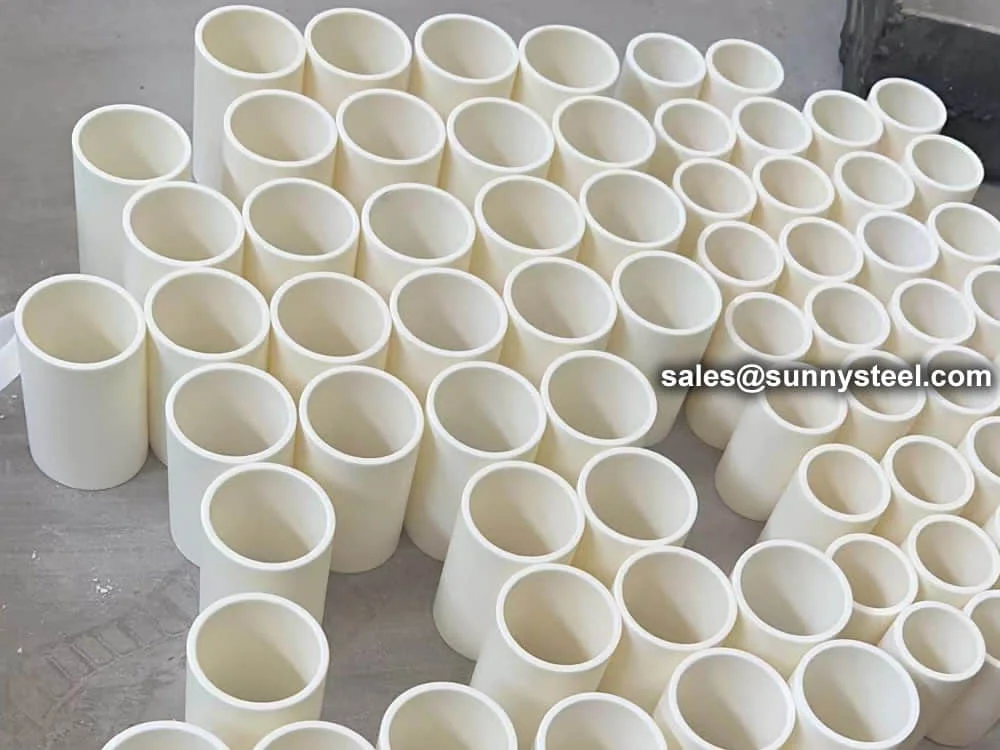

High-purity Alumina Ceramic Tubes For Insulation In High-temperature And High-voltage Environments

Alumina ceramic insulation pipes provide superior thermal and electrical insulation for applications in high-temperature, corrosive, and high-voltage environments.

High-purity Alumina Ceramic Tubes For Insulation In High-temperature And High-voltage Environments

Alumina ceramic insulation pipes provide superior thermal and electrical insulation for applications in high-temperature, corrosive, and high-voltage environments.

| Material | Unit | 95% Al2O3 | 96% Al2O3 | 99% Al2O3 | 99.5% Al2O3 | 99.8% Al2O3 |

|---|---|---|---|---|---|---|

| Purity | % | 95 | 96 | 99 | 99.5 | 99.8 |

| Color | --- | White/Pink | White | Ivory | Ivory | Ivory |

| Density | g/cm³ | 3.65 | 3.72 | 3.85 | 3.90 | 3.92 |

| Water Absorption | % | 0 | 0 | 0 | 0 | 0 |

| Moh's Hardness | --- | 9 | 9 | 9 | 9 | 9 |

| HV Hardness | --- | >1300 | >1300 | 1700 | 1750 | 1800 |

| Flexural Strength @25°C | MPa | 300 | 300 | 330 | 375 | 390 |

| Fracture Toughness | MPa·m1/2 | 3~4 | 3~4 | 3~4 | 4 | 4 |

| Compressive Strength (25°C) | MPa | 2200 | 2200 | 2350 | 2450 | 2500 |

| Thermal Conductivity @25°C | W/m·K | 18–22 | ≥24 | 27 | 29 | 32 |

| Thermal Expansion Coefficient (25–1000°C) | 10-6/°C | 8 | 8 | 8 | 8 | 8 |

| Thermal Shock Resistance | ΔT (°C) | 220 | 220 | 180–200 | 180–200 | 180–200 |

| Max. Working Temperature | °C | 1500 | 1500 | 1700 | 1750 | 1750 |

| Dielectric Strength | kV/mm | 16 | 17.2 | 20 | 22 | 22 |

| Electrical Resistivity @25°C | Ω·cm | 1014 | 1014 | 1014 | 1014 | 1014 |

| Dielectric Constant @1MHz | --- | 9 | 9 | 9.7 | 9.7 | 9.8 |

| Dielectric Loss (Tan δ) @1MHz | --- | 0.0004 | 0.0002 | 0.0002 | 0.0001 | 0.0001 |

Compare physical, thermal, and electrical properties across various purity levels of alumina ceramic (Al2O3).

| Parameter | Details |

|---|---|

| Material Options | Alumina (40%–99.8%), Zirconia, Silicon Carbide, Silicon Nitride |

| Forming Methods | Extrusion, Dry Pressed, Hot Pressed, CIM, ISO Pressed |

| Dimensional Capability | Min. ID: 1mm; Max. OD: 800mm |

| Dimensional Tolerance | OD ±0.005mm, ID ±0.01mm, Length ±0.001mm |

| Surface Treatment | Polished, Glazed, or Metalized |

| Secondary Processing | CNC machining, lapping, threading, drilling, grinding, laser cutting |

Standard manufacturing capabilities and tolerances for ceramic tube products.

Aluminum oxide (al₂o₃) ceramic provides outstandin...

Alumina ceramic cyclone liner tubes offer superior...

Wear-resistant alumina ceramic rings offer excelle...

Alumina ceramic lined components provide superior ...

95% al₂o₃ ceramic sleeves provide exceptional hard...