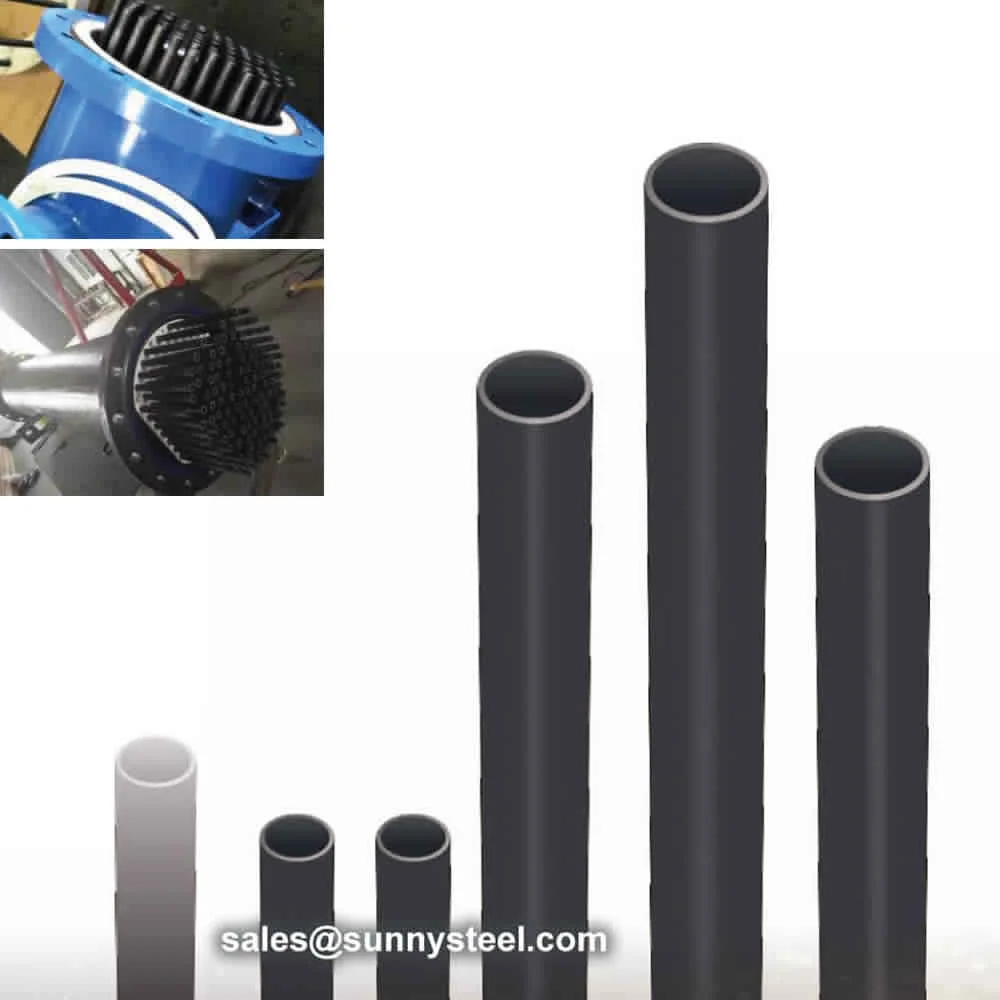

SSiC Heat Exchange Tube

Silicon Carbide For Corrosive & Thermal Systems

Ssic heat exchange tubes deliver outstanding corrosion and thermal shock resistance, ideal for aggressive and high-temperature fluid systems in chemical and thermal industries.

SSiC Heat Exchange Tube

Silicon Carbide For Corrosive & Thermal Systems

Ssic heat exchange tubes deliver outstanding corrosion and thermal shock resistance, ideal for aggressive and high-temperature fluid systems in chemical and thermal industries.