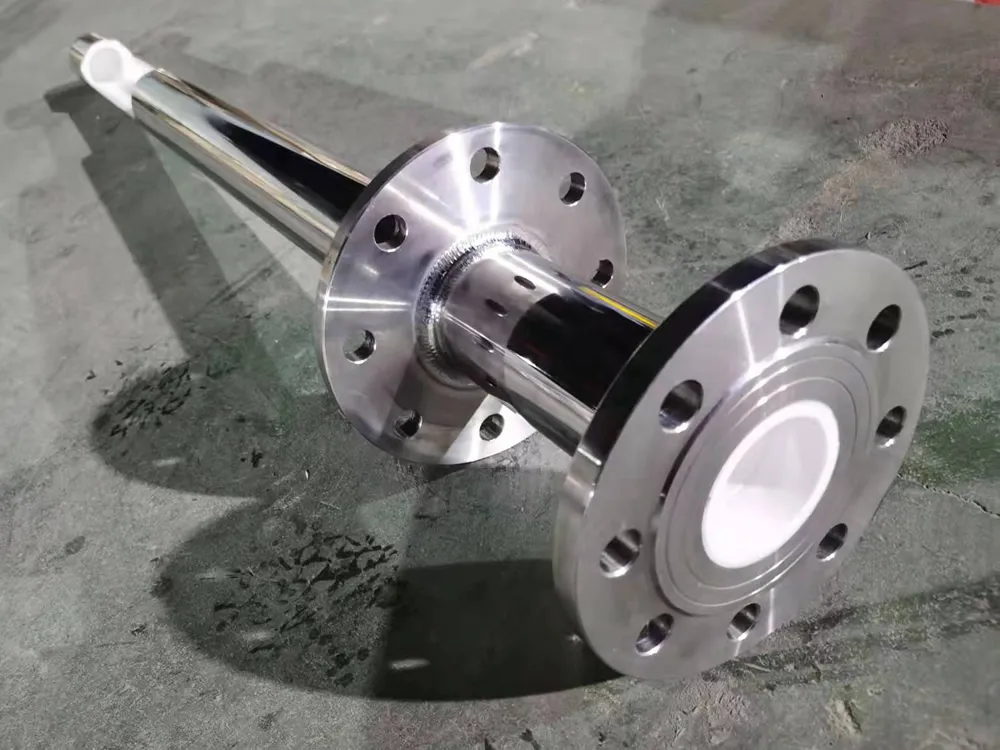

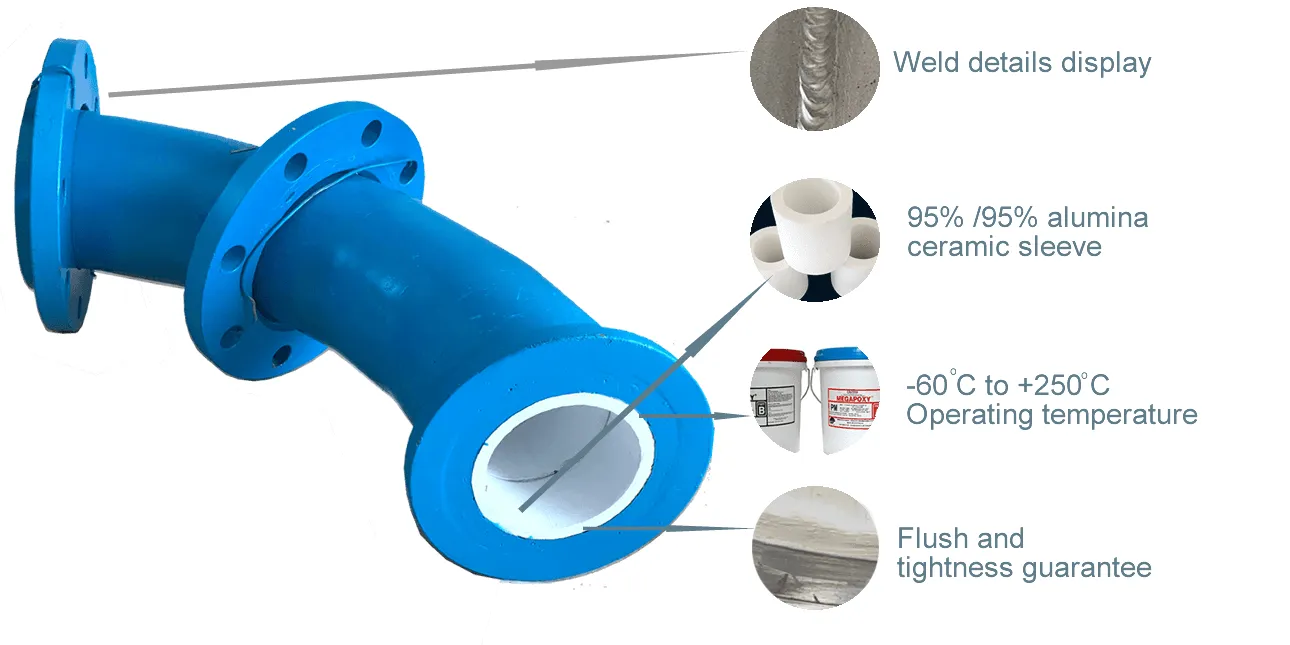

Zirconia lined composite pipeline

High-toughness Ceramic Lining Ideal For Abrasive And Corrosive Material Transport Under High Temperature And Pressure

Zirconia lined composite pipelines offer unmatched wear resistance, toughness, and chemical stability, ideal for transporting abrasive and corrosive media in demanding environments.

Zirconia lined composite pipeline

High-toughness Ceramic Lining Ideal For Abrasive And Corrosive Material Transport Under High Temperature And Pressure

Zirconia lined composite pipelines offer unmatched wear resistance, toughness, and chemical stability, ideal for transporting abrasive and corrosive media in demanding environments.