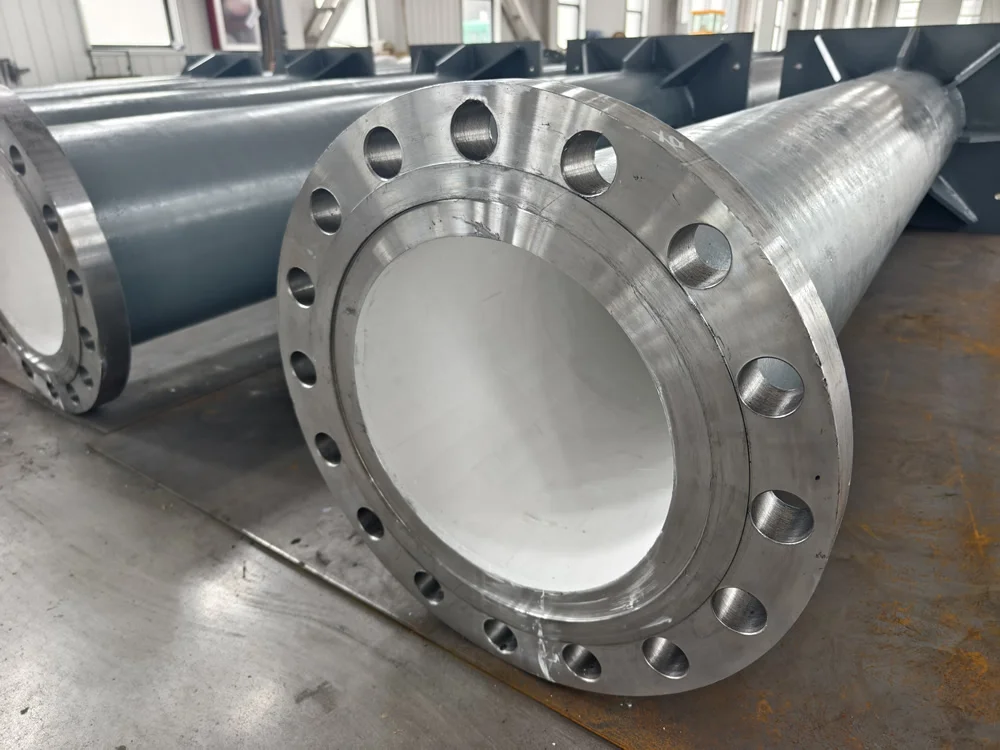

95% alumina ceramic lined steel pipe fittings are engineered to provide exceptional wear protection in high-abrasion and high-impact industrial environments. These fittings are constructed from carbon or alloy steel as the structural outer body, while the internal surfaces are lined with dense, high-hardness alumina ceramic tiles or tubes with an alumina content of at least 95%.

This combination significantly enhances resistance to abrasion, erosion, and chemical corrosion compared to unlined or rubber-lined metal fittings. The high alumina content ensures Mohs hardness over 9, making these pipe fittings ideal for conveying systems in industries such as mining, thermal power, cement, steel, and chemical processing.

These fittings include elbows, tees, reducers, and laterals, and are commonly used for transporting fly ash, coal powder, slurry, and mineral concentrates. They can be produced in various diameters and connection methods including flanged, welded, or quick coupling joints to suit different piping systems.

The use of 95% alumina ceramics ensures excellent performance under high-speed and high-load conveying conditions, prolonging pipeline service life and reducing maintenance costs.