Heavy-Duty Cast Pipe Made with Rare Earth Alloy for Extreme Wear, Impact, and Corrosion Resistance in Industrial Applications

The Rare Earth Alloy Wear Resisting Casting Pipe is a robust, high-performance solution for industrial environments where intense wear, erosion, and thermal shock are common. Cast using advanced alloy steel infused with rare earth elements—such as cerium, lanthanum, and neodymium—this pipe delivers enhanced mechanical strength, refined grain structure, and improved service life in abrasive material transport systems.

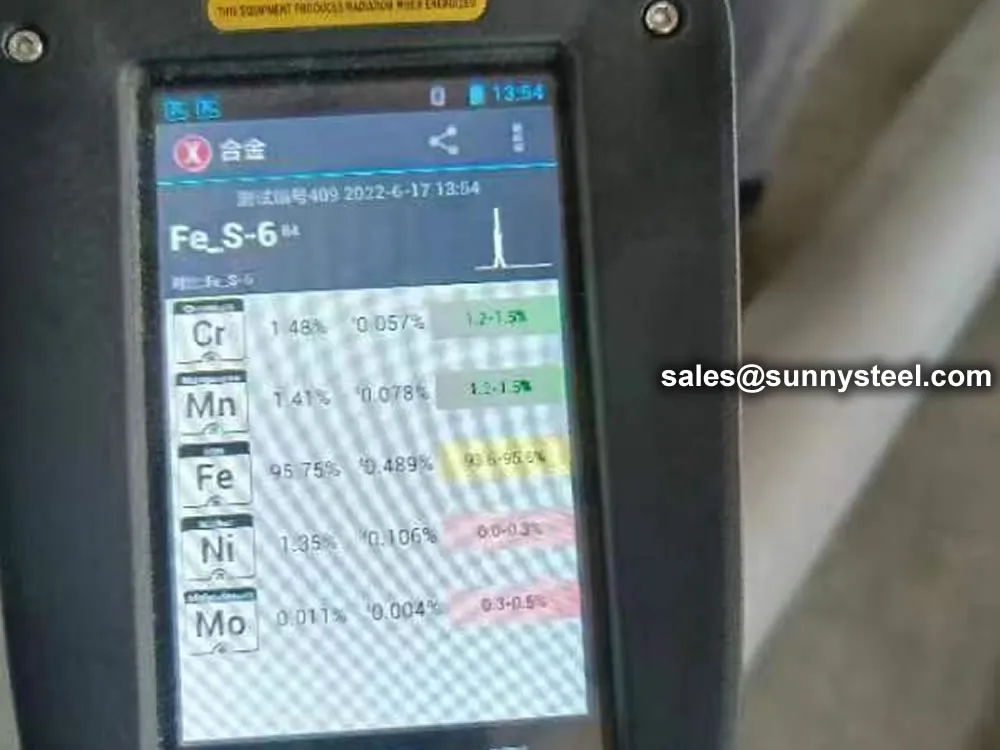

The alloy composition typically includes high levels of chromium, molybdenum, manganese, and nickel, resulting in superior hardness (HB 240–320), impact resistance, and corrosion protection. These properties make the pipe suitable for transporting high-velocity slurries, fly ash, coal, mineral ore, clinker, and other abrasive media.

This casting pipe is widely used in:

-

Coal-fired power plants (ash handling, pulverized coal transport)

-

Mining operations (slurry pipelines, tailings)

-

Cement and aggregate plants (dust and clinker conveying)

-

Steel production (slag and residue transfer)

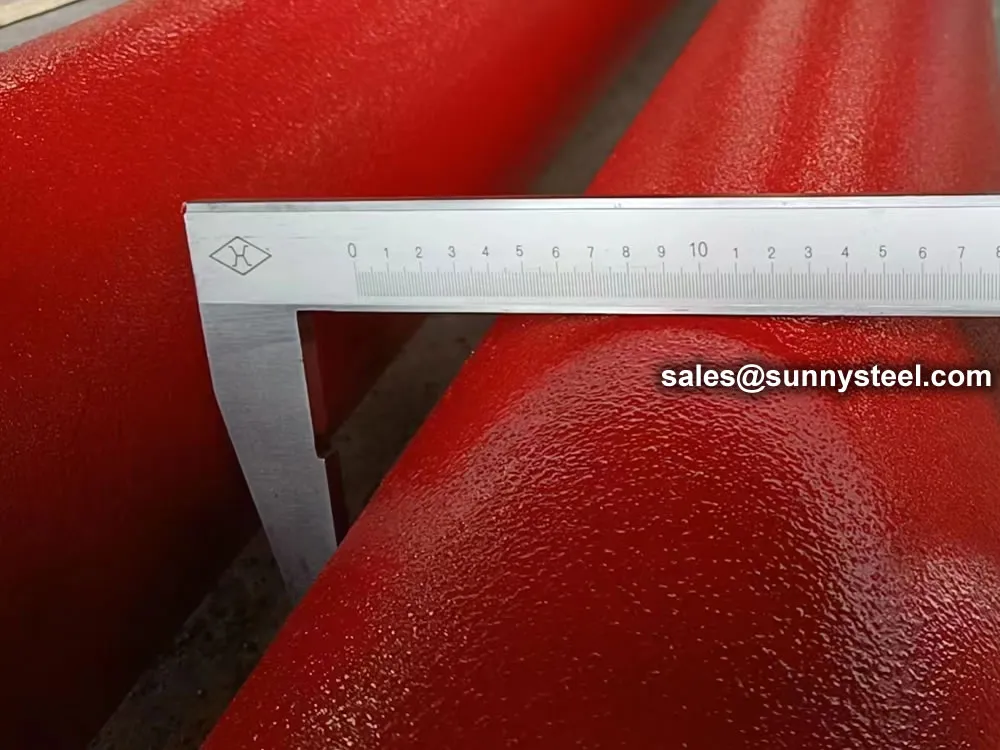

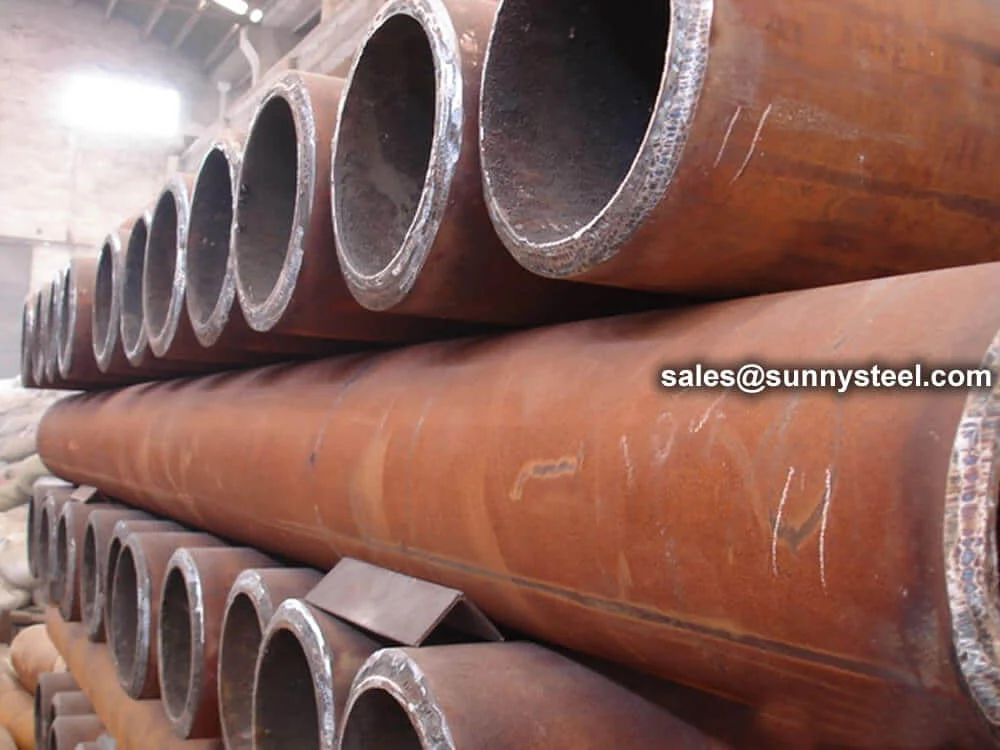

The pipe’s seamless cast structure ensures uniform wall thickness and excellent pressure resistance. The inner wall can be precision-machined or heat-treated for better flow efficiency and resistance to scaling or buildup.

Also known as rare earth alloy wear pipe, abrasion-resistant casting tube, or high-strength alloy cast pipe, this product dramatically extends pipeline life, reduces maintenance frequency, and minimizes system downtime in aggressive processing environments.

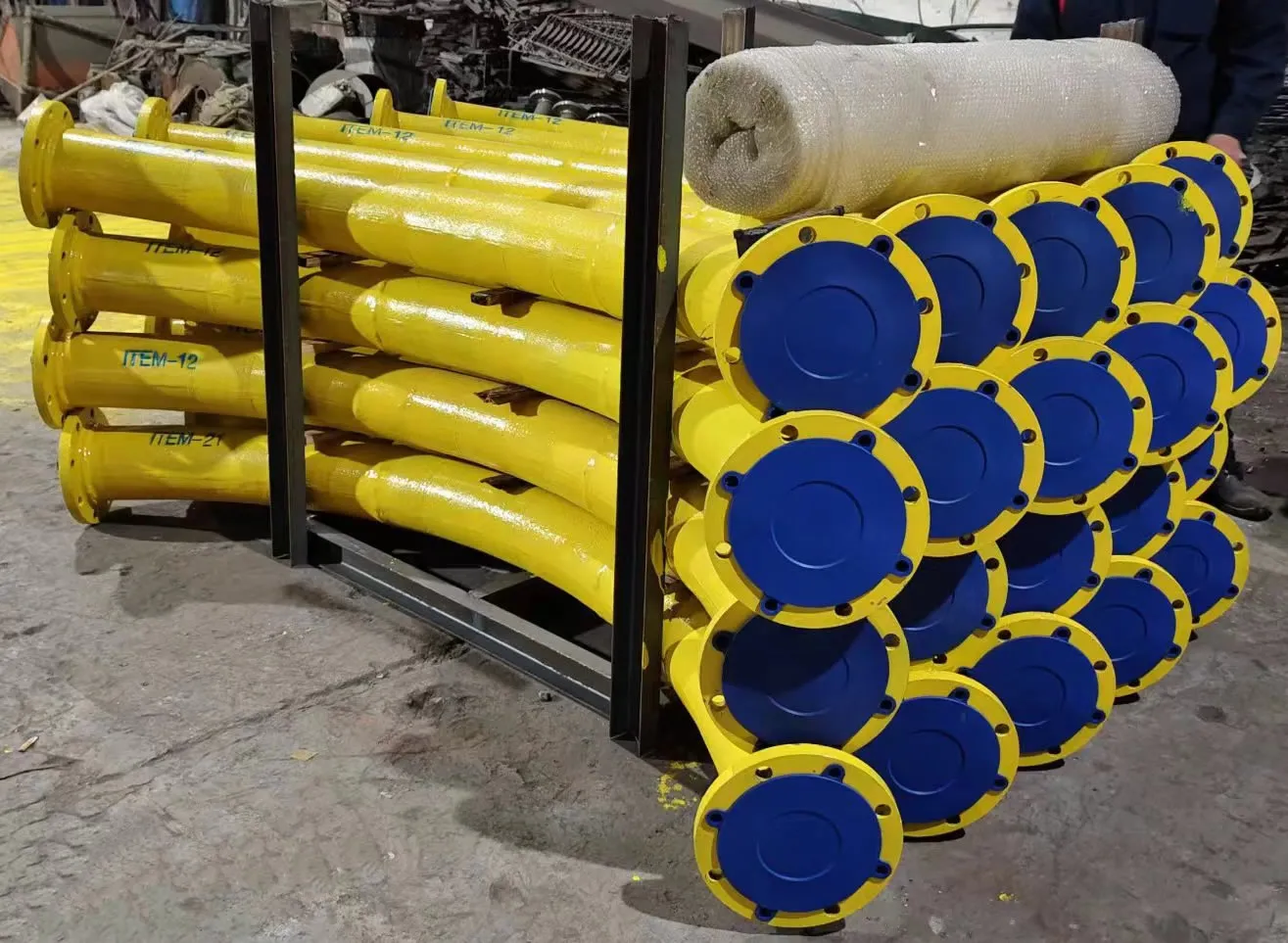

Sunny Steel offers a full range of diameters, wall thicknesses, lengths, and connection types (flanged, grooved, welded) for rare earth alloy wear resisting casting pipes, along with material certification, design consultation, and international logistics support.