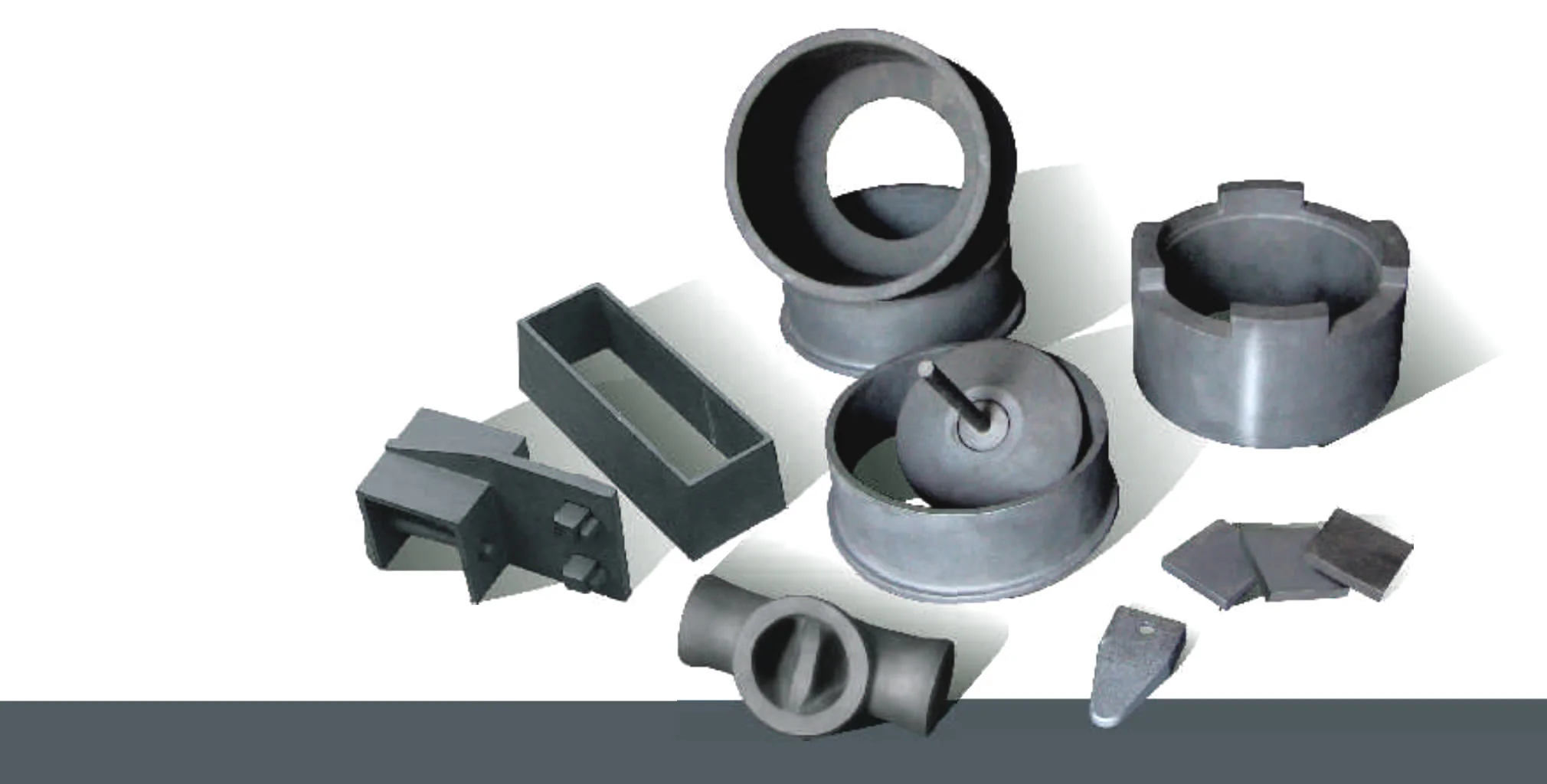

Durable SiC refractory bricks for kilns, furnaces, and high-wear zones, offering superior thermal conductivity and corrosion resistance.

Silicon carbide bricks are high-performance refractory products designed for use in extremely high-temperature and chemically aggressive environments. Composed of high-purity silicon carbide (SiC), these bricks are used to line industrial furnaces, kilns, incinerators, and reactors in processes where traditional refractory materials fail to perform.

SISIC bricks

Available in various compositions such as Oxide Bonded SiC (OBSiC), Nitride Bonded SiC (NBSiC), and Recrystallized SiC (RSiC), these bricks deliver exceptional abrasion resistance, thermal conductivity, and corrosion resistance.

Sunny Steel offers custom machining and precise sizing to meet unique furnace geometries and wear zone designs. Each brick is engineered for long service life, minimal maintenance, and enhanced process efficiency under high-load, corrosive, or high-flux thermal conditions.

Silicon carbide bricks have a high thermal conductivity, good wear resistance, thermal shock resistance, and corrosion resistance. Therefore, silicon carbide bricks have a wide range of industrial applications. They can be used for the lining of steel ladles in metallurgy, nozzles, plugs, the bottom and belly of blast furnaces, and water-cooled sliding rails in heating furnaces; distillation apparatus, rectification tower trays, side walls of electrolytic cells, and crucibles for melting metals in non-ferrous metal smelting; roof boards and flame retardant materials in kilns in the silicate industry; oil and gas generators, and organic waste incinerators in the chemical industry; crucibles for high-tech ceramics, linings for aluminum electrolytic cells, molten aluminum ducts, and kiln furniture for ceramic kilns, the lower part of large and medium-sized blast furnaces, furnace waist and belly, linings for aluminum refining furnaces, and linings for zinc distillation pots, etc.

(SiC) bricks’ physical and chemical indicators

| Item |

Bonding Type |

| Clay |

Mullite |

SiO2 |

Si3N4 |

Sialon |

β-SiC |

R-SiC |

Siliconizing Reaction |

| SiC % |

>85 |

>70 |

≥90 |

≥72 |

≥71 |

≥94 |

≥99 |

≥80 |

| Si3N4 % |

/ |

/ |

/ |

≥20 |

/ |

/ |

/ |

/ |

| Al2O3 % |

/ |

/ |

/ |

/ |

≥5 |

/ |

/ |

/ |

| Si % |

/ |

/ |

/ |

/ |

≥5.5 (N) |

/ |

/ |

12~18 |

| Bulk Density (g/cm3) |

2.5~2.6 |

2.55~2.65 |

2.6~2.7 |

≥2.65 |

≥2.65 |

≥2.63 |

≥2.65 |

≥3.0 |

| Apparent Porosity % |

≤20 |

≤16 |

≤15 |

≤16 |

≤16 |

≤17 |

≤15 |

≤0.5 |

| Flexural Strength at RT (MPa) |

≥20 |

≥25 |

≥25 |

≥45 |

≥45 |

≥30 |

≥90 |

≥220 |

| Flexural Strength at 1400°C (MPa) |

/ |

/ |

/ |

≥45 |

≥45 |

≥30 |

≥90 |

≥240 |

| Cold Crushing Strength (MPa) |

≥100 |

≥100 |

≥120 |

≥160 |

≥150 |

≥140 |

≥300 |

≥800 |