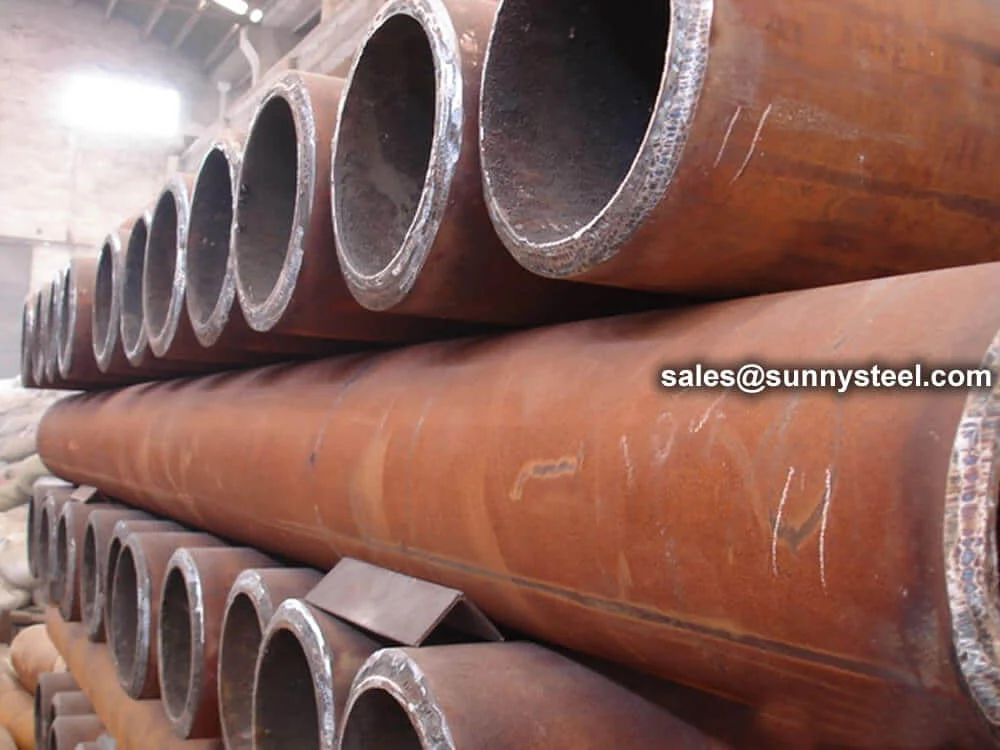

The Rare Earth Alloy Wear Resistant Pulverized Coal Mixer is engineered for the rigorous demands of pulverized coal handling systems in thermal power plants and industrial processing. Manufactured from high-strength alloy steel infused with rare earth elements such as cerium and lanthanum, this mixer offers outstanding wear resistance, impact toughness, and corrosion protection.

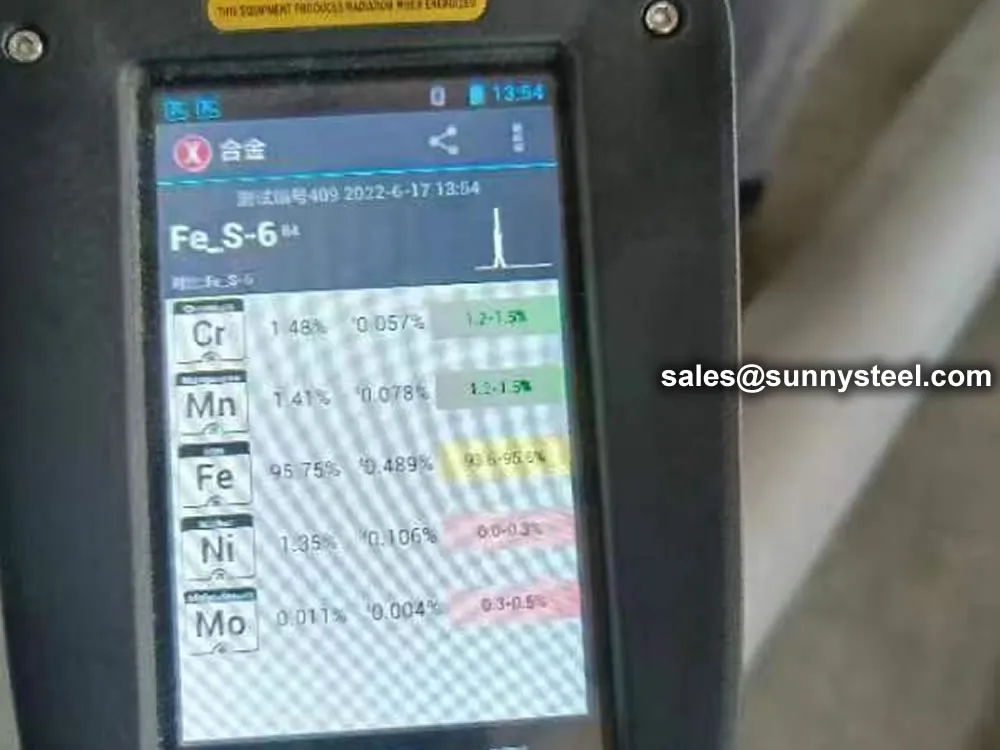

The rare earth alloy composition enhances the microstructure, resulting in refined grain size, increased hardness (typically 240–320 HB), and improved resistance to erosion and mechanical shock from high-speed coal particles. This extends the mixer’s operational life and reduces maintenance costs.

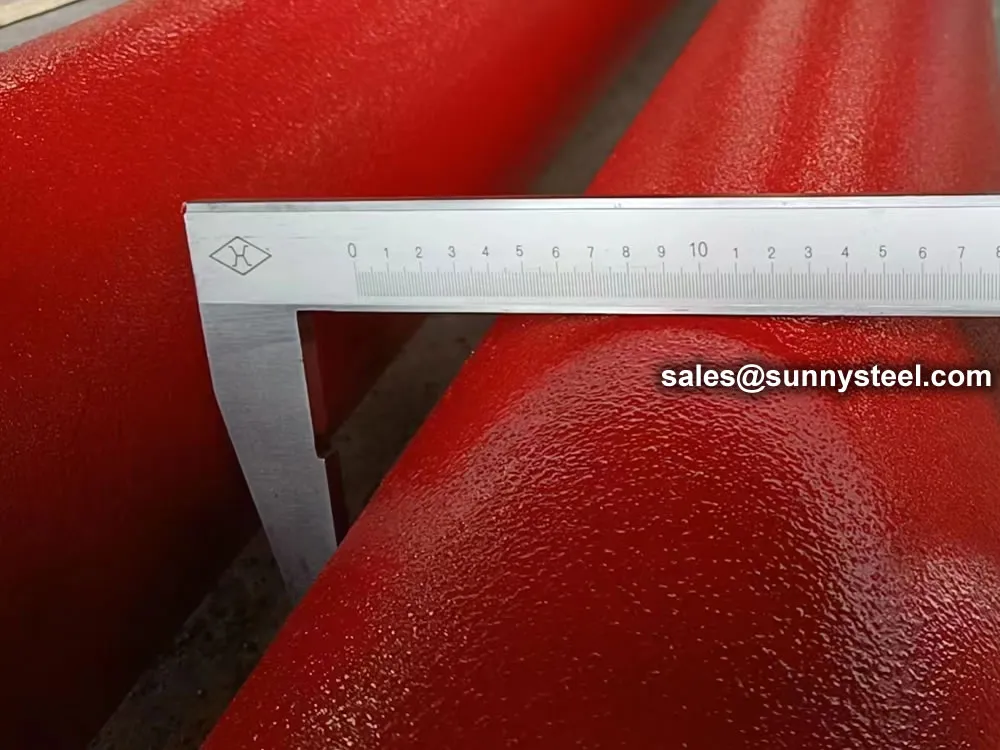

Designed to handle highly abrasive pulverized coal powder and ash mixtures, the mixer ensures thorough blending and uniform consistency while withstanding harsh operating conditions including high temperature and cyclic stresses. Its robust construction prevents premature failure common with standard steel mixers exposed to coal dust abrasion.

Widely used in coal-fired power plants, cement factories, and other industries requiring durable pulverized coal processing equipment, this mixer contributes to improved fuel preparation and combustion efficiency.

Also known as rare earth wear resistant coal mixer, abrasion resistant pulverized coal blender, or alloy steel coal mixing equipment, it is a critical component for reliable and efficient coal handling systems.

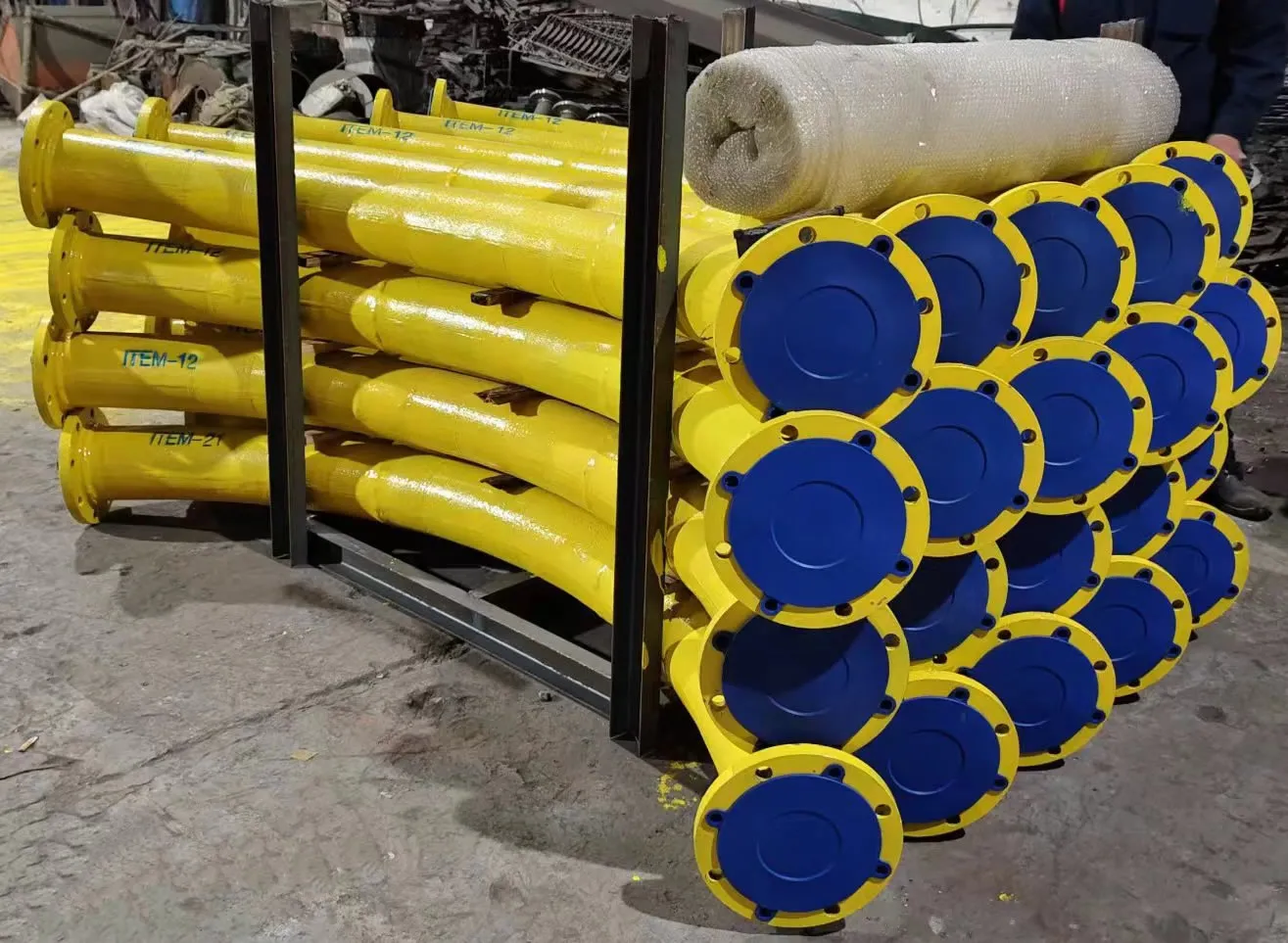

Sunny Steel offers customized designs, sizes, and technical support for rare earth alloy pulverized coal mixers to meet specific plant requirements, along with quality assurance and worldwide delivery.