SiSiC Desulfurization Spray Nozzle

High Wear & Corrosion Resistant

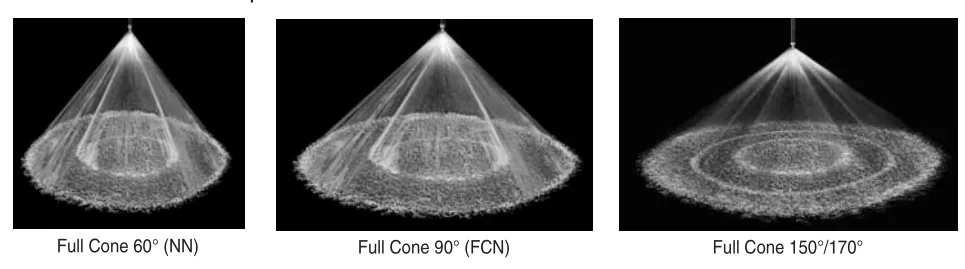

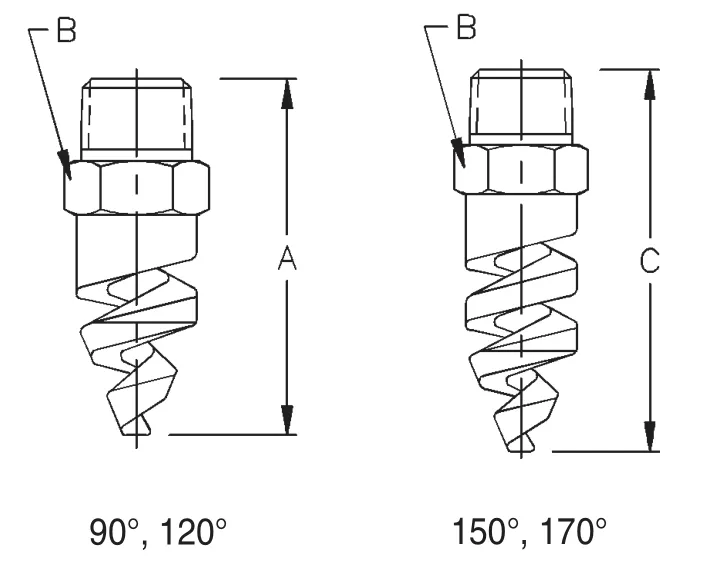

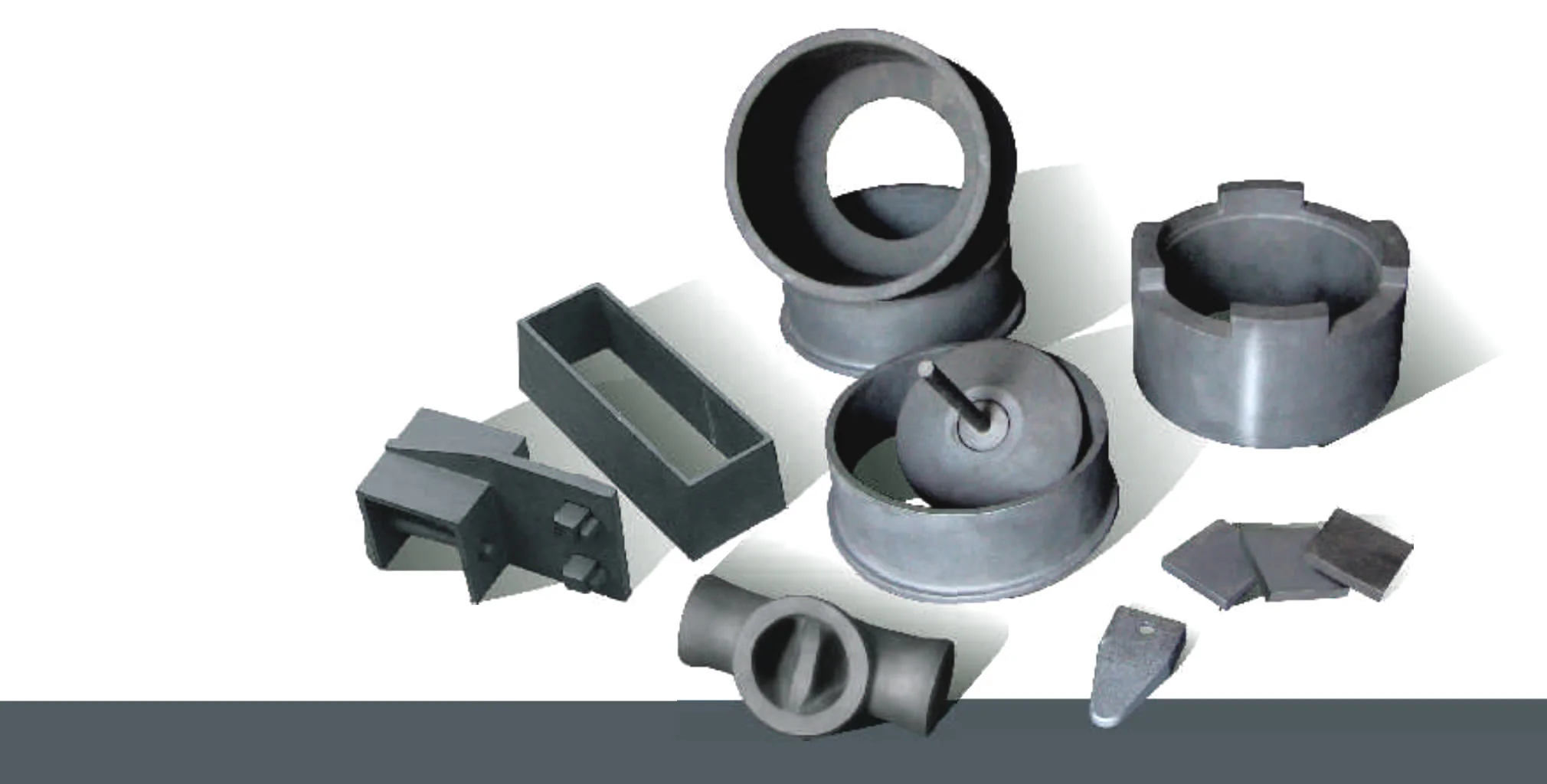

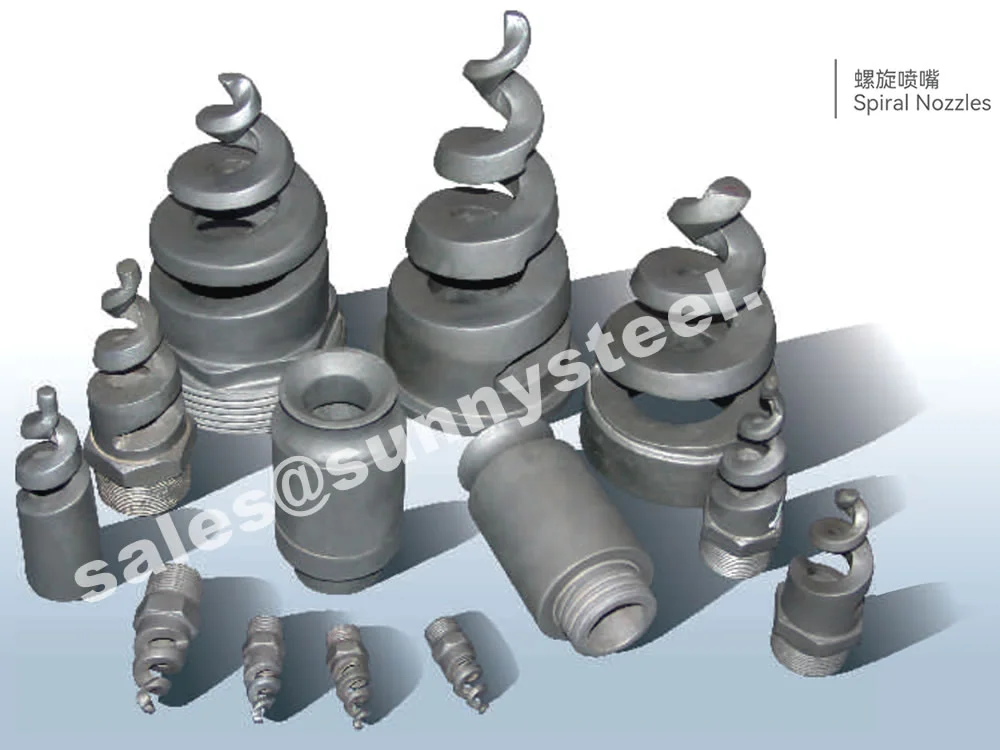

Sisic desulfurization spray nozzles deliver exceptional wear and corrosion resistance, ideal for flue gas desulfurization (fgd) systems in coal-fired power plants and industrial boilers.

SiSiC Desulfurization Spray Nozzle

High Wear & Corrosion Resistant

Sisic desulfurization spray nozzles deliver exceptional wear and corrosion resistance, ideal for flue gas desulfurization (fgd) systems in coal-fired power plants and industrial boilers.