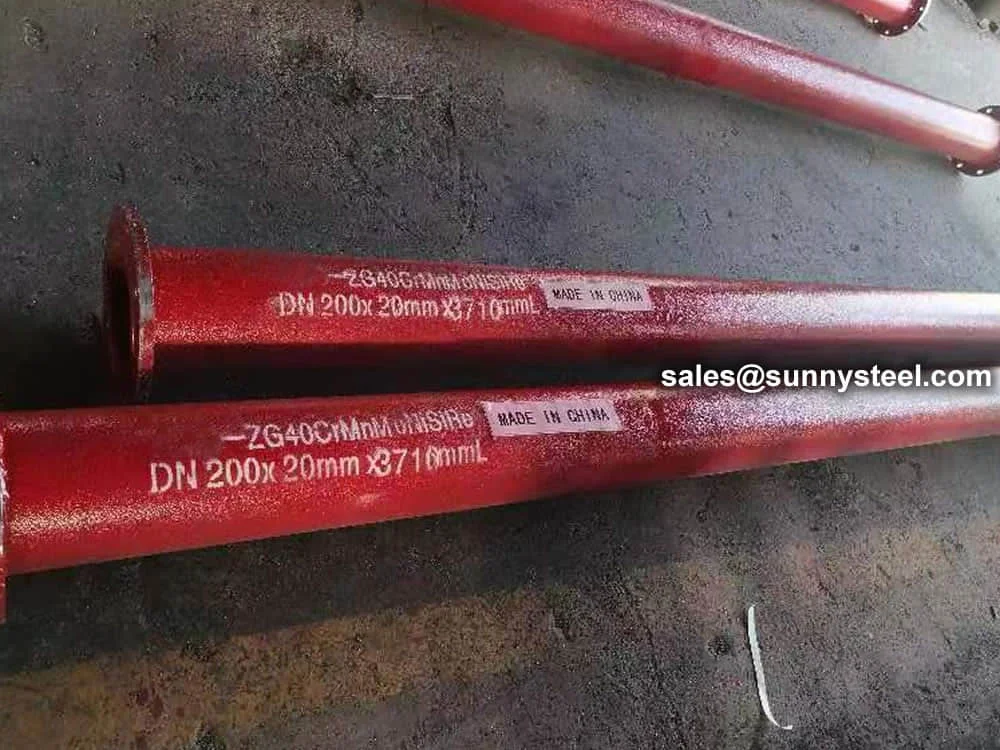

ZG40Cr8MnMoNiSiRe is a specialized rare earth alloy cast steel widely used in manufacturing wear-resistant pipes, elbows, and fittings for demanding industrial environments. The alloy combines approximately 0.40% carbon with key elements including chromium (8%), manganese, molybdenum, nickel, silicon, and rare earth elements to optimize hardness, toughness, and corrosion resistance.

The addition of rare earth metals enhances the alloy’s microstructure, improving grain refinement, wear resistance, and thermal stability. This cast steel exhibits excellent performance under high-velocity abrasive flow, impact loading, and corrosive conditions, making it ideal for coal slurry pipelines, ash handling, and power plant applications.

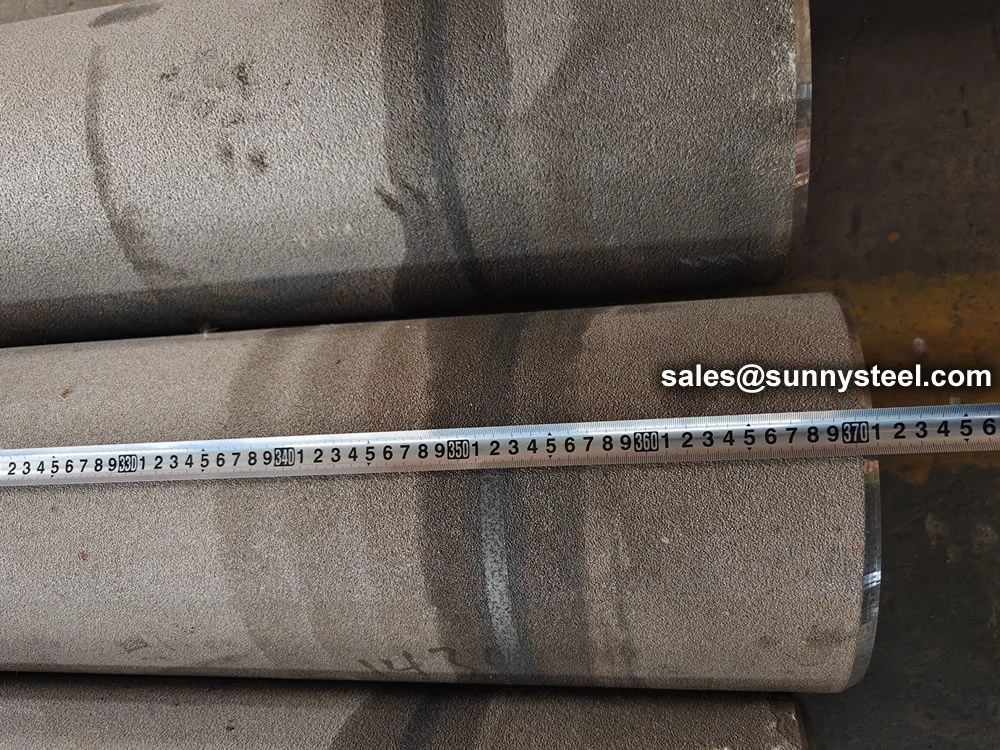

ZG40Cr8MnMoNiSiRe alloy cast steel features high tensile strength, impact toughness, and hardness (240–320 HB), allowing it to withstand severe erosive wear and thermal cycling up to 650°C. It reduces maintenance costs and prolongs equipment life in mining, cement, steel, and power generation industries.

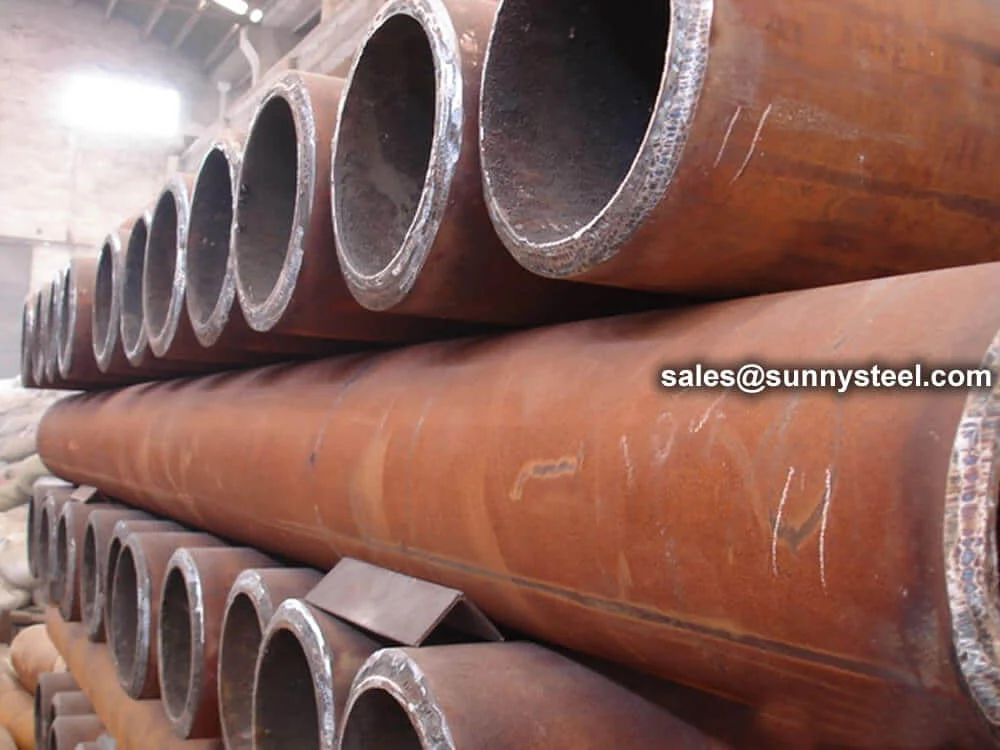

Also known as rare earth alloy wear-resistant steel or high-performance alloy cast steel, this material is crucial for fabricating durable industrial piping components and fittings designed for long-term reliability in extreme operating conditions.

Sunny Steel offers custom casting solutions, technical support, and quality assurance for ZG40Cr8MnMoNiSiRe products tailored to your project requirements.