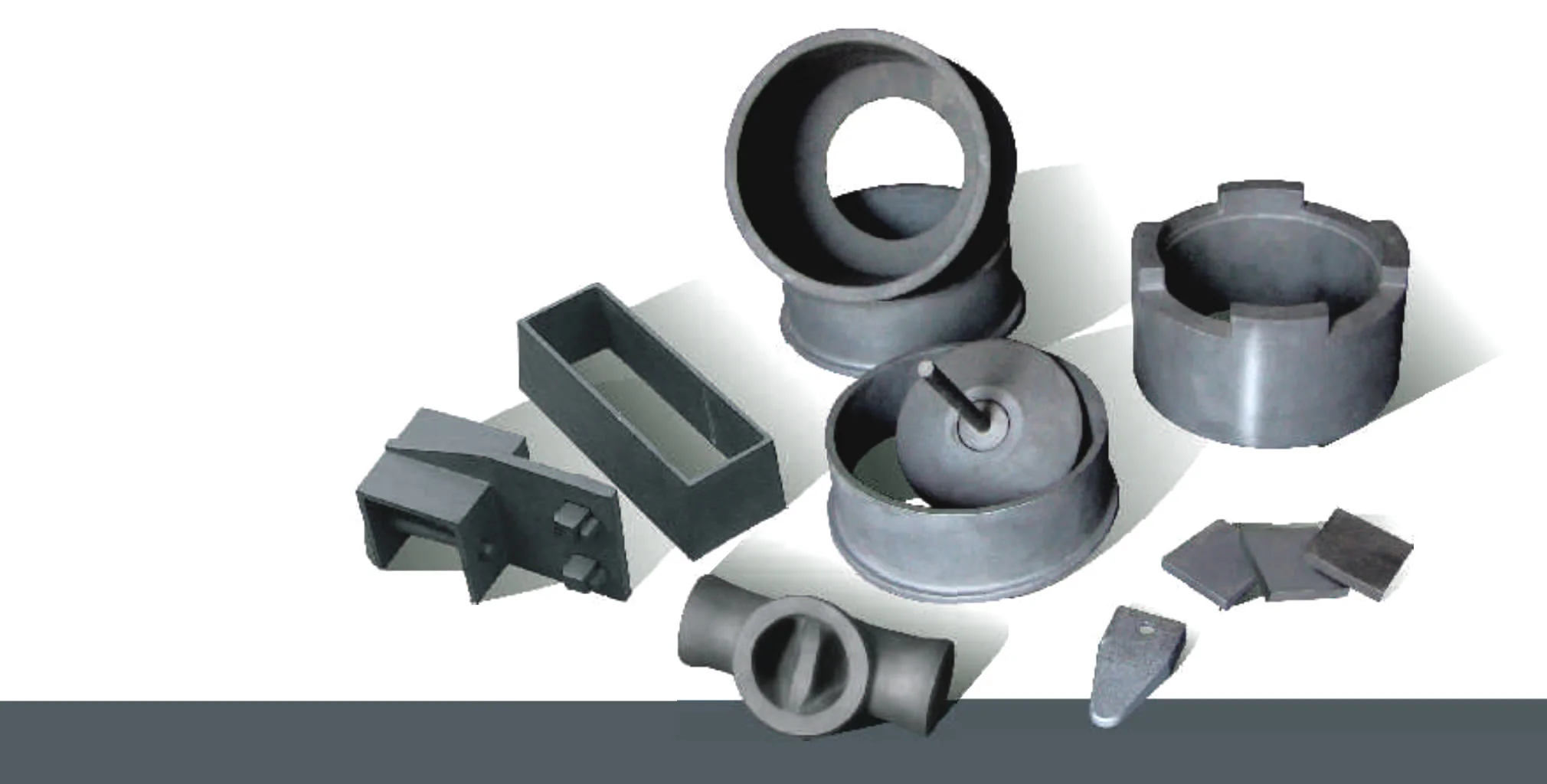

Replaceable Silicon Carbide Liners for Cyclone & Hydrocyclone

Advanced Silicon Carbide Liners Designed For Easy Replacement And Long-term Wear Resistance In Cyclone And Hydrocyclone Separation Systems.

Replaceable silicon carbide cyclone and hydrocyclone liners offer extreme wear, corrosion, and thermal resistance—ideal for mining, processing, and slurry separation systems.

Replaceable Silicon Carbide Liners for Cyclone & Hydrocyclone

Advanced Silicon Carbide Liners Designed For Easy Replacement And Long-term Wear Resistance In Cyclone And Hydrocyclone Separation Systems.

Replaceable silicon carbide cyclone and hydrocyclone liners offer extreme wear, corrosion, and thermal resistance—ideal for mining, processing, and slurry separation systems.