Superior Wear Protection

Ceramic tiles provide exceptional resistance to abrasive materials with hardness exceeding HRA80, delivering 100x more wear resistance than manganese steel.

Maximum Abrasion Protection For Industrial Flow Systems

Alumina ceramic lined wear resistant elbows offer high-strength abrasion protection and extended service life, ideal for redirecting abrasive flow in mining, power, and cement pipelines.

Maximum Abrasion Protection For Industrial Flow Systems

Alumina ceramic lined wear resistant elbows offer high-strength abrasion protection and extended service life, ideal for redirecting abrasive flow in mining, power, and cement pipelines.

More Wear Resistant than Manganese Steel

Maximum Operating Temperature

Alumina Content for Superior Hardness

Service Life Increase

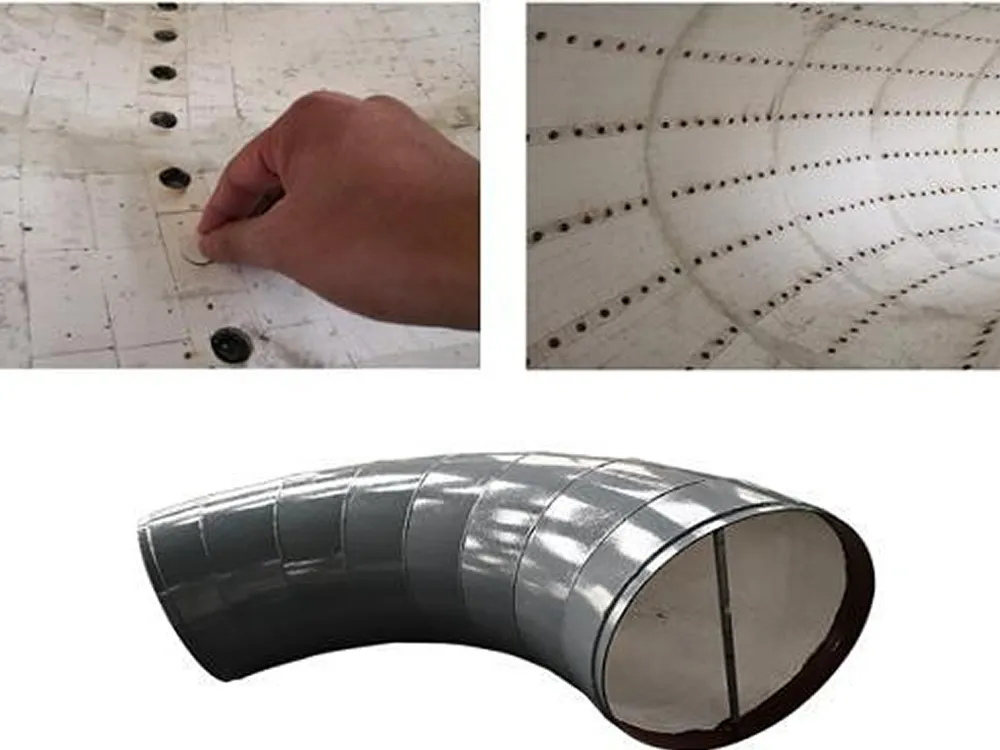

Ceramic tile lined pipes represent a sophisticated engineering solution that combines the structural integrity of steel with the exceptional wear resistance of advanced ceramic materials.

These specialized pipelines feature ceramic tiles lining strategically positioned inside a steel pipe, creating a composite structure that delivers outstanding performance in demanding industrial applications. The ceramic tiles are typically manufactured from high-grade materials including alumina, zirconia, silicon carbide, or other advanced ceramics.

Ceramic tiles provide exceptional resistance to abrasive materials with hardness exceeding HRA80, delivering 100x more wear resistance than manganese steel.

Operates effectively from -50°C to 800°C, with ceramic materials withstanding temperatures above 1000°C for extreme applications.

Replaces expensive stainless steel and alloy pipes while providing 5x longer service life and 3x better performance-cost ratio.

| Property | Value | Unit |

|---|---|---|

| Al2O3 Content | 90-95% | % |

| Hardness | HV1400-1600 | HV |

| Rockwell Hardness | ≥HRA80 | HRA |

| Density | 3.6 | g/cm³ |

| Compressive Strength | ≥850 | MPa |

| Max Temperature | 1000+ | °C |

| Comparison | Performance Ratio | Material |

|---|---|---|

| Wear Resistance | 100x | vs Manganese Steel |

| Wear Resistance | 20x | vs High Chromium Cast Iron |

| Wear Resistance | Several times | vs Wear Resistant Rubber |

| Service Life | 5x | vs Traditional Materials |

| Cost Performance | 3x | Better Ratio |

| Bonding Strength | 300 kg/cm² | at 500°C |

High-purity alumina powder is mixed with binders and pressed into desired tile shapes using high-pressure forming equipment, then sintered at 1600–1730°C.

Steel pipe substrate undergoes thorough rust removal, decontamination, and surface roughening to provide optimal bonding surface.

Ceramic tiles are bonded using high-strength, temperature-resistant adhesives with precise control of application and curing conditions.

Comprehensive testing including raw material verification, process monitoring, and final inspection with non-destructive testing methods.

Advanced welding techniques secure ceramic tiles through small holes, providing additional mechanical fastening beyond adhesive bonding.

Complete dimensional verification, bonding integrity testing, and performance validation to ensure optimal quality and reliability.

| No. | Process | Standard | Inspection |

|---|---|---|---|

| 1 | Cleaning the inner surface | Remove all debris and floating ash inside the steel pipe and equipment thoroughly. | Inspected by the construction supervisor. |

| 2 | Rust, oil, and paint removal | Completely eliminate rust, grease, and paint to reveal metallic luster. Polish using tools and wipe clean with cloth. | Approved by quality inspector before proceeding. |

| 3 | Adhesive preparation | Mix strictly as per ratio; stir ≥4 times. If filler is added, mix adhesive first and then mix all ≥3 times. | Handled by assigned personnel. |

| 4 | Surface repair | Fill any potholes on aged surfaces using embedded material before applying ceramic tiles. | Quality inspector approval required. |

| 5 | Tile pasting | Tiles must be clean; adhesive must be applied evenly to tile and pipe surface to ensure uniform thickness. | Inspected by responsible construction supervisor. |

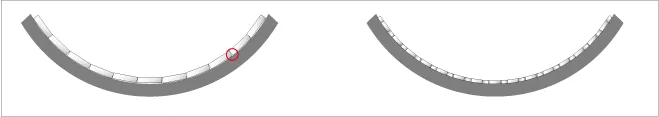

| 6 | Gap and edge repair | Gaps >3mm must be filled with wear-resistant filler. Edges should be neatly trimmed and sealed. | Final inspection by quality and construction heads; submitted to client for approval. |

| 7 | Maintenance | Allow natural curing for ≥12 hours after completion and acceptance by Party A. | — |

Detailed production requirements for pasting wear-resistant ceramic tiles inside steel pipes.

Ceramic tile lined pipe is a composite product developed with advanced technology, combining a durable steel shell and an inner lining of wear-resistant ceramic for superior performance and extended lifespan.

Using interlocking ceramic tubes bonded with high-strength adhesives and supported by welded steel fixtures, the design ensures reliable protection against abrasion. These pipes offer flexible installation, high durability, and cost-effective wear solutions.

Rockwell hardness of high alumina ceramics reaches HRA80–90, second only to diamond and significantly surpassing stainless and wear-resistant steels.

High alumina ceramics are 266 times more wear-resistant than manganese steel and 171.5 times more than high chromium cast iron, extending equipment service life over 10x.

With a stable inorganic oxide structure, high alumina ceramics resist acid, alkali, salt, and organic solvents without electrochemical corrosion.

High alumina ceramics can operate at temperatures up to 1400°C, suitable for extreme thermal environments.

Its smooth surface and low roughness (1/6 of steel) reduce flow resistance and prevent adhesion, supporting higher flow efficiency.

With density around 3.6g/cm³, high alumina ceramics are lighter than steel, simplifying transport and installation processes.

Designed for demanding environments requiring superior abrasion, corrosion, and thermal resistance.

The use of Ceramic tile lined pipe and fittings is ideal in services that are prone to erosive wear, and where standard pipe and fittings would fail within 24 months or less.

Efficiently convey coal ash, fly ash, and abrasive materials with reduced maintenance and extended life.

Handle abrasive ores and corrosive slurries in extreme mining environments with exceptional durability.

Transport clinker, limestone, fly ash, and slag with superior wear protection in harsh processing systems.

Safely transport corrosive fluids and abrasive chemicals while maintaining pipeline integrity.

Manage hot slag, scale, and other abrasive materials in extreme temperature steel-making environments.

Provide reliable wear and corrosion resistance for transport pipelines in drilling and refining processes.

Common applications where ceramic tile lining significantly improves wear resistance and extends service life.

| Ash Pipe & Elbows | Add-Mix Transport Lines | Coal Piping Clinker Chutes |

| Chutes | Coal Conduit Lining | Coal Handling Chute Lining |

| Fan Lining | Pulverizer Housing Liner | Coal Mill Pulverizer Cone Lining |

| Burner Feed Pipes | Classifier Cone Lining | Cullet Chutes & Hoppers |

| Cyclone Lining | Downcomer Pipe Lining | Coal Mill Exhauster Lining |

| Fan Housings | Drag Conveyor Lining | Coal Mill Pulverizer Lining |

Ceramic alumina linings offer five times the abrasion resistance of conventional ceramic materials. Proper use of these linings reduces maintenance costs and extends the service life of pipeline systems.

They are especially effective in hydraulic and pneumatic conveying systems, particularly steel tubes, where they significantly increase durability and efficiency.

Ceramic lining preserves steel pipe integrity under high abrasion conditions.

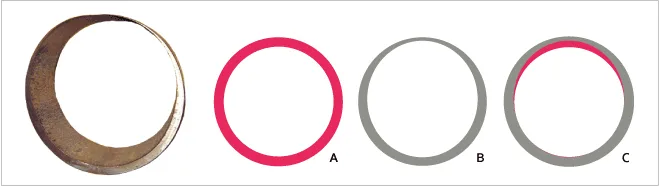

While metals are ductile, they lack abrasion resistance. In contrast, ceramics are extremely hard but brittle. The combination of a metal outer shell and ceramic inner lining creates a hybrid pipe with high strength and excellent wear resistance.

This synergy offers outstanding anti-wear and anti-corrosion performance. Ceramic-lined pipes are ideal for harsh operating conditions, significantly extending service life while reducing downtime and replacement costs.

Sunny Steel provides custom ceramic-lined steel pipes tailored to your dimensions, budget, and operating needs—ensuring the most efficient and reliable solution available.

A cross section of a steel pipe after 1 year of use

The perfect choice: resistance to abrasion is superior to all materials available on the market

Large diameter ceramic lined tile pipe offers supe...