SISIC Kiln Tubes

High Strength Tubes For High-temperature Kilns

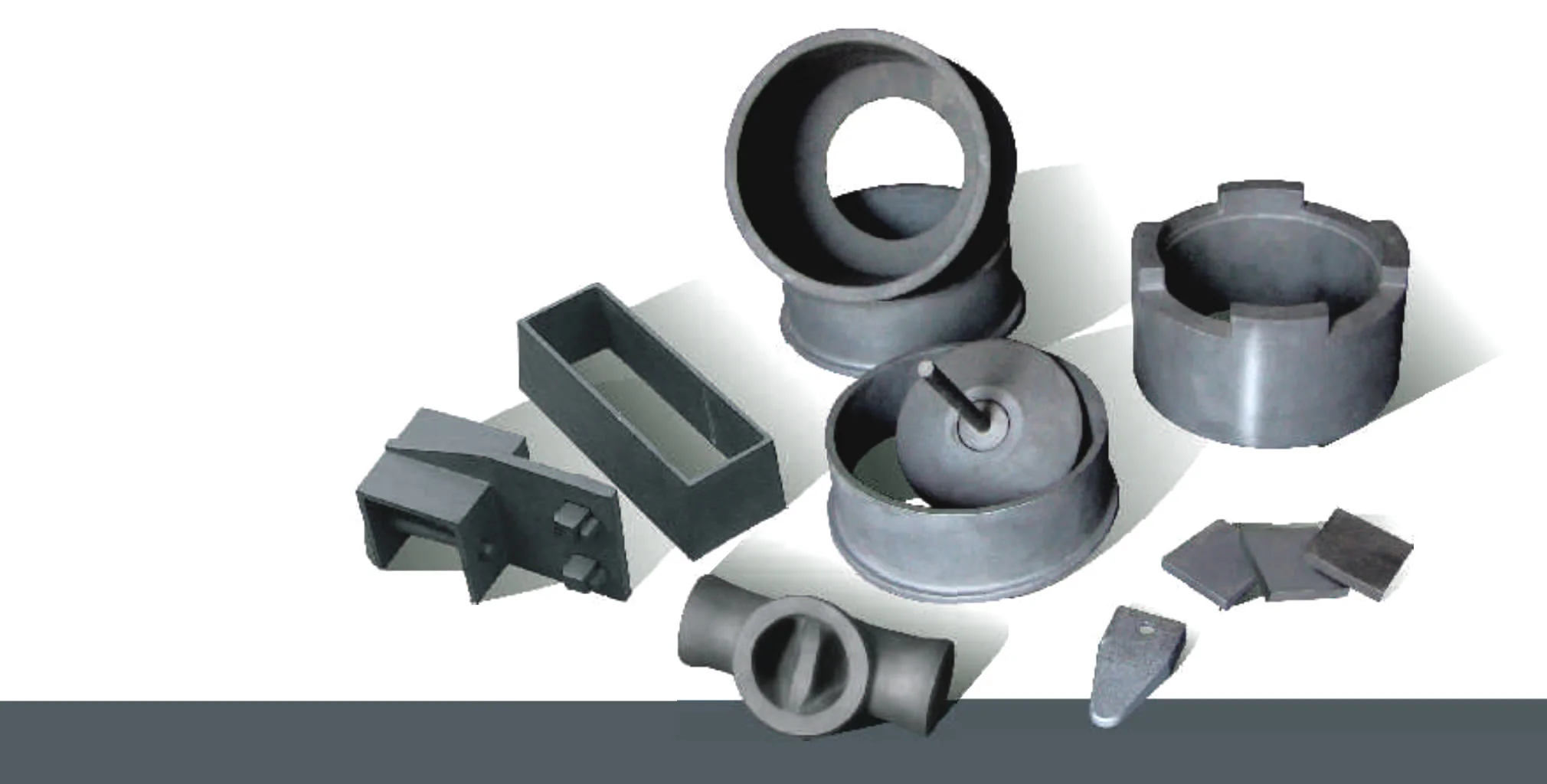

Sisic kiln tubes provide excellent strength, thermal shock resistance, and oxidation stability—ideal for roller kilns and thermal processing of ceramics, powders, and catalysts.

SISIC Kiln Tubes

High Strength Tubes For High-temperature Kilns

Sisic kiln tubes provide excellent strength, thermal shock resistance, and oxidation stability—ideal for roller kilns and thermal processing of ceramics, powders, and catalysts.