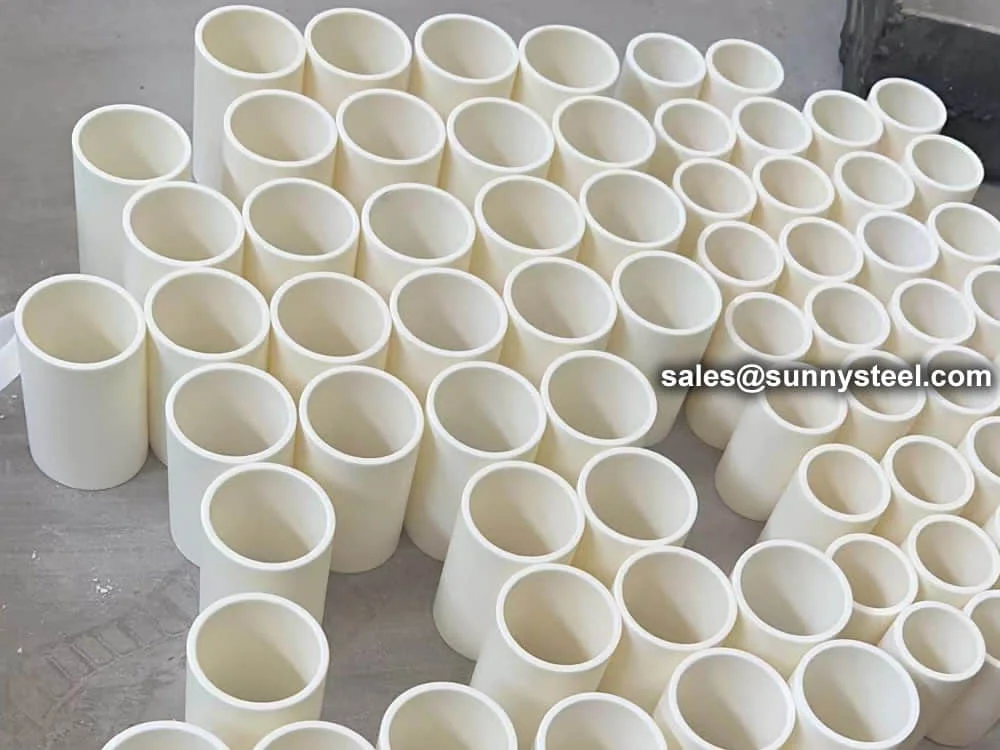

High-purity Alumina Ceramic Sleeves Designed For Abrasion Protection In Harsh Environments.

95% al₂o₃ ceramic sleeves provide exceptional hardness and durability, ideal for lining pipes and equipment exposed to severe abrasion.

High-purity Alumina Ceramic Sleeves Designed For Abrasion Protection In Harsh Environments.

95% al₂o₃ ceramic sleeves provide exceptional hardness and durability, ideal for lining pipes and equipment exposed to severe abrasion.

Al₂O₃

A 95% Al₂O₃ ceramic sleeve is a cylindrical component made from alumina (aluminum oxide) ceramic material with a 95% purity level.

This type of sleeve is known for its high strength, excellent wear and corrosion resistance, and good high-temperature resistance, making it suitable for demanding industrial applications like those found in the mining, power generation, chemical processing, and oil and gas industries.

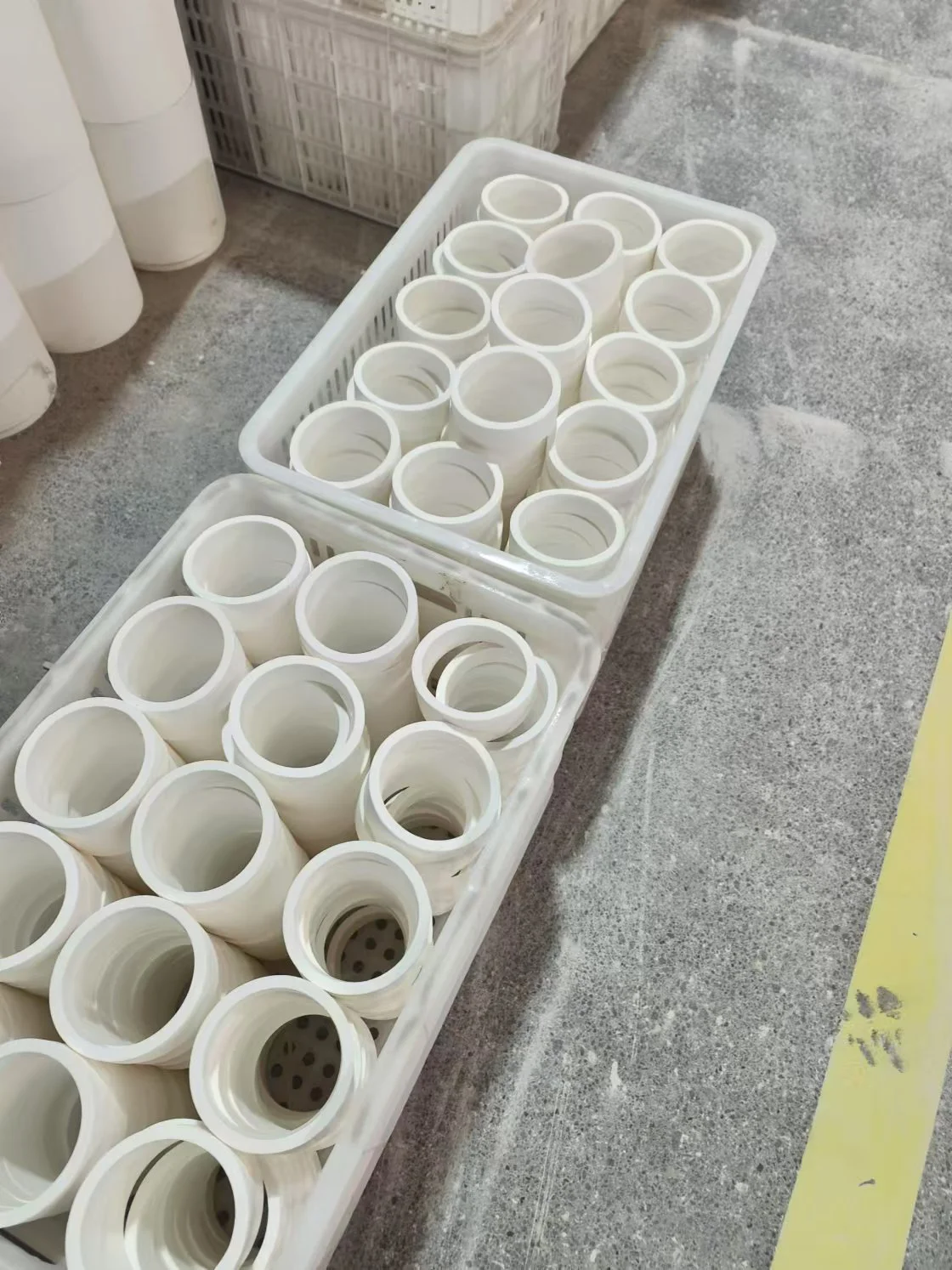

The 95% Al₂O₃ ceramic sleeve is manufactured from high-purity aluminum oxide powder, providing outstanding hardness and wear resistance. These sleeves serve as protective liners inside pipes, valves, elbows, and other industrial components subjected to abrasive slurry and powder flows.

With a Mohs hardness above 9, the ceramic sleeves effectively resist erosion, corrosion, and thermal shock, significantly extending the service life of equipment. Their precise manufacturing ensures a tight fit and reliable bonding with the steel substrate.

Widely applied in industries such as mining, power plants, cement, and chemical processing, 95% alumina ceramic sleeves are a cost-effective solution for reducing maintenance and downtime while enhancing operational efficiency.

| Material | Unit | 95% Al2O3 | 96% Al2O3 | 99% Al2O3 | 99.5% Al2O3 | 99.8% Al2O3 |

|---|---|---|---|---|---|---|

| Purity | % | 95 | 96 | 99 | 99.5 | 99.8 |

| Color | --- | White/Pink | White | Ivory | Ivory | Ivory |

| Density | g/cm³ | 3.65 | 3.72 | 3.85 | 3.90 | 3.92 |

| Water Absorption | % | 0 | 0 | 0 | 0 | 0 |

| Moh's Hardness | --- | 9 | 9 | 9 | 9 | 9 |

| HV Hardness | --- | >1300 | >1300 | 1700 | 1750 | 1800 |

| Flexural Strength @25°C | MPa | 300 | 300 | 330 | 375 | 390 |

| Fracture Toughness | MPa·m1/2 | 3~4 | 3~4 | 3~4 | 4 | 4 |

| Compressive Strength (25°C) | MPa | 2200 | 2200 | 2350 | 2450 | 2500 |

| Thermal Conductivity @25°C | W/m·K | 18–22 | ≥24 | 27 | 29 | 32 |

| Thermal Expansion Coefficient (25–1000°C) | 10-6/°C | 8 | 8 | 8 | 8 | 8 |

| Thermal Shock Resistance | ΔT (°C) | 220 | 220 | 180–200 | 180–200 | 180–200 |

| Max. Working Temperature | °C | 1500 | 1500 | 1700 | 1750 | 1750 |

| Dielectric Strength | kV/mm | 16 | 17.2 | 20 | 22 | 22 |

| Electrical Resistivity @25°C | Ω·cm | 1014 | 1014 | 1014 | 1014 | 1014 |

| Dielectric Constant @1MHz | --- | 9 | 9 | 9.7 | 9.7 | 9.8 |

| Dielectric Loss (Tan δ) @1MHz | --- | 0.0004 | 0.0002 | 0.0002 | 0.0001 | 0.0001 |

Compare physical, thermal, and electrical properties across various purity levels of alumina ceramic (Al2O3).

| Parameter | Details |

|---|---|

| Material Options | Alumina (40%–99.8%), Zirconia, Silicon Carbide, Silicon Nitride |

| Forming Methods | Extrusion, Dry Pressed, Hot Pressed, CIM, ISO Pressed |

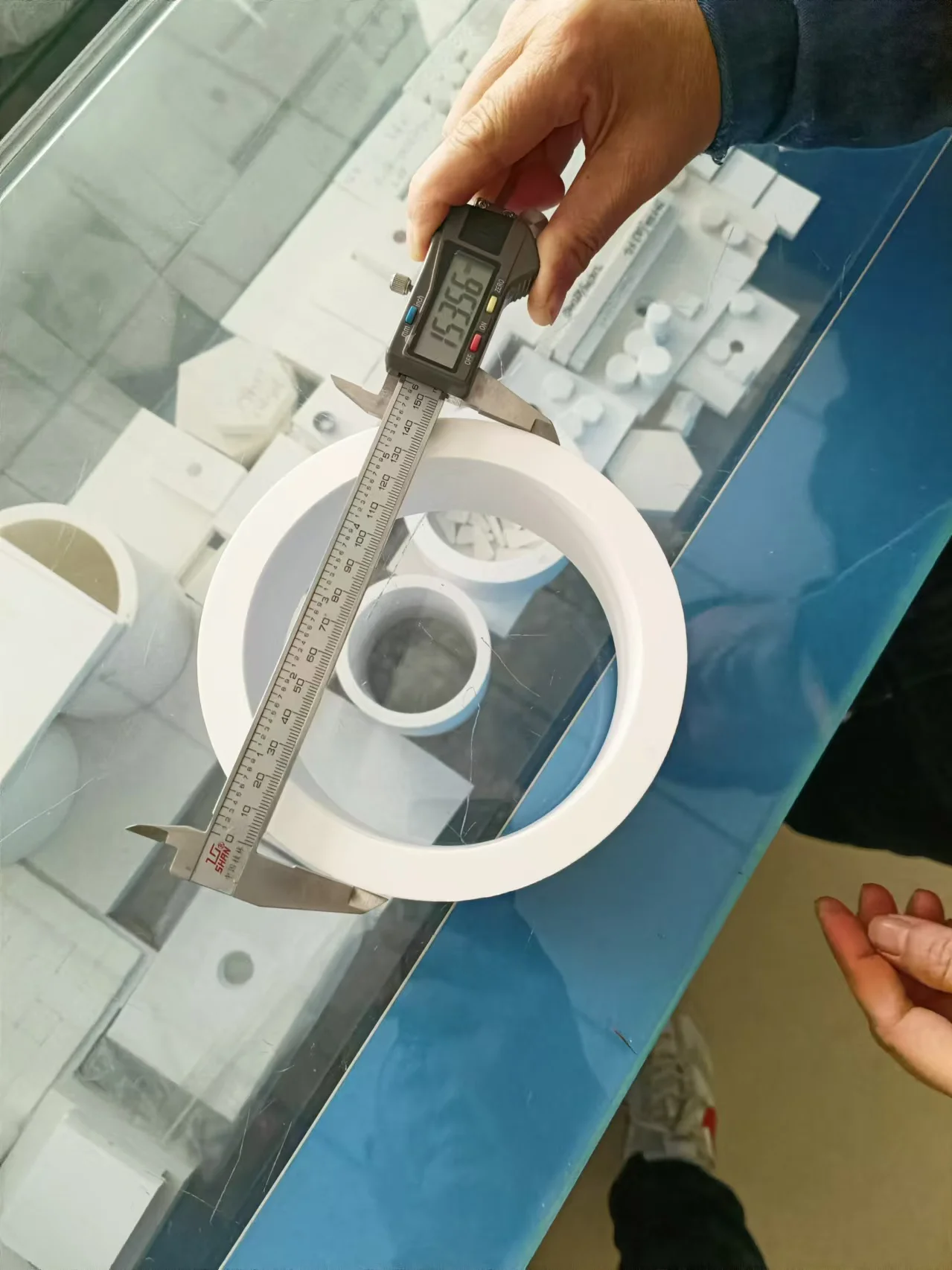

| Dimensional Capability | Min. ID: 1mm; Max. OD: 800mm |

| Dimensional Tolerance | OD ±0.005mm, ID ±0.01mm, Length ±0.001mm |

| Surface Treatment | Polished, Glazed, or Metalized |

| Secondary Processing | CNC machining, lapping, threading, drilling, grinding, laser cutting |

Standard manufacturing capabilities and tolerances for ceramic tube products.

Aluminum oxide (al₂o₃) ceramic provides outstandin...

Alumina ceramic cyclone liner tubes offer superior...

Wear-resistant alumina ceramic rings offer excelle...

Alumina ceramic lined components provide superior ...

Alumina ceramic insulation pipes provide superior ...