Silicon nitride structural parts are advanced ceramic components known for their outstanding mechanical strength, wear resistance, and thermal stability. These high-performance ceramics are engineered to operate in the most demanding industrial environments where traditional materials fail due to abrasion, corrosion, or extreme heat.

Manufactured using hot-pressing and advanced sintering techniques, silicon nitride parts offer a unique combination of high flexural strength, excellent fracture toughness, and low thermal expansion. These properties make them especially effective in high-temperature, chemically aggressive, or mechanically dynamic settings.

Typical applications include:

-

Bearings, seals, and guides in semiconductor and automotive industries

-

Insulating components in high-voltage and RF electronics

-

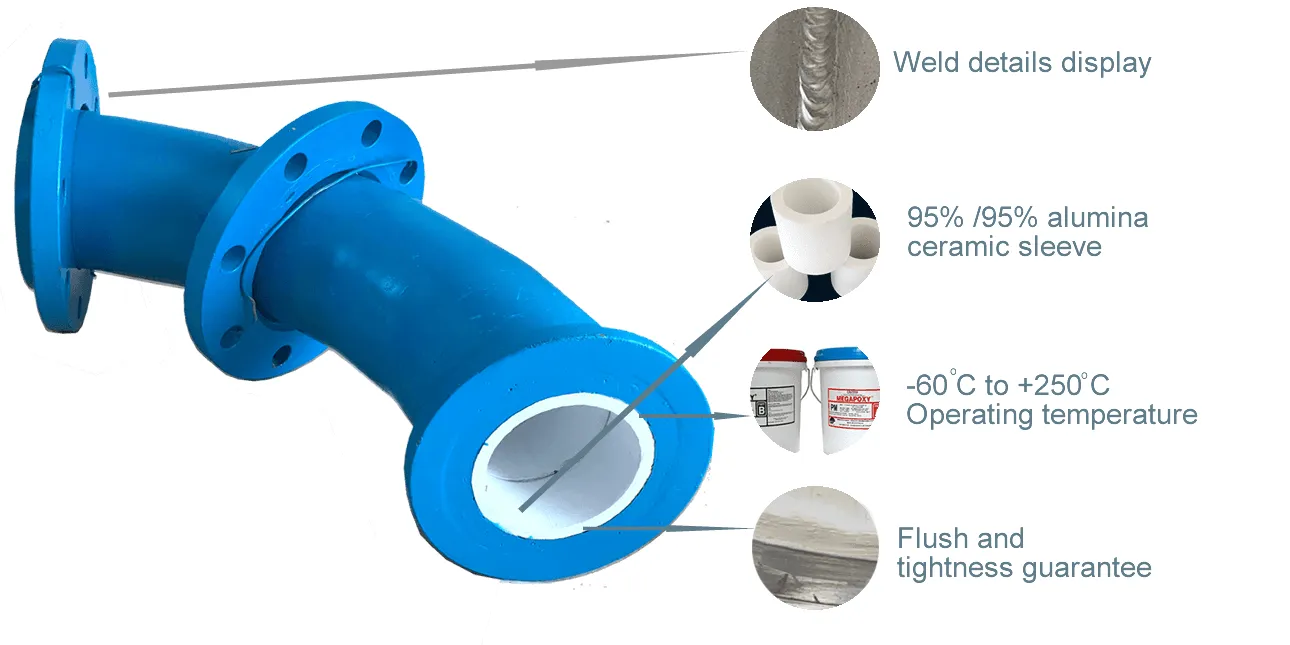

Nozzles, plungers, and sleeves in chemical processing systems

-

Structural supports and fastening components in high-temperature kilns

-

Precision mechanical parts in aerospace and energy sectors

Unlike other ceramics such as alumina or zirconia, silicon nitride parts can withstand rapid thermal cycling, maintain stability at temperatures up to 1400°C, and resist chemical degradation from acids, alkalis, and molten metals. This makes them a preferred choice for wear resistant ceramic components where durability and performance are critical.

We offer custom silicon nitride structural parts tailored to your exact specifications, including special shapes, sizes, and connection methods. Our engineering team works closely with clients to ensure optimal material selection and integration with metal or composite systems.

With a smooth surface finish, lightweight design, and long service life, our structural ceramic components significantly reduce maintenance costs and downtime in industrial operations.