Reinforced ceramic sleeve lined elbows are designed to withstand severe abrasive and erosive conditions in high-velocity conveying systems. The interior of the elbow features precision-engineered ceramic sleeves—typically alumina with a hardness exceeding Mohs 9—which offer superior resistance to wear from continuous flow of ash, slurry, and fine particulate matter.

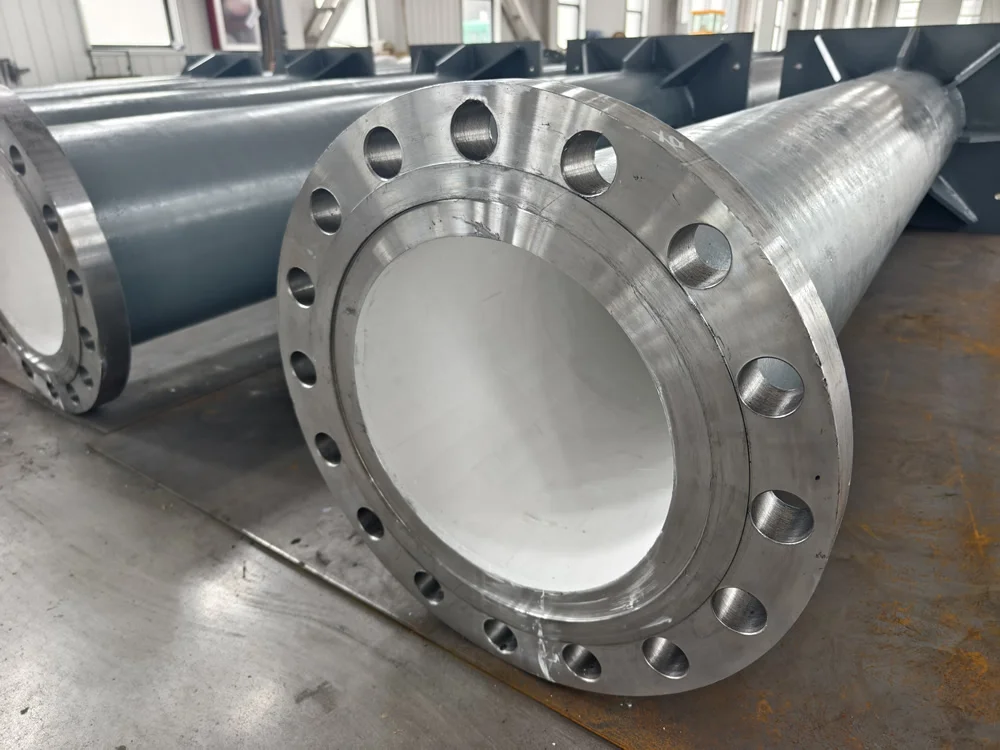

The external steel or alloy casing provides mechanical support, while the reinforcement structure absorbs stress from internal pressure and impact, ensuring structural integrity over prolonged operation. This dual-layer design is especially useful in high-wear industries like thermal power generation, cement plants, mining, metallurgy, and chemical processing.

These elbows are typically available in 45°, 60°, 90°, and custom angles with sizes ranging from DN50 to DN800. They are compatible with various pipeline systems via flange, welding, or clamp connections. Key applications include fly ash pneumatic transport, bottom ash disposal lines, and lime slurry distribution.

The reinforced ceramic sleeve lined elbow significantly reduces downtime and maintenance frequency, offering a cost-effective solution to combat pipeline wear and leakage.