SSiC thermocouple protection tubes are advanced ceramic components manufactured from siliconized silicon carbide (SSiC), a material known for its ultra-high hardness, corrosion resistance, and thermal stability. These tubes are specifically engineered to shield temperature sensors (such as thermocouples) operating in harsh industrial environments.

Thanks to their fine-grain microstructure and dense sintered body, SSiC protection tubes are ideal for applications requiring rapid temperature response, high strength, and long service life under thermal and chemical stress.

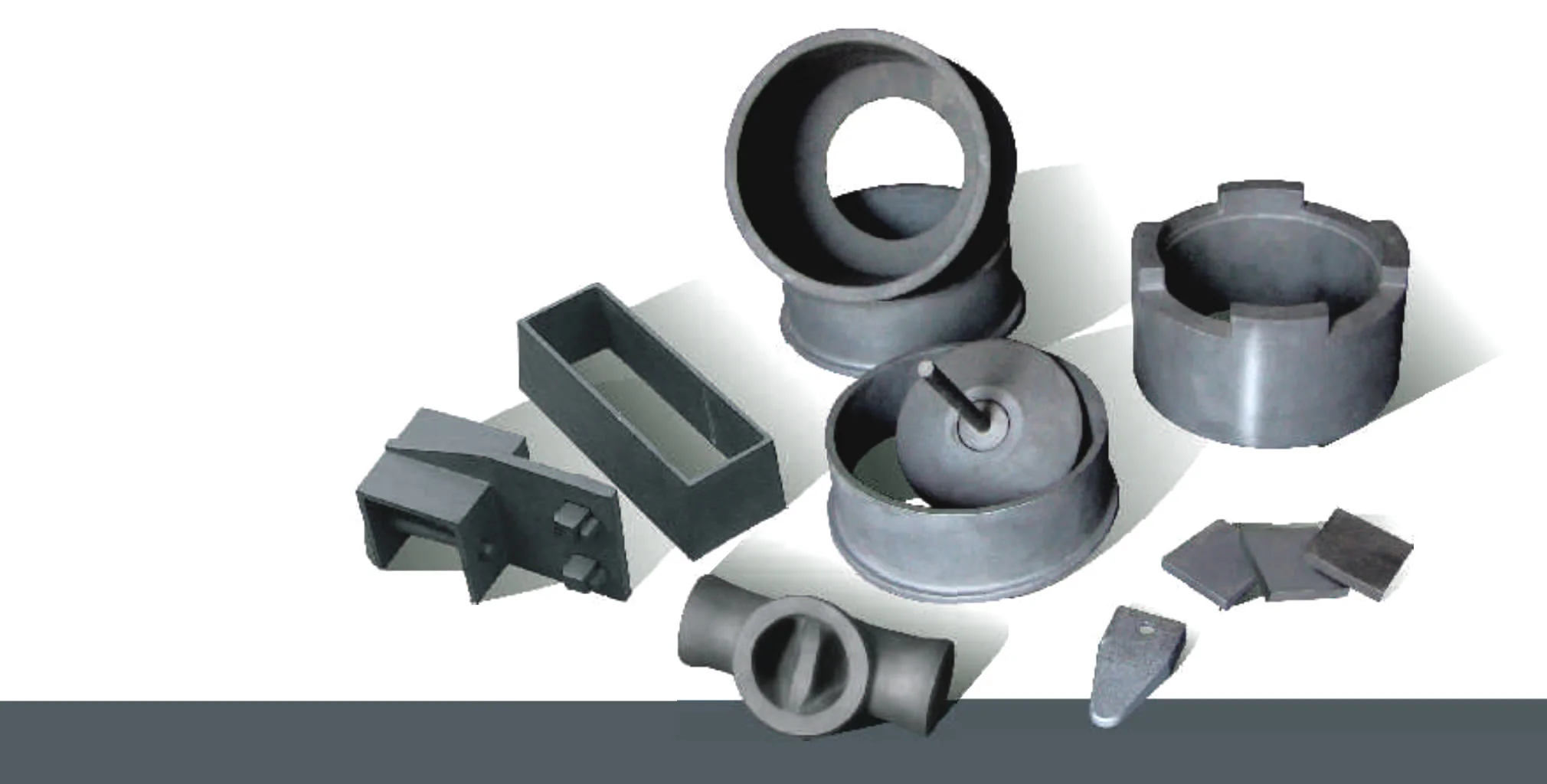

SSiC thermocouple protection tubes are available in a range of lengths, diameters, and closed/open end configurations, with customized options to match different sensor designs and installation conditions.

By using an SSiC ceramic protection tube, industries benefit from extended thermocouple life, stable measurement accuracy, and reduced maintenance downtime, even in the most aggressive service conditions.

SSiC (Silicon Carbide) thermocouple protection tubes are used to safeguard thermocouples from harsh environmental conditions, offering excellent performance in high-temperature, corrosive, and abrasive environments. They are known for their resistance to oxidation, high thermal conductivity, and resistance to thermal shock, making them suitable for demanding applications.

SSiC (Sintered Silicon Carbide) Thermocouple Protection Tubes represent the pinnacle of durability for industrial temperature measurement in extreme environments. These tubes shield sensitive thermocouple sensors from direct contact with corrosive media, thermal stress, and mechanical abrasion while ensuring accurate thermal profiling in processes exceeding 1500°C.