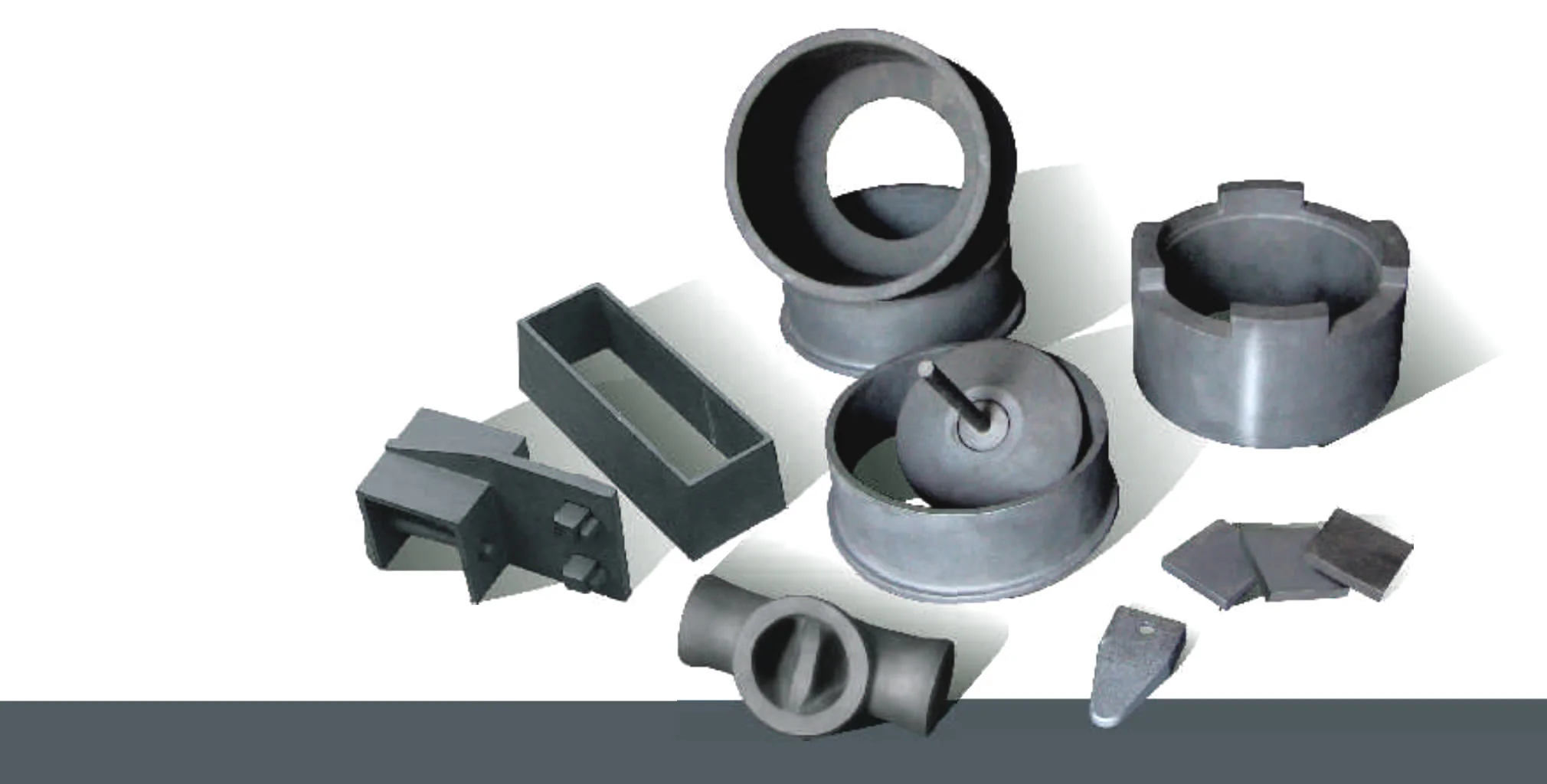

Silicon Carbide Crucibles

High Strength & Thermal Shock Resistant Melting Pots

Silicon carbide crucibles deliver excellent heat conductivity, strength, and corrosion resistance—ideal for melting non-ferrous metals, alloys, and glass at high temperatures.

Silicon Carbide Crucibles

High Strength & Thermal Shock Resistant Melting Pots

Silicon carbide crucibles deliver excellent heat conductivity, strength, and corrosion resistance—ideal for melting non-ferrous metals, alloys, and glass at high temperatures.