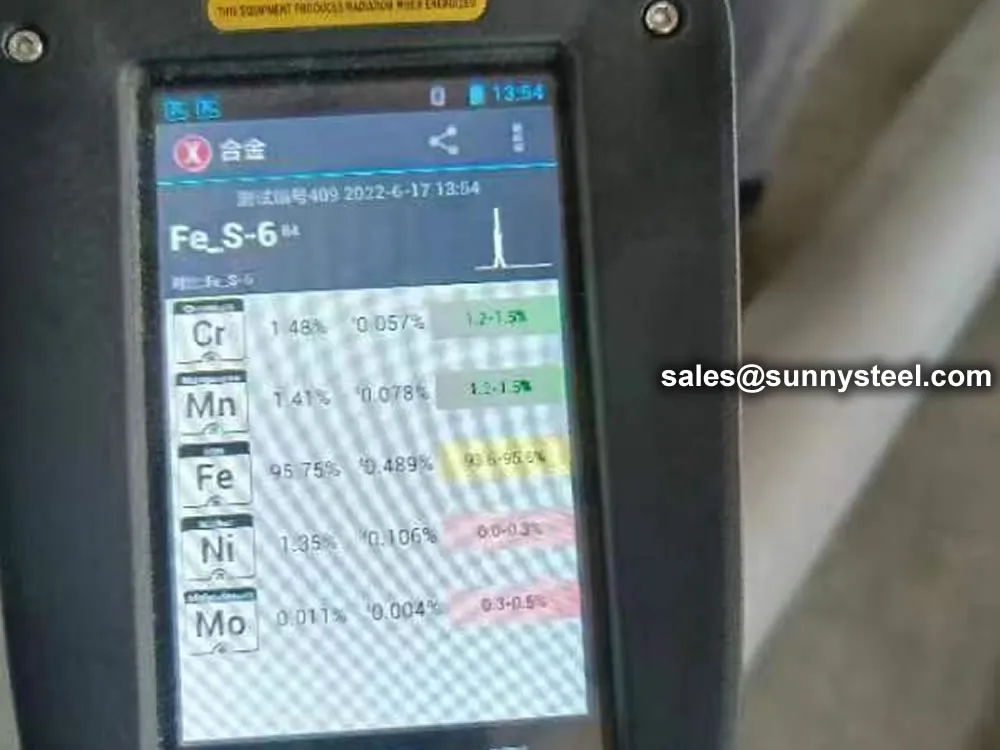

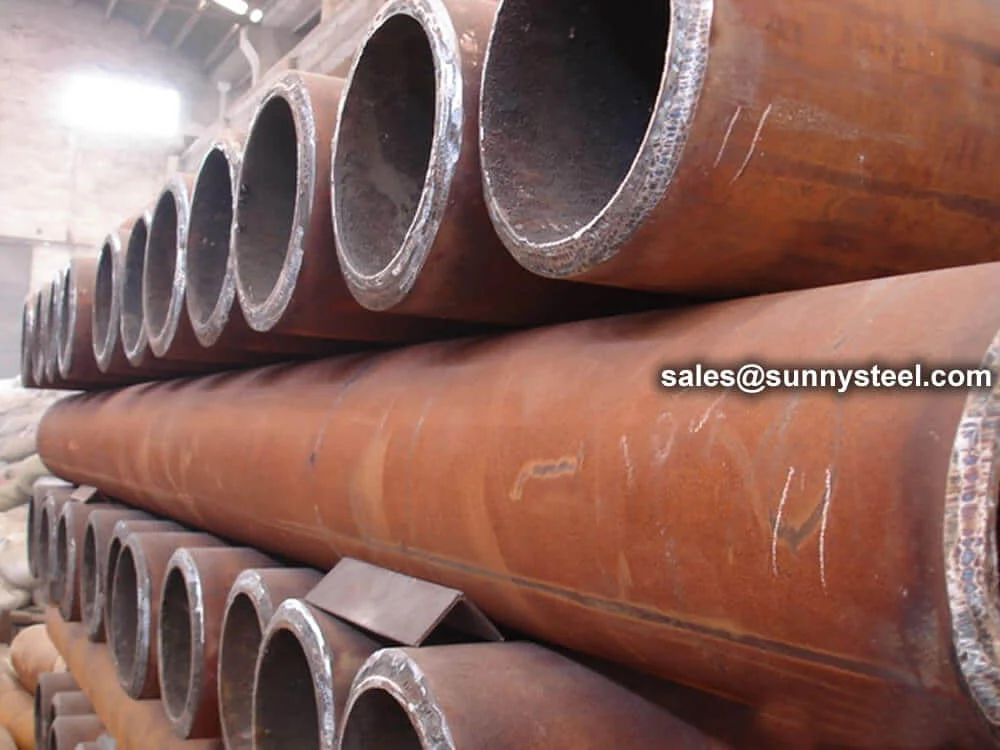

The Rare Earth Wear Resistant Alloy Elbow with Flange is a specialized pipe fitting designed for high-wear applications requiring directional flow changes and convenient installation. Made from high-strength alloy steel enhanced with rare earth elements such as cerium, lanthanum, and neodymium, this elbow provides superior resistance to abrasion, impact, and high-temperature degradation.

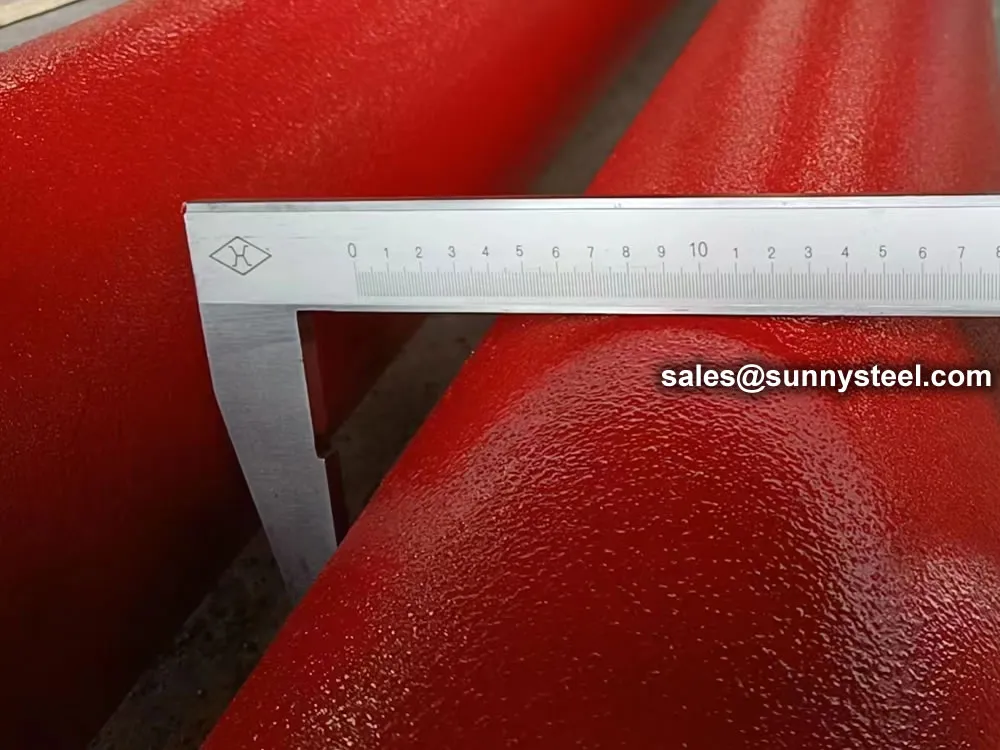

Its flanged ends allow for easy bolted connections in complex piping networks, reducing welding requirements and facilitating maintenance or replacement. The rare earth alloy structure offers high hardness (typically 240–320 HB), refined grain structure, and excellent thermal fatigue resistance—ideal for handling solid-laden slurries, ash, ore, and cement in high-velocity, high-pressure systems.

This product is commonly used in:

-

Power plants (coal ash handling, pneumatic conveying systems)

-

Mining operations (slurry lines, ore discharge systems)

-

Cement factories (dust return lines, clinker transport)

-

Steel mills (blast furnace residue systems)

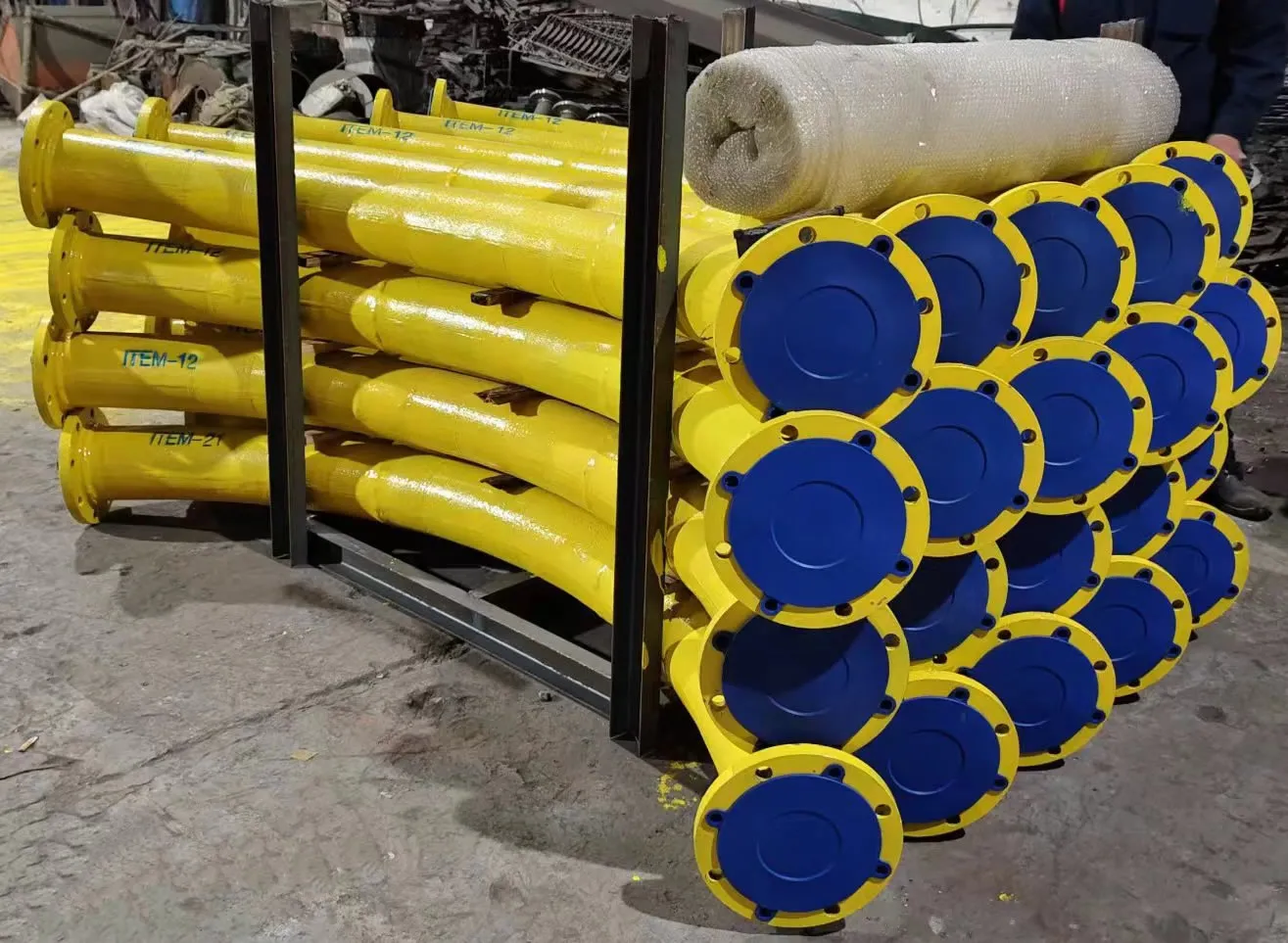

Also known as rare earth alloy flanged elbow, wear-resistant alloy elbow with flange, or abrasion-resistant elbow fitting, this component is essential for reducing pipeline wear at bends and minimizing costly downtime.

Sunny Steel offers complete customization in diameter, bend radius, flange type (DIN, ANSI, GB, etc.), and wall thickness to meet your system’s exact needs. All elbows are manufactured with strict quality controls and come with full technical support and international delivery.