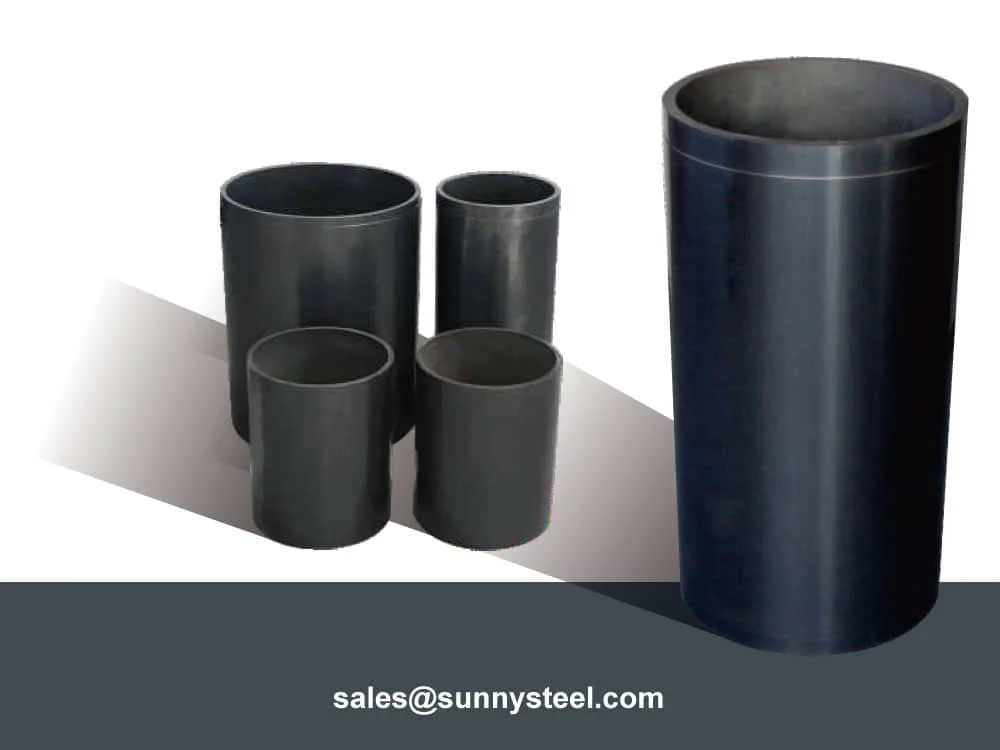

SISIC Sand Mill Inner Barrel

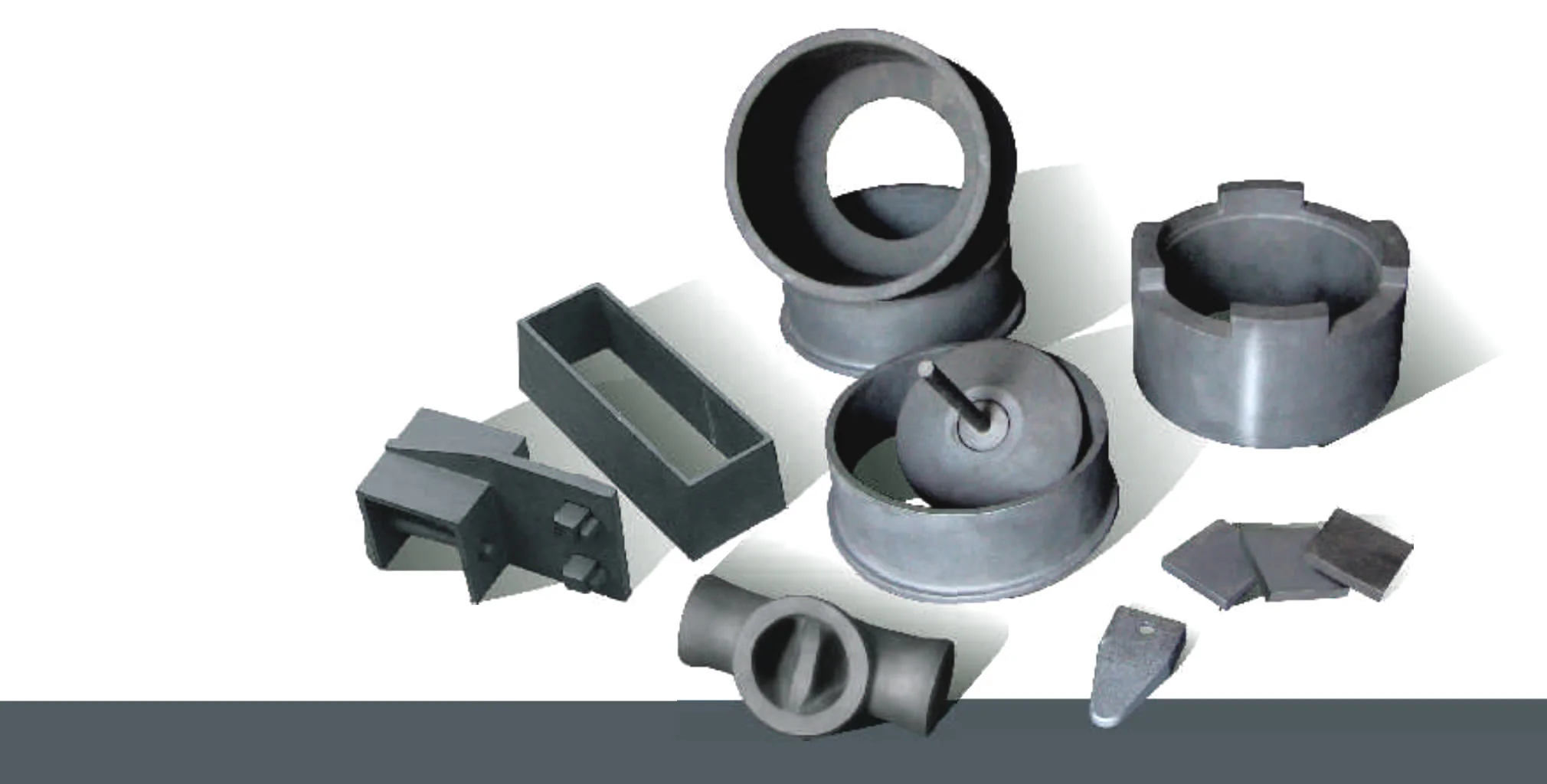

Ultra-hard Wear-resistant Liner

Sisic sand mill inner barrels offer unmatched wear and corrosion resistance, ensuring stable performance and extended service life in ultra-fine grinding and dispersion systems.

SISIC Sand Mill Inner Barrel

Ultra-hard Wear-resistant Liner

Sisic sand mill inner barrels offer unmatched wear and corrosion resistance, ensuring stable performance and extended service life in ultra-fine grinding and dispersion systems.