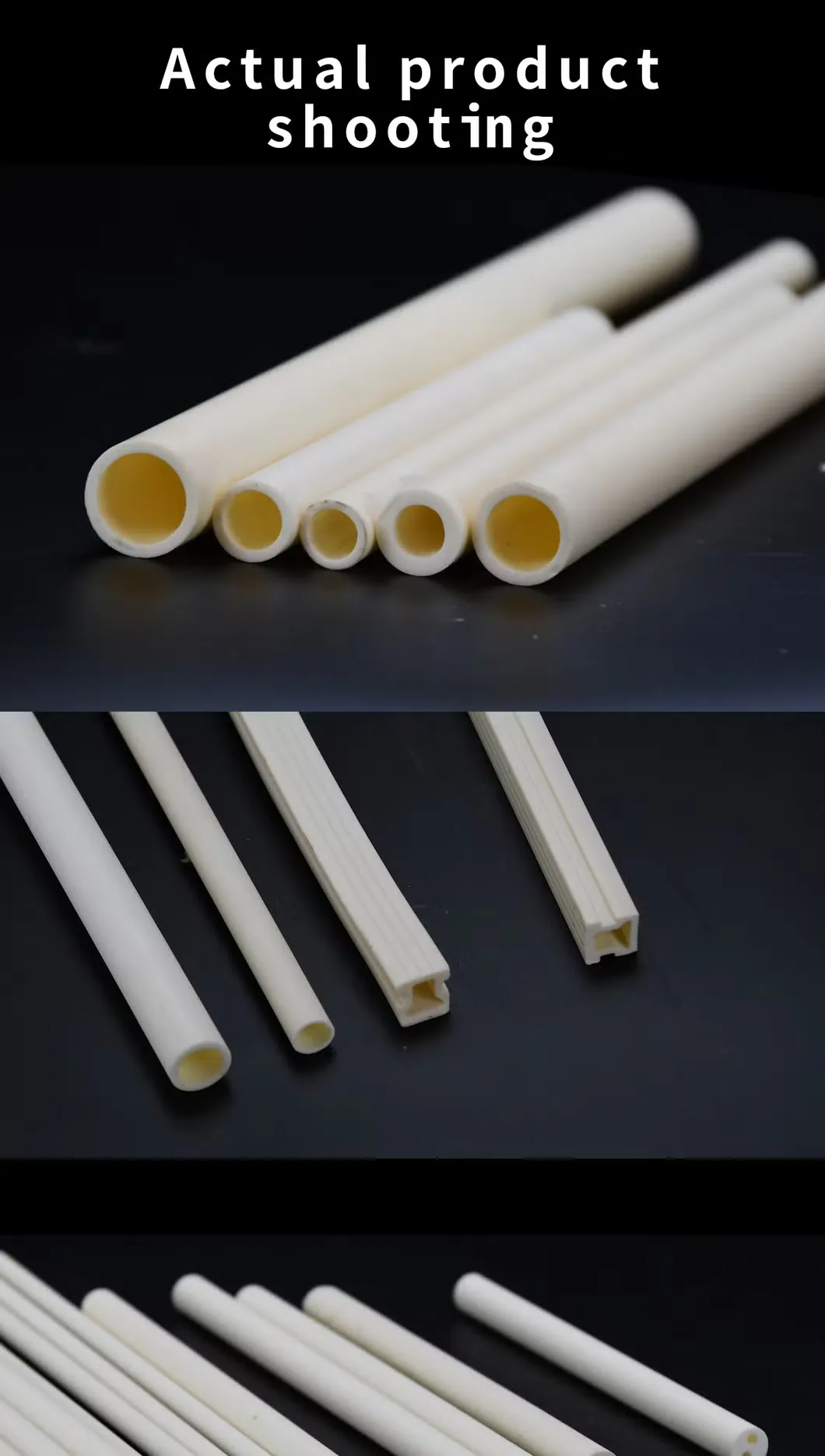

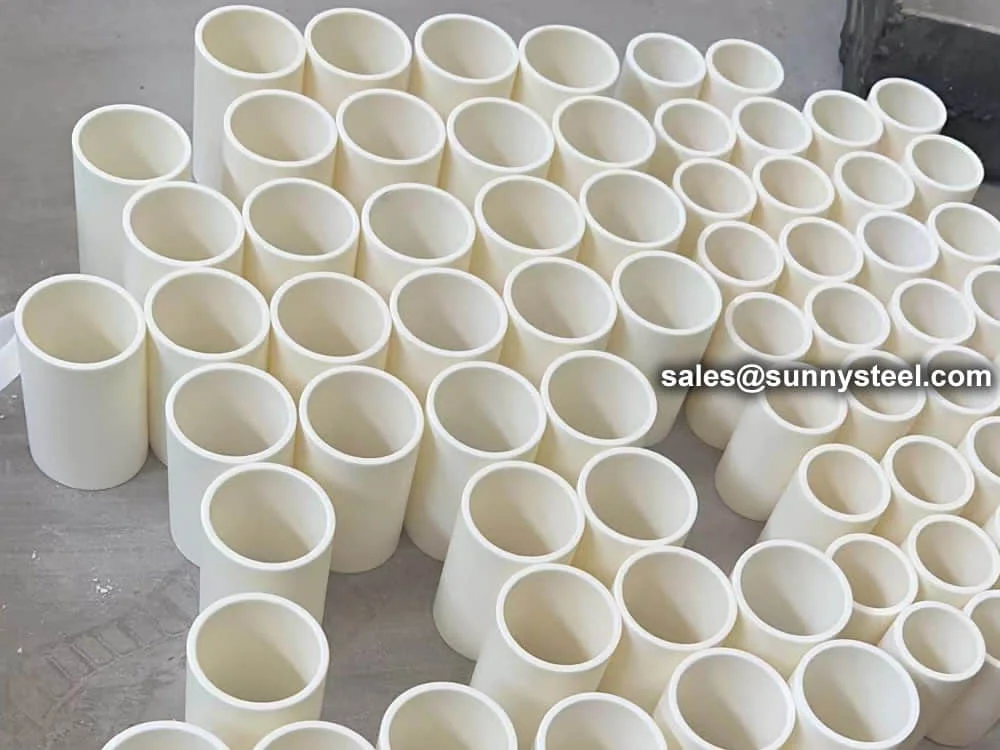

Ultra-pure Alumina Ceramic Sleeves For High-precision, High-demand Industrial Applications

99% al₂o₃ ceramic sleeves offer unmatched hardness, corrosion resistance, and thermal stability for critical wear lining applications.

Ultra-pure Alumina Ceramic Sleeves For High-precision, High-demand Industrial Applications

99% al₂o₃ ceramic sleeves offer unmatched hardness, corrosion resistance, and thermal stability for critical wear lining applications.

The 99% Al₂O₃ ceramic sleeve is a premium-grade technical ceramic component engineered for the most demanding industrial conditions. Manufactured using ultra-fine, high-purity aluminum oxide, this sleeve delivers exceptional hardness (Mohs 9+), low porosity, and high mechanical strength.

Compared to standard 95% alumina, the 99% version provides superior resistance to acids, alkalis, high-velocity particulates, and extreme temperatures—making it the ideal choice for critical components in power plants, mining operations, chemical processing, and high-temperature kiln systems.

These ceramic sleeves are commonly used as linings for steel pipes, elbows, tees, and equipment housings. They protect against internal abrasion, reduce maintenance frequency, and increase equipment lifespan. Their dimensional accuracy and surface finish make them well-suited for precision assemblies.

Sunny Steel offers customizable dimensions, lengths, and thicknesses, ensuring optimal fit and performance for your unique system needs. Whether applied in pneumatic conveying, slurry transport, or reactor linings, 99% alumina ceramic sleeves ensure long-lasting protection and operational reliability.

| Material | Unit | 95% Al2O3 | 96% Al2O3 | 99% Al2O3 | 99.5% Al2O3 | 99.8% Al2O3 |

|---|---|---|---|---|---|---|

| Purity | % | 95 | 96 | 99 | 99.5 | 99.8 |

| Color | --- | White/Pink | White | Ivory | Ivory | Ivory |

| Density | g/cm³ | 3.65 | 3.72 | 3.85 | 3.90 | 3.92 |

| Water Absorption | % | 0 | 0 | 0 | 0 | 0 |

| Moh's Hardness | --- | 9 | 9 | 9 | 9 | 9 |

| HV Hardness | --- | >1300 | >1300 | 1700 | 1750 | 1800 |

| Flexural Strength @25°C | MPa | 300 | 300 | 330 | 375 | 390 |

| Fracture Toughness | MPa·m1/2 | 3~4 | 3~4 | 3~4 | 4 | 4 |

| Compressive Strength (25°C) | MPa | 2200 | 2200 | 2350 | 2450 | 2500 |

| Thermal Conductivity @25°C | W/m·K | 18–22 | ≥24 | 27 | 29 | 32 |

| Thermal Expansion Coefficient (25–1000°C) | 10-6/°C | 8 | 8 | 8 | 8 | 8 |

| Thermal Shock Resistance | ΔT (°C) | 220 | 220 | 180–200 | 180–200 | 180–200 |

| Max. Working Temperature | °C | 1500 | 1500 | 1700 | 1750 | 1750 |

| Dielectric Strength | kV/mm | 16 | 17.2 | 20 | 22 | 22 |

| Electrical Resistivity @25°C | Ω·cm | 1014 | 1014 | 1014 | 1014 | 1014 |

| Dielectric Constant @1MHz | --- | 9 | 9 | 9.7 | 9.7 | 9.8 |

| Dielectric Loss (Tan δ) @1MHz | --- | 0.0004 | 0.0002 | 0.0002 | 0.0001 | 0.0001 |

Compare physical, thermal, and electrical properties across various purity levels of alumina ceramic (Al2O3).

| Parameter | Details |

|---|---|

| Material Options | Alumina (40%–99.8%), Zirconia, Silicon Carbide, Silicon Nitride |

| Forming Methods | Extrusion, Dry Pressed, Hot Pressed, CIM, ISO Pressed |

| Dimensional Capability | Min. ID: 1mm; Max. OD: 800mm |

| Dimensional Tolerance | OD ±0.005mm, ID ±0.01mm, Length ±0.001mm |

| Surface Treatment | Polished, Glazed, or Metalized |

| Secondary Processing | CNC machining, lapping, threading, drilling, grinding, laser cutting |

Standard manufacturing capabilities and tolerances for ceramic tube products.

Aluminum oxide (al₂o₃) ceramic provides outstandin...

Alumina ceramic cyclone liner tubes offer superior...

Wear-resistant alumina ceramic rings offer excelle...

Alumina ceramic lined components provide superior ...

95% al₂o₃ ceramic sleeves provide exceptional hard...