Silicon carbide alloy ceramic elbows offer extreme resistance to wear, corrosion, and thermal shock—ideal for handling abrasive slurries in power, mining, and chemical industries.

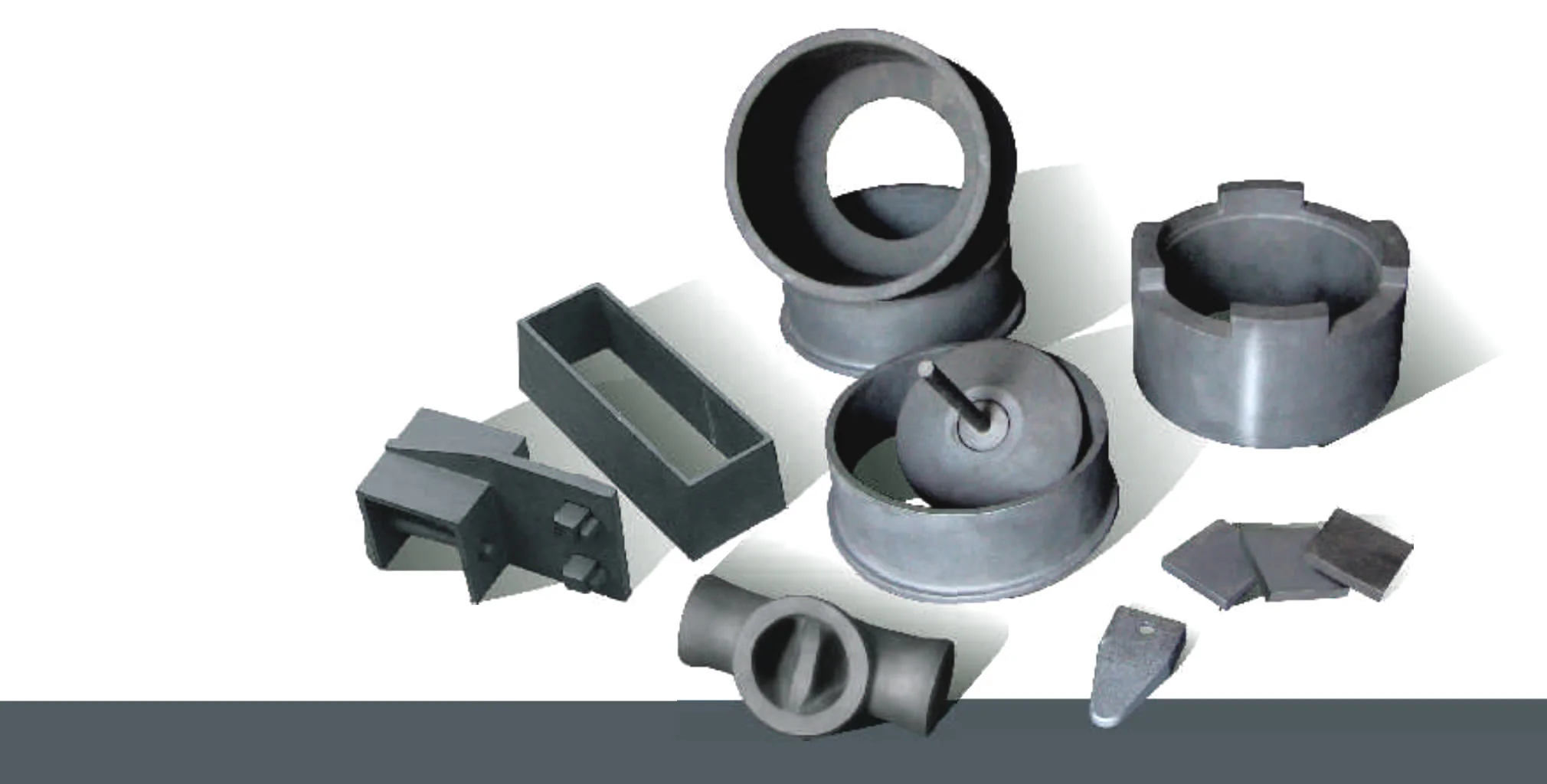

Silicon carbide alloy ceramic pipe elbows are designed for the harshest flow conditions in industrial pipeline systems. These elbows consist of a steel outer shell combined with an inner lining of silicon carbide-based ceramic alloy, delivering superior protection against abrasion, corrosion, high temperatures, and mechanical impact.

The ceramic alloy layer, typically bonded or cast inside the elbow, provides a high-hardness surface (Mohs hardness ~9), outperforming conventional metal and alumina-lined options. Its resistance to chemical attack and thermal cycling makes it particularly suitable for dynamic flow environments with aggressive or high-velocity materials.

These ceramic elbows are available in a wide range of sizes, angles (e.g. 45°, 90°), and connection types (flanged, welded, or grooved), and can be custom-manufactured to meet specific pipeline configurations.

By utilizing silicon carbide alloy ceramic pipe elbows, industries benefit from reduced maintenance, longer operating cycles, and enhanced pipeline reliability, even in the most demanding environments.