High-hardness Ceramic Sleeves Designed To Withstand Severe Abrasion And Corrosion In Tough Environments

Alumina ceramic is the most widely applied technical ceramics which has high hardness and mechanical strength, good wear resistance, high temperature resistance, good electrical insulation and good resistance to corrosion etc.

High-hardness Ceramic Sleeves Designed To Withstand Severe Abrasion And Corrosion In Tough Environments

Alumina ceramic is the most widely applied technical ceramics which has high hardness and mechanical strength, good wear resistance, high temperature resistance, good electrical insulation and good resistance to corrosion etc. we could make custom manufacturing for alumina ceramic parts in required size and shapes.

Alumina ceramic, also known as Al2O3 ceramic or aluminium oxide ceramic, is an incredibly versatile technical ceramic material that is used in all kinds of industries. It offers so many benefits, including being highly strong, with excellent dielectric properties, and exceptional wear and corrosion resistance, as well as remarkable heat resistance. Alumina ceramic is one of the hardest and most wear-resistant materials on the planet, and it is so tough that diamond tools are required to machine it after sintering. Its incredible versatility allows it to be used in a wide range of industries, from machinery and electrical and electronics to semiconductors, petroleum, chemicals, textiles, and more.

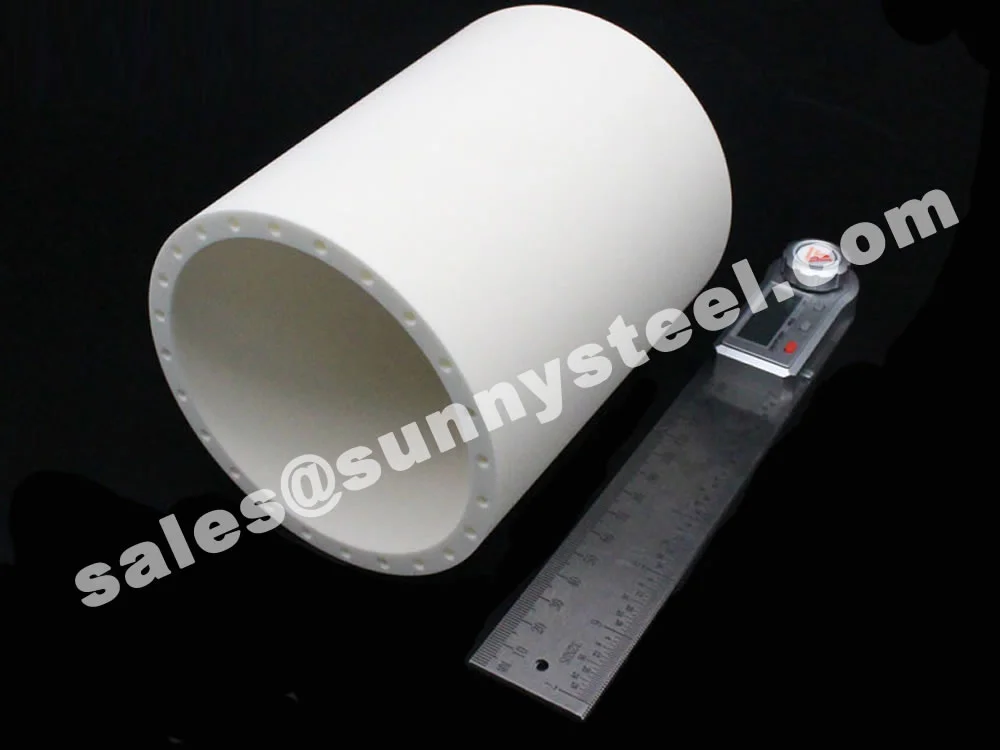

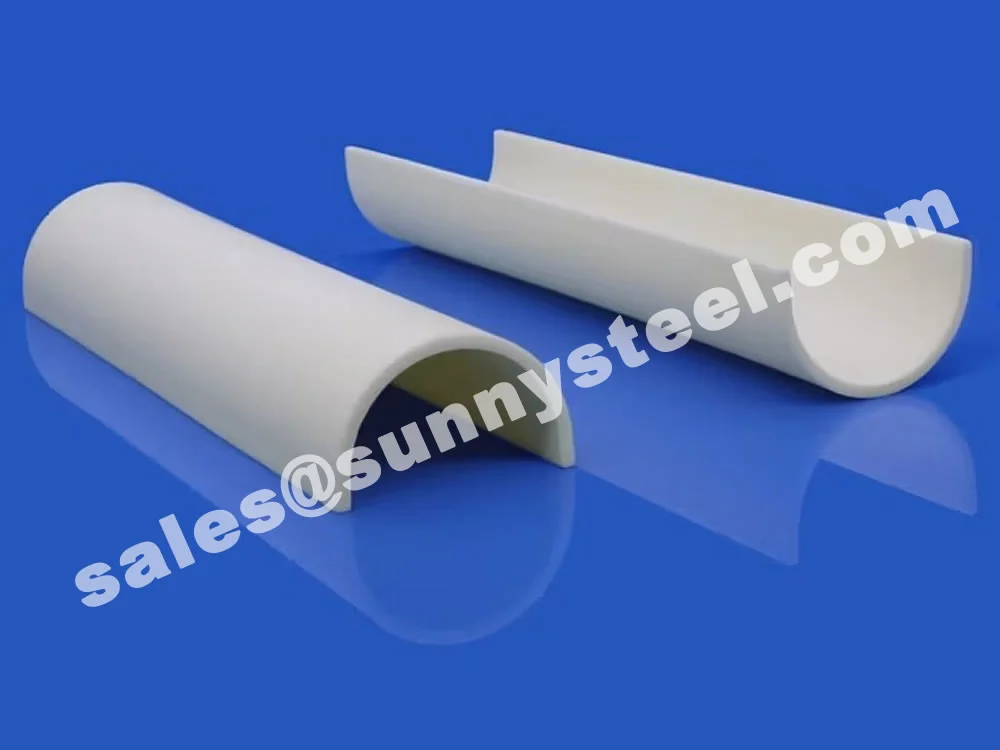

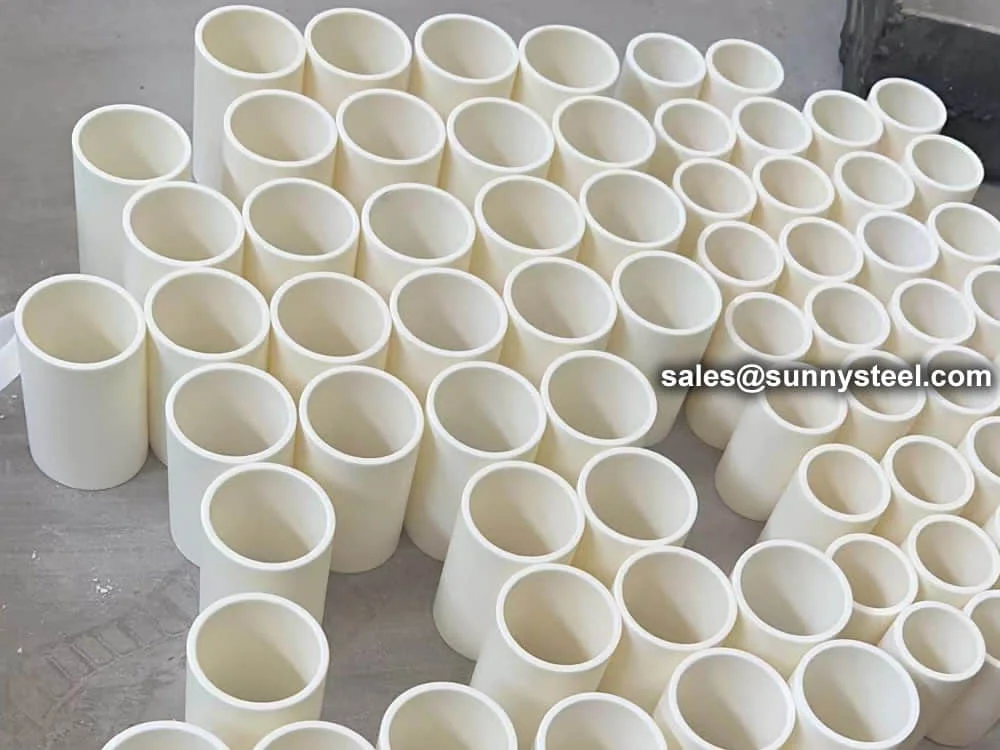

The Wear Resistant Al₂O₃ Alumina Ceramic Sleeve is a high-performance component made from aluminum oxide with purity ranging from 92% to 99%. These sleeves are engineered to serve as internal linings in pipelines, fittings, elbows, and machinery parts that face constant abrasion, corrosion, or thermal stress.

Thanks to their ultra-hard ceramic matrix (Mohs hardness > 9), Al₂O₃ sleeves effectively prevent wear caused by solid particle flows, such as fly ash, mineral slurries, cement powder, or coal dust. Their chemical inertness makes them compatible with acidic and alkaline media, while their thermal resistance enables use in high-temperature systems (up to 1500°C).

These sleeves are widely adopted in:

Pneumatic and hydraulic conveying systems

Ash handling pipelines in thermal power plants

Mineral processing lines in mining

Cement and chemical production

Sunny Steel offers these ceramic sleeves in multiple configurations, including straight tubes, flanged liners, and composite pipe sections with outer steel reinforcement. Custom sizing and seamless bonding techniques ensure maximum wear life and compatibility with existing pipework.

By incorporating wear-resistant Al₂O₃ ceramic sleeves into your system, you can drastically reduce equipment downtime, improve safety, and extend the lifecycle of components exposed to abrasive or corrosive flow media.

Everything you need to know about ceramic sleeve lined pipes and their installation

Aluminum oxide (al₂o₃) ceramic provides outstandin...

Alumina ceramic cyclone liner tubes offer superior...

Wear-resistant alumina ceramic rings offer excelle...

Alumina ceramic lined components provide superior ...

95% al₂o₃ ceramic sleeves provide exceptional hard...

Alumina ceramic insulation pipes provide superior ...