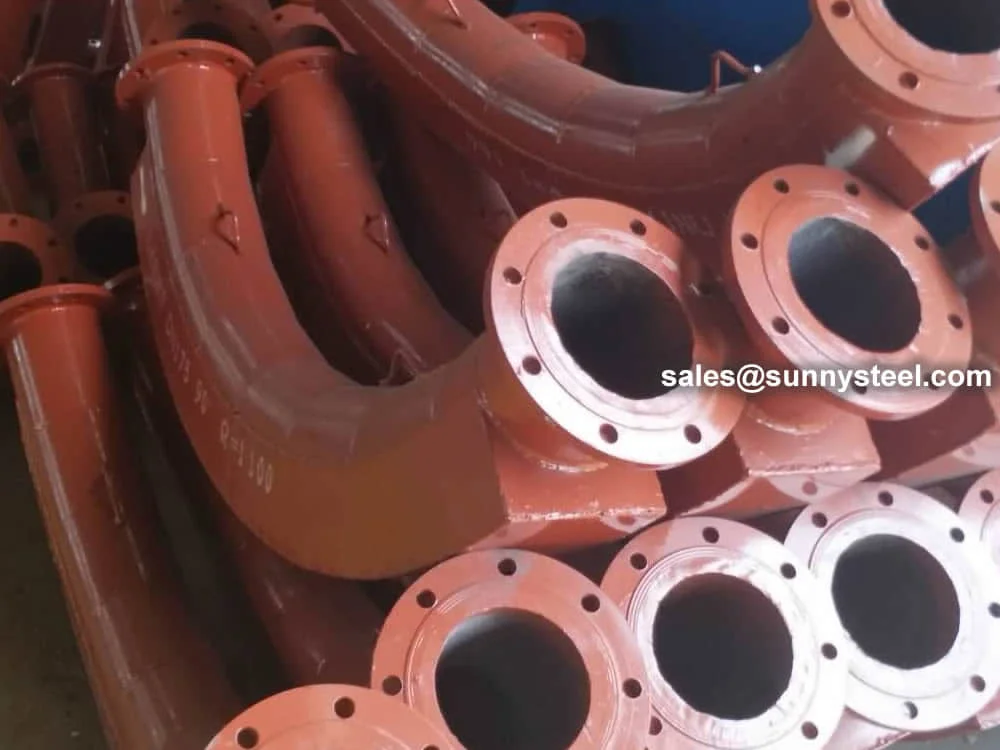

Backpack Ceramic Lined Elbow

Durable Abrasion Protection

Backpack ceramic lined elbow features a 12mm alumina ceramic layer bonded to high-tensile steel, offering 20× longer lifespan vs.

Backpack Ceramic Lined Elbow

Durable Abrasion Protection

Backpack ceramic lined elbow features a 12mm alumina ceramic layer bonded to high-tensile steel, offering 20× longer lifespan vs. standard fittings. ideal for abrasive slurry transport in mining, cement, and ash handling systems. withstands 800°c temperatures and severe impact. custom angles available.