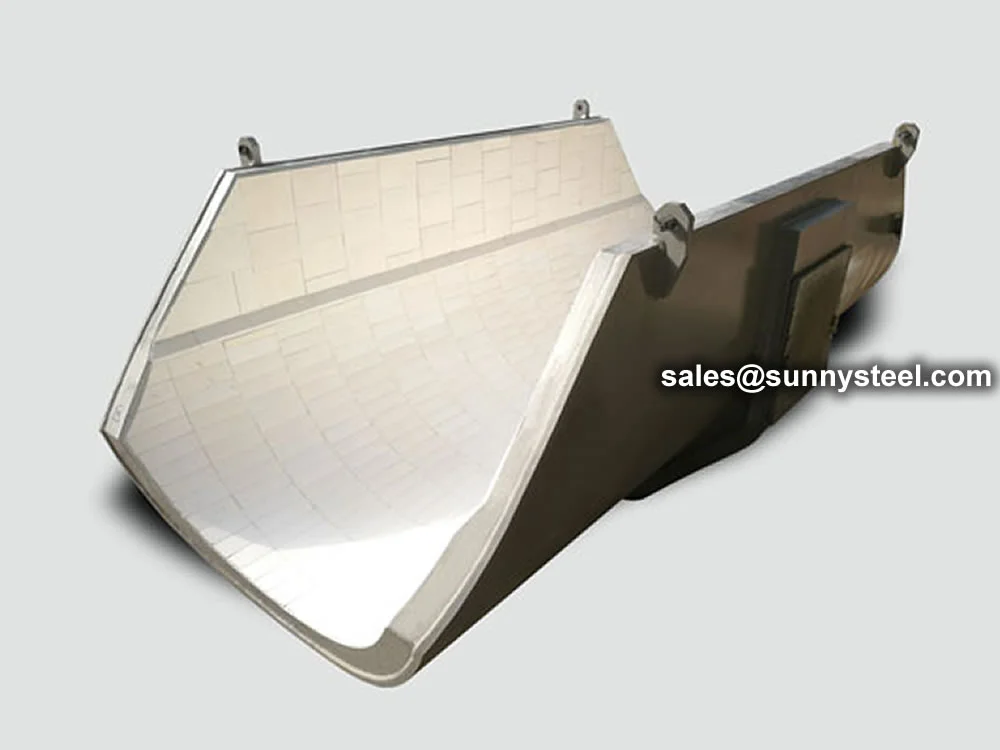

Chute Wear Liner

Durable Lining Solution For Bulk Material Handling Chutes Exposed To Wear, Impact, And Corrosion.

Chute wear liners extend equipment life by protecting material transfer points from abrasion, impact, and corrosion in mining, cement, and power industries.

Chute Wear Liner

Durable Lining Solution For Bulk Material Handling Chutes Exposed To Wear, Impact, And Corrosion.

Chute wear liners extend equipment life by protecting material transfer points from abrasion, impact, and corrosion in mining, cement, and power industries.