Silicon Carbide Batts RBSIC / SiSiC

High Strength Kiln Shelves

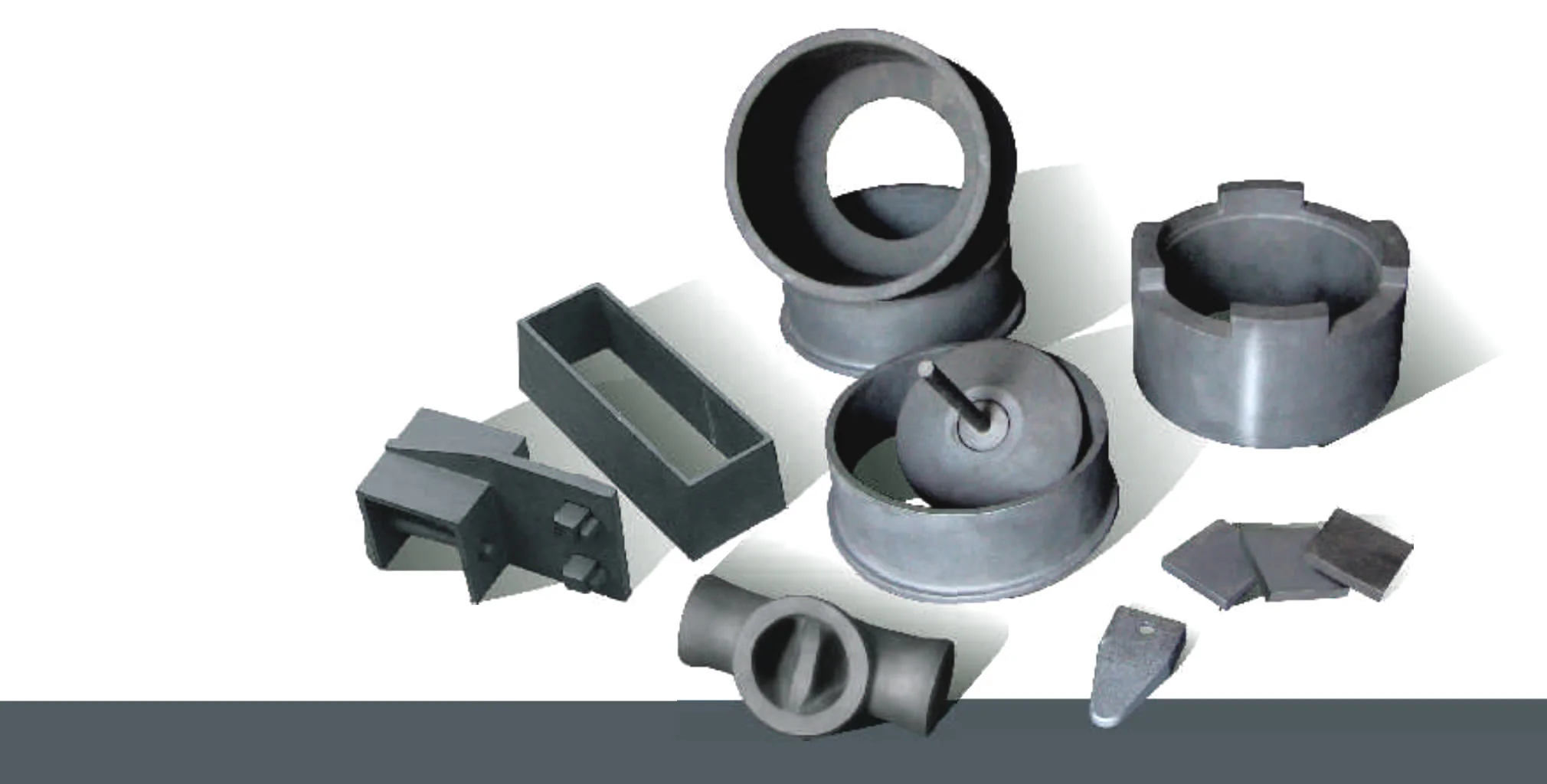

Advanced reaction bonded sic batts offer superior load-bearing, thermal shock resistance, and flatness for high-temperature kiln operations.

Silicon Carbide Batts RBSIC / SiSiC

High Strength Kiln Shelves

Advanced reaction bonded sic batts offer superior load-bearing, thermal shock resistance, and flatness for high-temperature kiln operations.