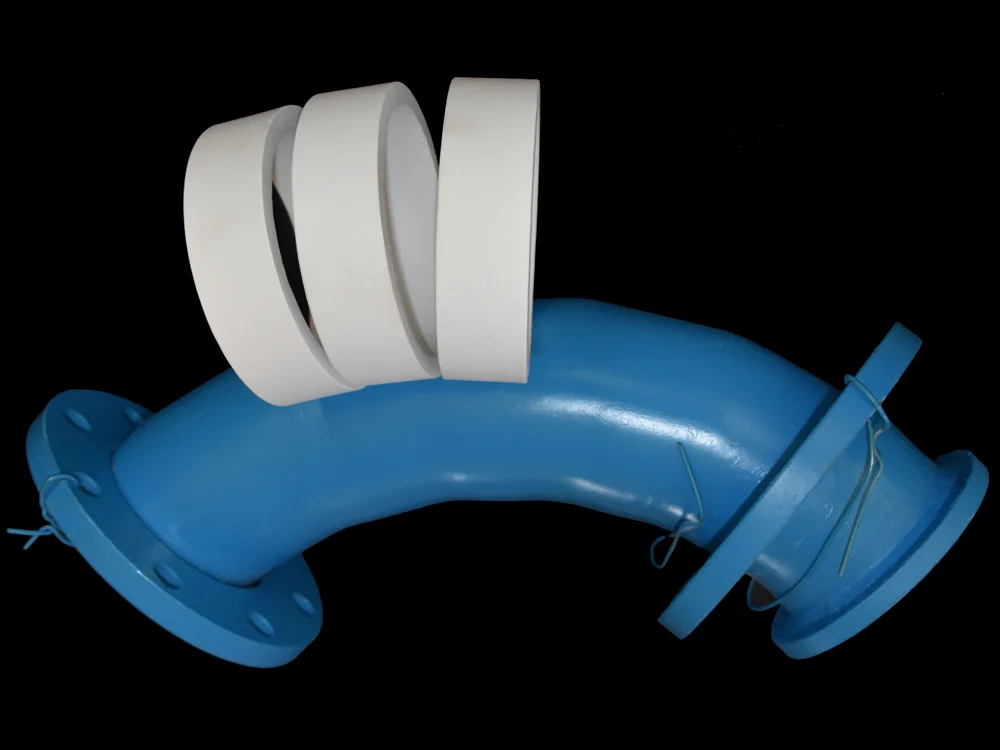

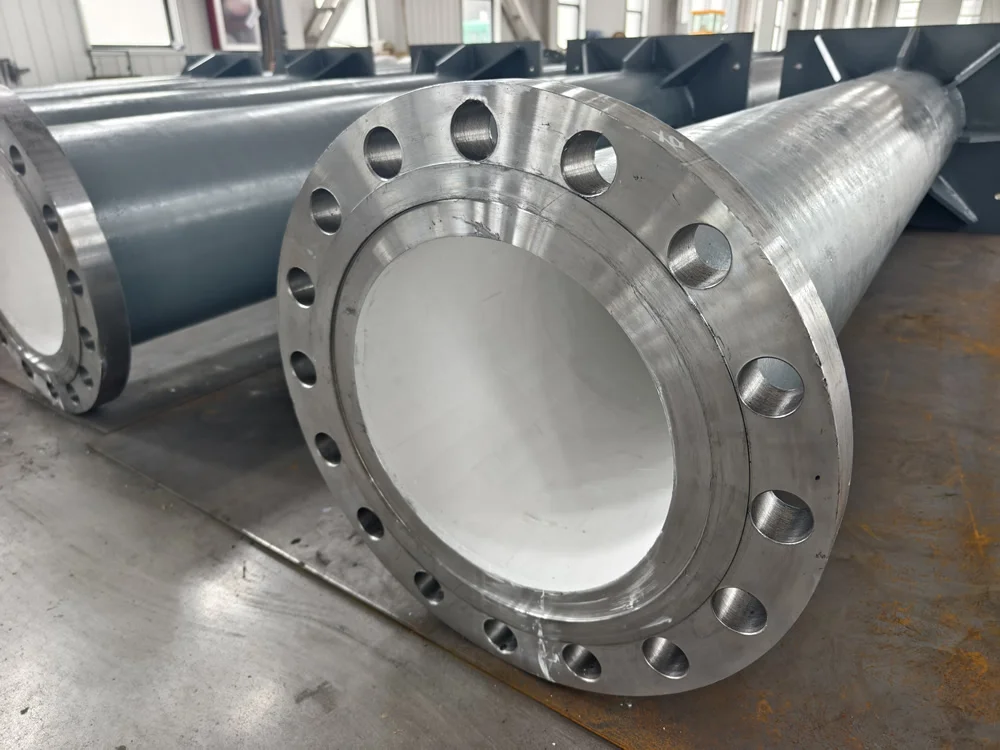

Wear-resistant lined bends and pipes for pneumatic conveying systems are engineered to handle abrasive and erosive media such as fly ash, cement, lime, and plastic granules. These components typically feature internal linings made of high-purity alumina ceramics or cast basalt, which significantly reduce internal wall erosion and turbulence at directional changes.

The steel outer shell provides structural strength and pressure resistance, while the optimized bend radius ensures smooth material flow with minimal energy loss. These lined pipelines are widely used in pneumatic transport systems across industries such as power generation, cement production, and chemical processing. They are available in a variety of diameters, bend angles (30°, 45°, 60°, 90°, or custom), and connection methods including flanged, grooved, or welded ends.

Their extended lifespan, low maintenance requirement, and consistent performance make them an ideal replacement for unlined or rubber-lined steel elbows in bulk material handling lines. Custom manufacturing ensures compatibility with existing pipeline systems, making these solutions efficient, cost-effective, and easy to integrate.