For Enhanced Abrasion Resistance

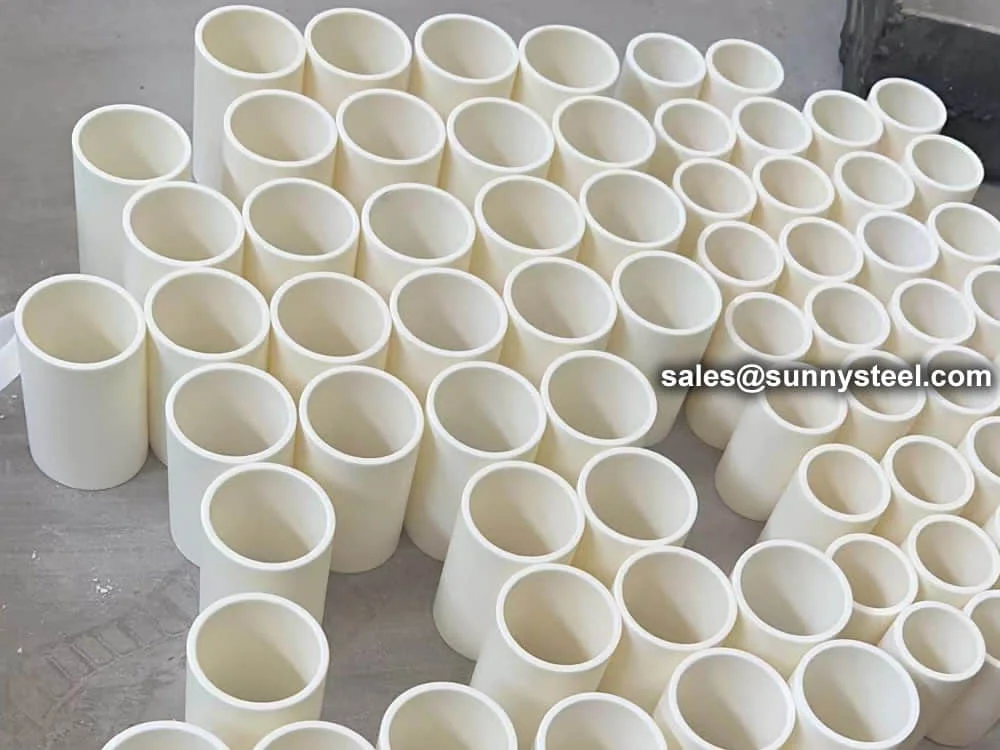

Alumina ceramic cyclone liner tubes offer superior abrasion resistance, extending cyclone service life in abrasive industrial environments.

For Enhanced Abrasion Resistance

Alumina ceramic cyclone liner tubes offer superior abrasion resistance, extending cyclone service life in abrasive industrial environments.

| Material | Unit | 95% Al2O3 | 96% Al2O3 | 99% Al2O3 | 99.5% Al2O3 | 99.8% Al2O3 |

|---|---|---|---|---|---|---|

| Purity | % | 95 | 96 | 99 | 99.5 | 99.8 |

| Color | --- | White/Pink | White | Ivory | Ivory | Ivory |

| Density | g/cm³ | 3.65 | 3.72 | 3.85 | 3.90 | 3.92 |

| Water Absorption | % | 0 | 0 | 0 | 0 | 0 |

| Moh's Hardness | --- | 9 | 9 | 9 | 9 | 9 |

| HV Hardness | --- | >1300 | >1300 | 1700 | 1750 | 1800 |

| Flexural Strength @25°C | MPa | 300 | 300 | 330 | 375 | 390 |

| Fracture Toughness | MPa·m1/2 | 3~4 | 3~4 | 3~4 | 4 | 4 |

| Compressive Strength (25°C) | MPa | 2200 | 2200 | 2350 | 2450 | 2500 |

| Thermal Conductivity @25°C | W/m·K | 18–22 | ≥24 | 27 | 29 | 32 |

| Thermal Expansion Coefficient (25–1000°C) | 10-6/°C | 8 | 8 | 8 | 8 | 8 |

| Thermal Shock Resistance | ΔT (°C) | 220 | 220 | 180–200 | 180–200 | 180–200 |

| Max. Working Temperature | °C | 1500 | 1500 | 1700 | 1750 | 1750 |

| Dielectric Strength | kV/mm | 16 | 17.2 | 20 | 22 | 22 |

| Electrical Resistivity @25°C | Ω·cm | 1014 | 1014 | 1014 | 1014 | 1014 |

| Dielectric Constant @1MHz | --- | 9 | 9 | 9.7 | 9.7 | 9.8 |

| Dielectric Loss (Tan δ) @1MHz | --- | 0.0004 | 0.0002 | 0.0002 | 0.0001 | 0.0001 |

Compare physical, thermal, and electrical properties across various purity levels of alumina ceramic (Al2O3).

| Parameter | Details |

|---|---|

| Material Options | Alumina (40%–99.8%), Zirconia, Silicon Carbide, Silicon Nitride |

| Forming Methods | Extrusion, Dry Pressed, Hot Pressed, CIM, ISO Pressed |

| Dimensional Capability | Min. ID: 1mm; Max. OD: 800mm |

| Dimensional Tolerance | OD ±0.005mm, ID ±0.01mm, Length ±0.001mm |

| Surface Treatment | Polished, Glazed, or Metalized |

| Secondary Processing | CNC machining, lapping, threading, drilling, grinding, laser cutting |

Standard manufacturing capabilities and tolerances for ceramic tube products.

Aluminum oxide (al₂o₃) ceramic provides outstandin...

Wear-resistant alumina ceramic rings offer excelle...

Alumina ceramic lined components provide superior ...

95% al₂o₃ ceramic sleeves provide exceptional hard...

Alumina ceramic insulation pipes provide superior ...