High Performance Wear-resistant Elbow

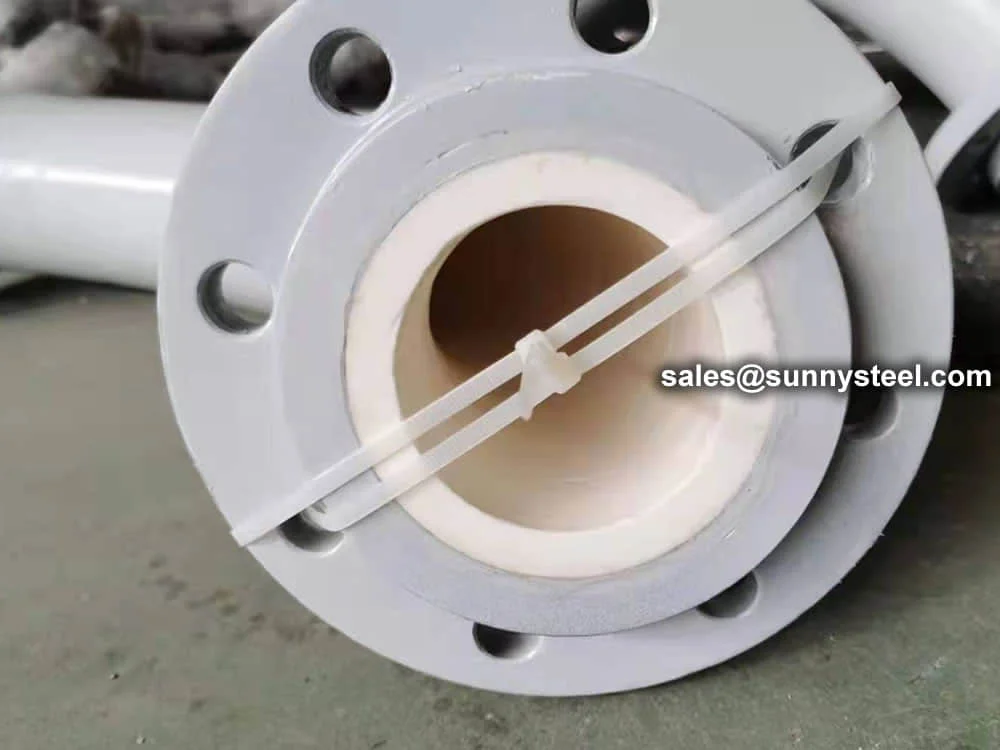

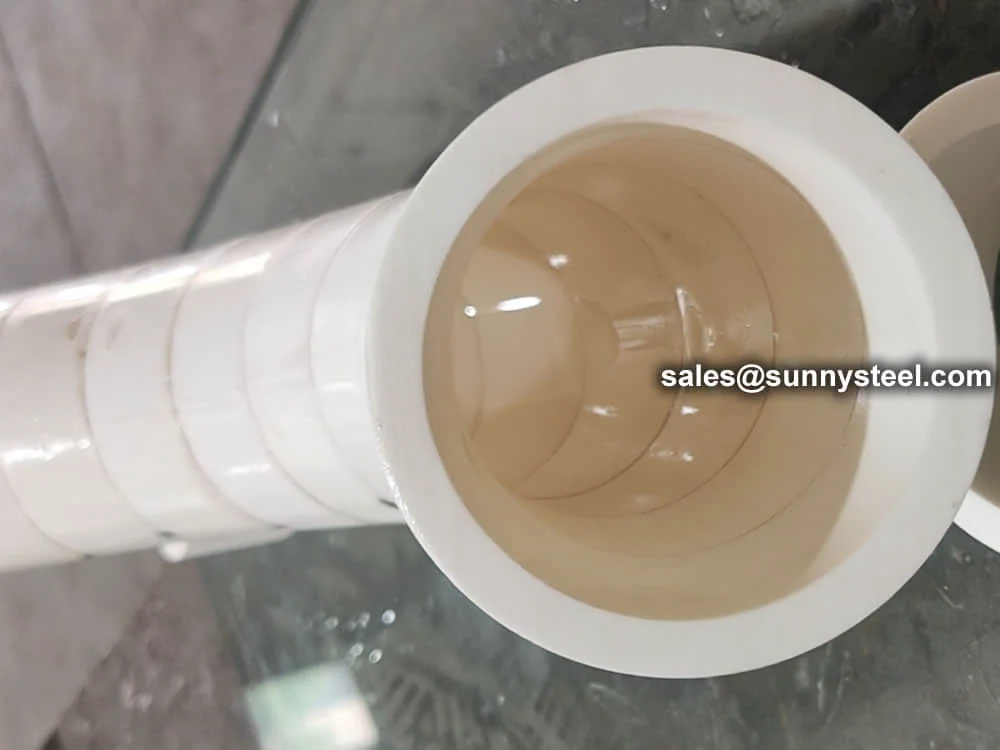

Ceramic sleeve lined pipe bends provide superior protection against abrasion, corrosion, and high-impact wear in curved pipeline sections, ensuring extended service life and reduced maintenance.

High Performance Wear-resistant Elbow

Ceramic sleeve lined pipe bends provide superior protection against abrasion, corrosion, and high-impact wear in curved pipeline sections, ensuring extended service life and reduced maintenance.

Ceramic sleeve lined pipe bends are engineered for extreme wear resistance and longevity in high-abrasion and high-temperature flow systems. Featuring alumina ceramic liners encased in carbon steel, these bends reduce system downtime and maintenance costs in harsh industrial environments.

Alumina ceramic liners (Mohs 9) resist erosion from ash, slurry, and particulate flows.

Ideal for acidic, alkaline, or chemically reactive pipelines.

Withstands up to 800°C, suitable for flue gas, coal powder, and hot slurry systems.

5–10× longer lifespan than conventional steel bends, reducing replacement frequency.

Carbon steel housing provides strength and impact resistance in dynamic systems.

Available in 30°, 45°, 60°, 90°, or long-radius bends with flanged or welded ends.

| Ceramic Lining | Alumina (92%–95%) |

|---|---|

| Steel Shell | Carbon Steel / Q235 / Q345 |

| Liner Hardness | Mohs 9 |

| Elbow Angles | 30°, 45°, 60°, 90°, Custom |

| Pipe Size Range | DN50 – DN800 |

| Max Operating Temperature | Up to 800°C |

| Max Pressure | ≤ 2.5 MPa |

| Connection Types | Flanged / Welded / Grooved |

Sunny Steel offers precision-engineered ceramic sleeve lined pipe bends tailored to your pipeline's temperature, media, and flow requirements. Our elbows are widely used in power generation, mining, cement, and chemical industries to enhance pipeline reliability and reduce lifecycle costs.

Ceramic sleeve lined pipe tees provide outstanding...

Ceramic sleeves lined pipes combine the strength o...

Wear resistant ceramic lined pipe bends provide un...

Alumina ceramic sleeve lined pipe bends offer outs...