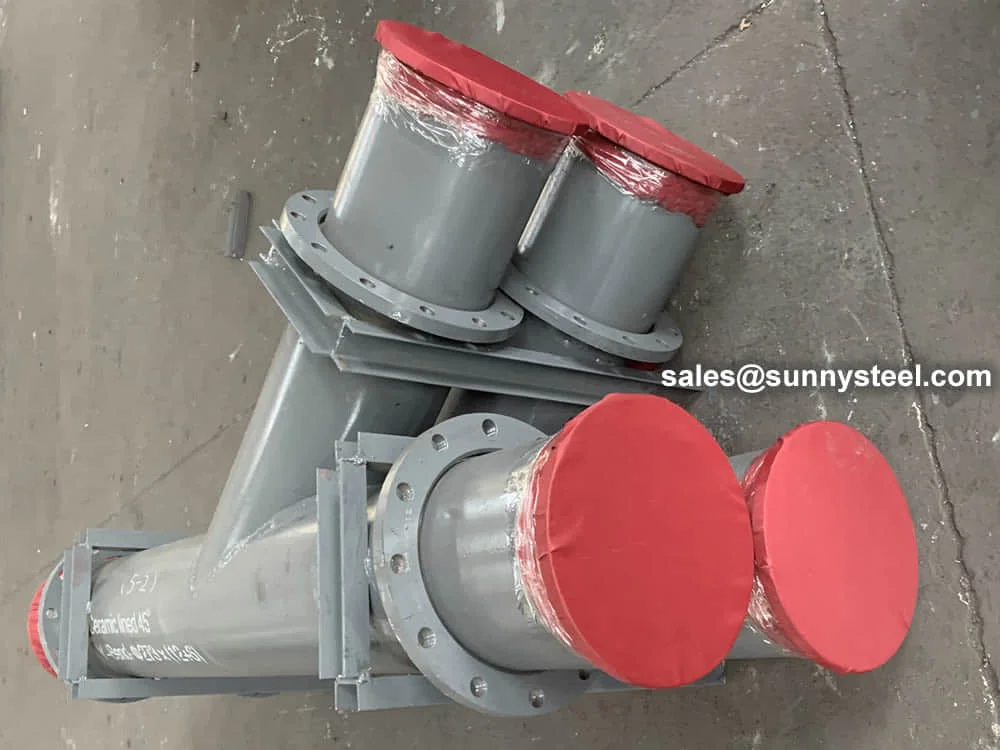

Ceramic‑Lined Lateral (Wye) Pipe

Wear & Corrosion Branch

Ceramic‑lined wye (lateral) pipes offer superior wear, corrosion, and heat resistance—ideal for abrasive slurry, ash, or chemical branching in industrial piping networks.

Ceramic‑Lined Lateral (Wye) Pipe

Wear & Corrosion Branch

Ceramic‑lined wye (lateral) pipes offer superior wear, corrosion, and heat resistance—ideal for abrasive slurry, ash, or chemical branching in industrial piping networks.