Ultra-durable Pipeline For Abrasive Media

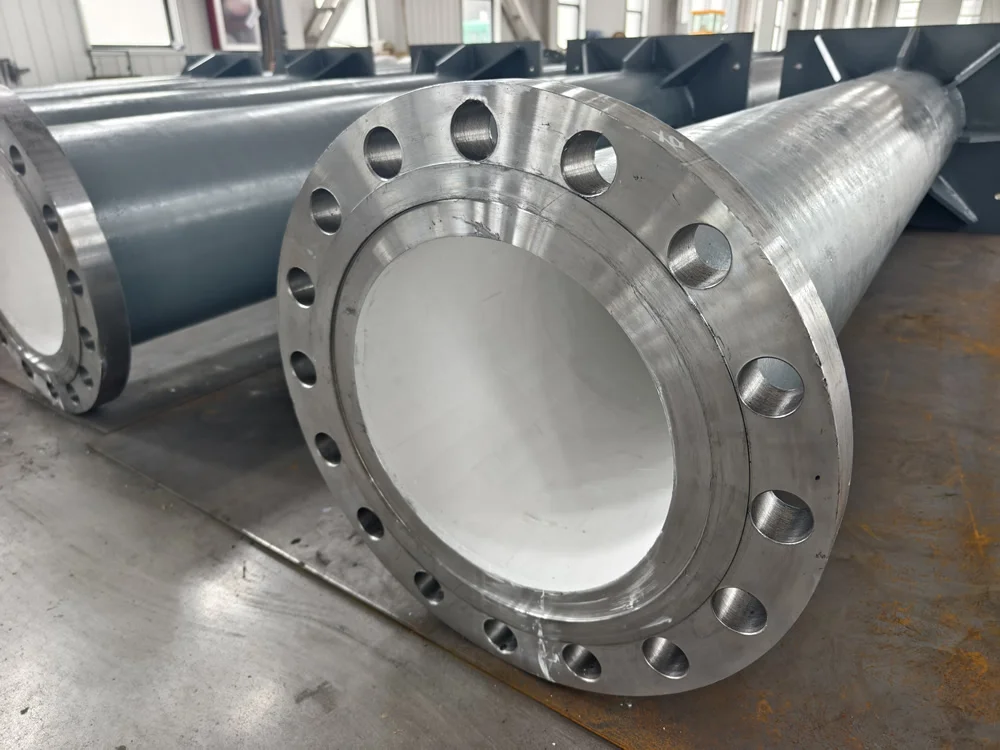

This composite steel pipe with ceramic ring lining provides extreme wear resistance, structural strength, and a long service life in high-abrasion flow systems such as ash, slurry, or sand transport.

Ultra-durable Pipeline For Abrasive Media

This composite steel pipe with ceramic ring lining provides extreme wear resistance, structural strength, and a long service life in high-abrasion flow systems such as ash, slurry, or sand transport.

Designed for extreme industrial conditions, our ceramic ring lined pipes integrate a robust carbon or alloy steel shell with high-purity alumina ceramic rings (Al₂O₃ ≥92–95%). Each ring is axially aligned and precisely bonded, forming a seamless, ultra-hard inner wall that resists abrasion, chemical attack, and high-velocity particle erosion.

This modular construction ensures consistent wear protection, facilitates segment replacement, and significantly extends service life compared to rubber, bare steel, or stainless steel alternatives. These pipes are ideal for handling ash, slurry, cement powder, or corrosive media in power, mining, cement, and chemical industries.

Mohs hardness up to 9 for maximum resistance to abrasion, corrosion, and heat.

Carbon or alloy steel provides structural strength and high-pressure capacity.

Precision-aligned ceramic rings enable uniform wear and easy segment replacement.

Minimizes flow turbulence, pressure drop, and material build-up.

Available in DN50–DN800+, with adjustable lengths and ring thicknesses.

Ash handling pipelines in thermal power stations.

Iron ore and coal slurry pipes in processing lines.

Pneumatic conveying of cement, lime, and powders.

Corrosive and acid-resistant media transport systems.

| Liner Material | Alumina Ceramic (Al₂O₃ ≥92%) |

|---|---|

| Outer Shell | Carbon Steel / Alloy Steel |

| Hardness | Mohs 9 |

| Working Temperature | Up to 800°C |

| Diameter Range | DN50 – DN800 (customizable) |

| Pressure Tolerance | ≤ 2.5 MPa |

| Ring Thickness | 6 mm – 25 mm |

| Connection Types | Flanged / Welded / Grooved |

| Ceramic Installation | Bonded / Shrink-fit alignment |

Sunny Steel offers custom engineering, production, and support for ceramic ring lined composite pipes. We provide tailored anti-wear solutions based on your material, flow conditions, and pressure requirements.

Ceramic lined wear resistant pipes provide outstan...