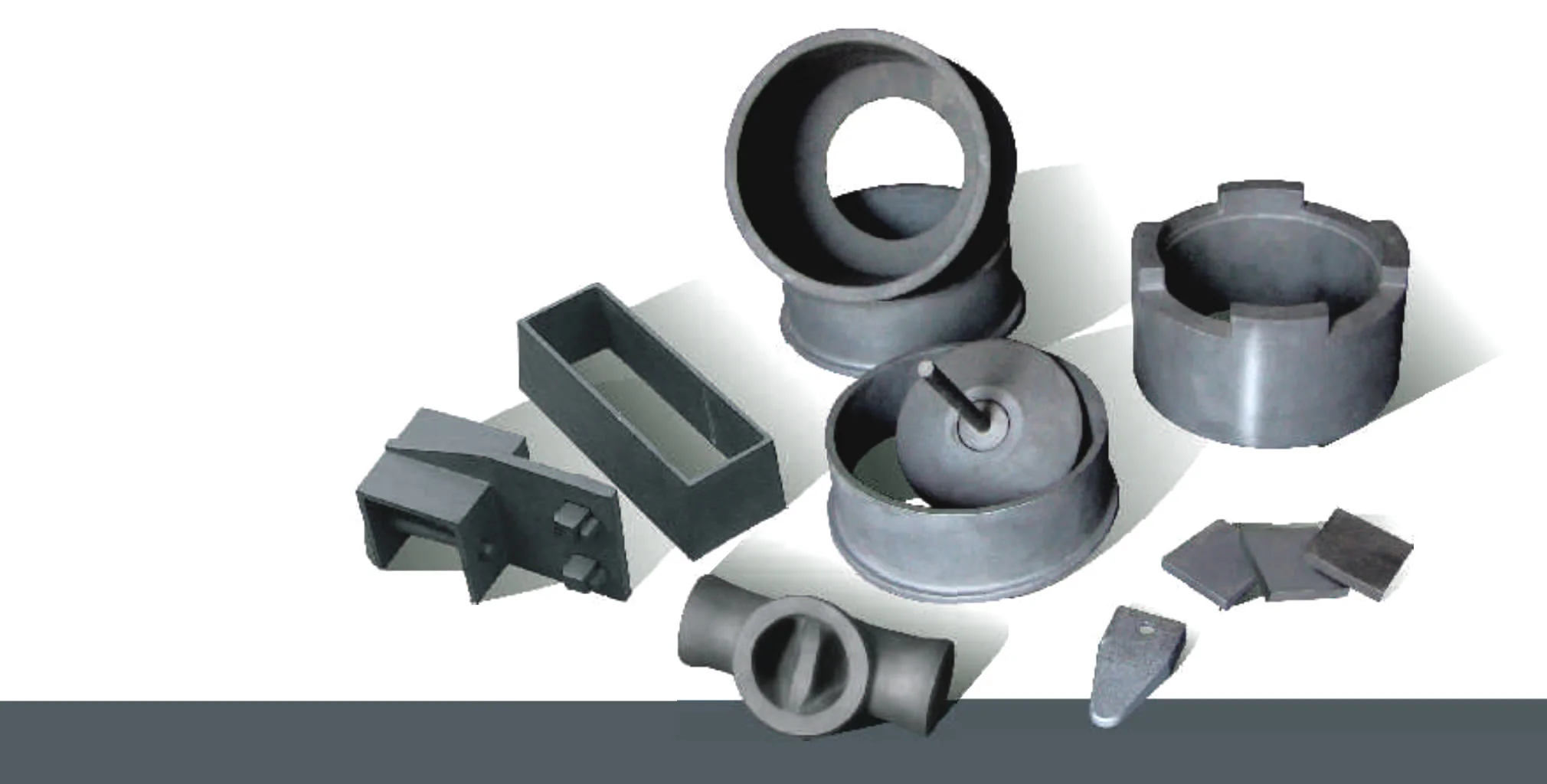

SiC swirl nozzles offer superior wear, corrosion, and thermal resistance, delivering efficient atomization for gas scrubbing, flue gas desulfurization, and chemical sprays.

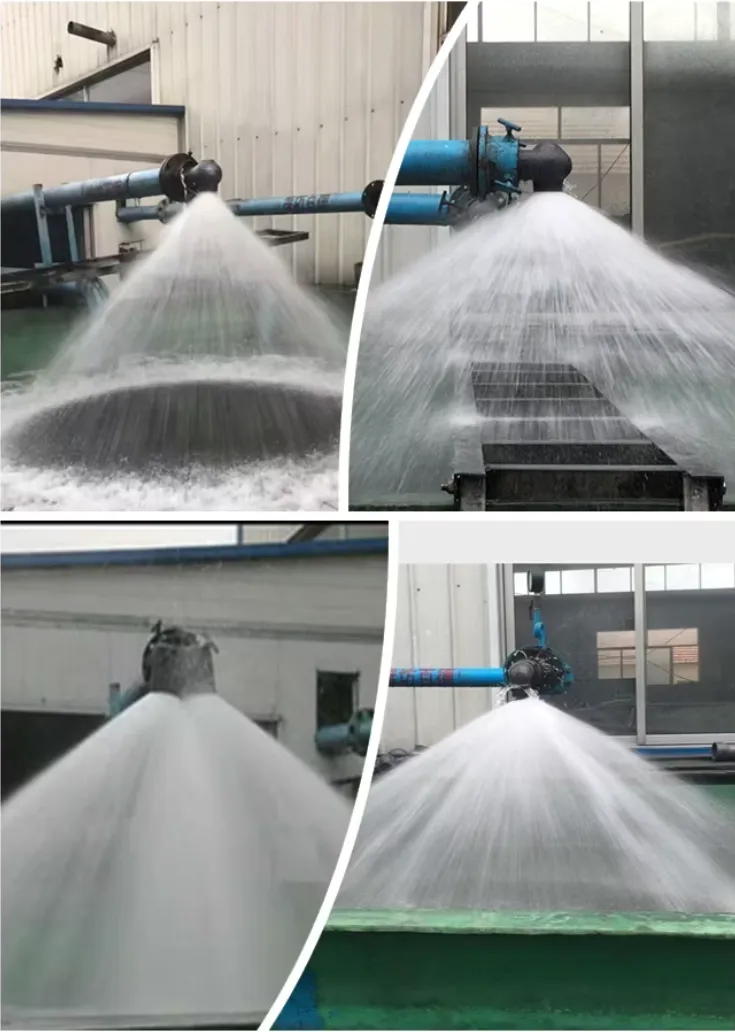

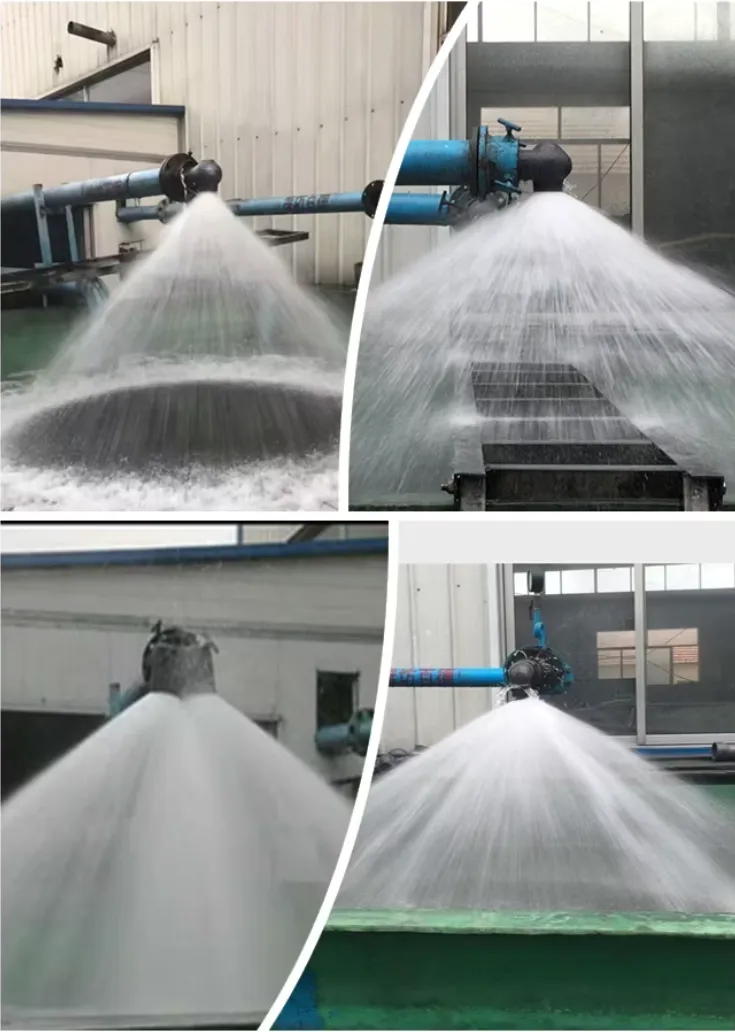

SiC swirl nozzles (also called silicon carbide spiral or vortex nozzles) are made from high-purity reaction bonded silicon carbide (SiC) and are designed to atomize liquids into fine droplets under high-pressure or turbulent gas flow conditions. Their unique spiral internal structure induces a vortex effect, producing a wide spray angle and fine mist distribution ideal for gas-liquid reactions.

Engineered for extreme conditions, SiC swirl nozzles exhibit exceptional hardness, corrosion resistance, and thermal stability, making them highly effective in flue gas desulfurization (FGD), dust control, chemical absorption, and cooling towers.

SiC swirl nozzles are available in various threaded or flanged connections, spray angles (typically 60°, 90°, 120°), and flow rates to suit specific system requirements. Their ability to withstand extreme abrasion and corrosion ensures uninterrupted performance and reduces maintenance frequency.