Material

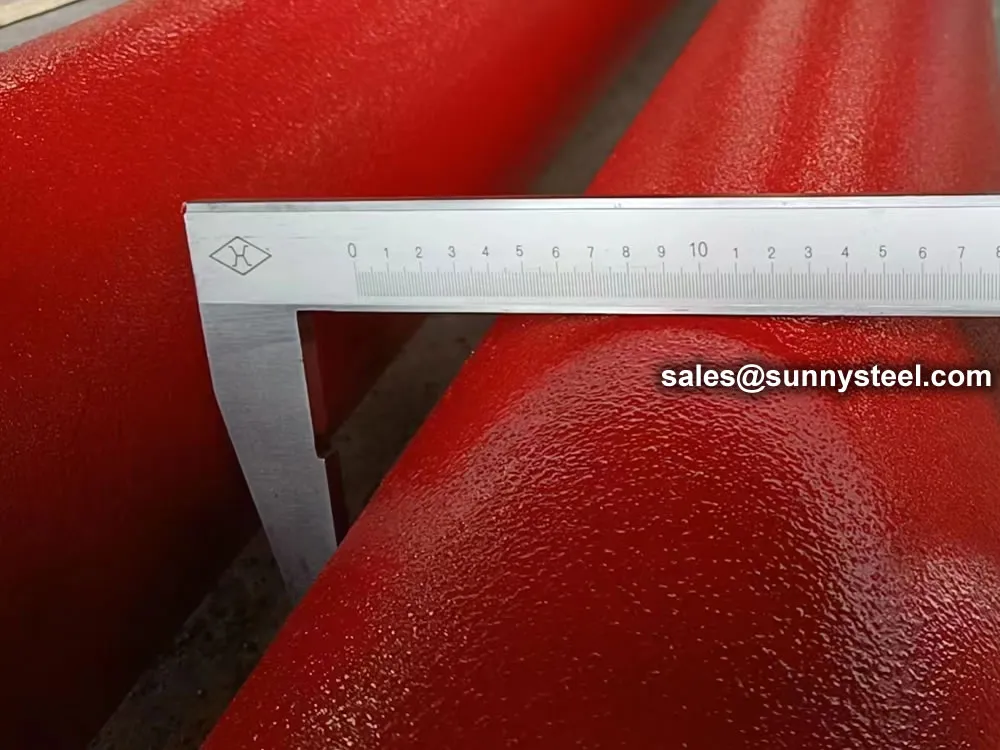

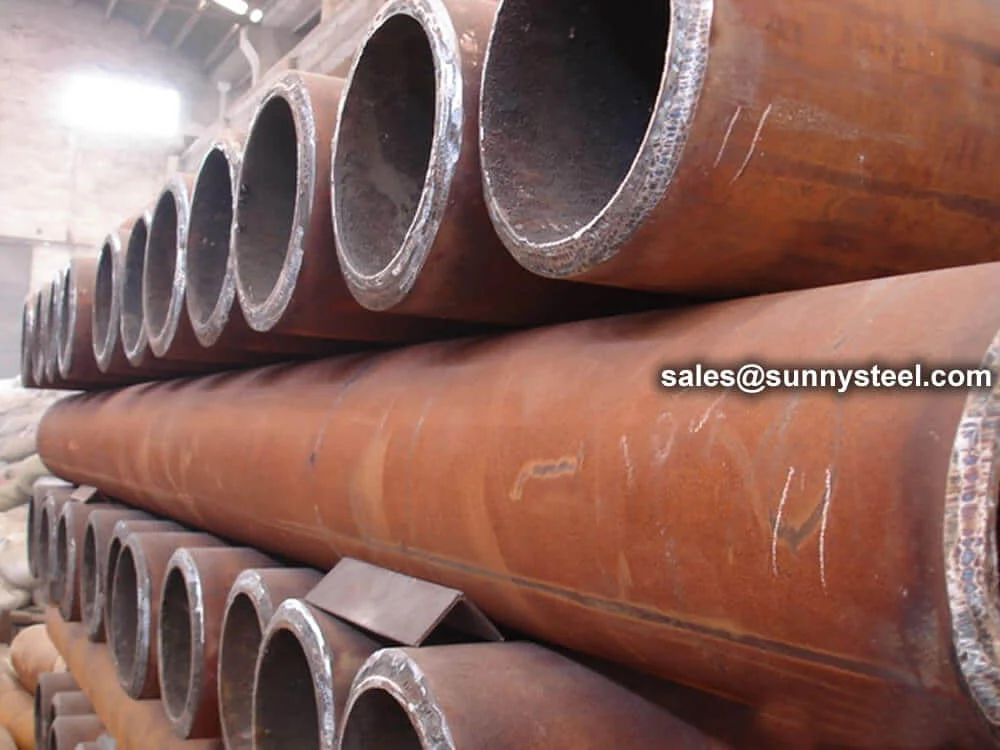

Ceramic-lined pipes are known for their high hardness, wear

resistance, thermal stability, and self-lubricating

performance.

Made from rare earth alloy steel and high-purity alumina ceramics, they offer superior performance

in abrasive and high-temperature environments.

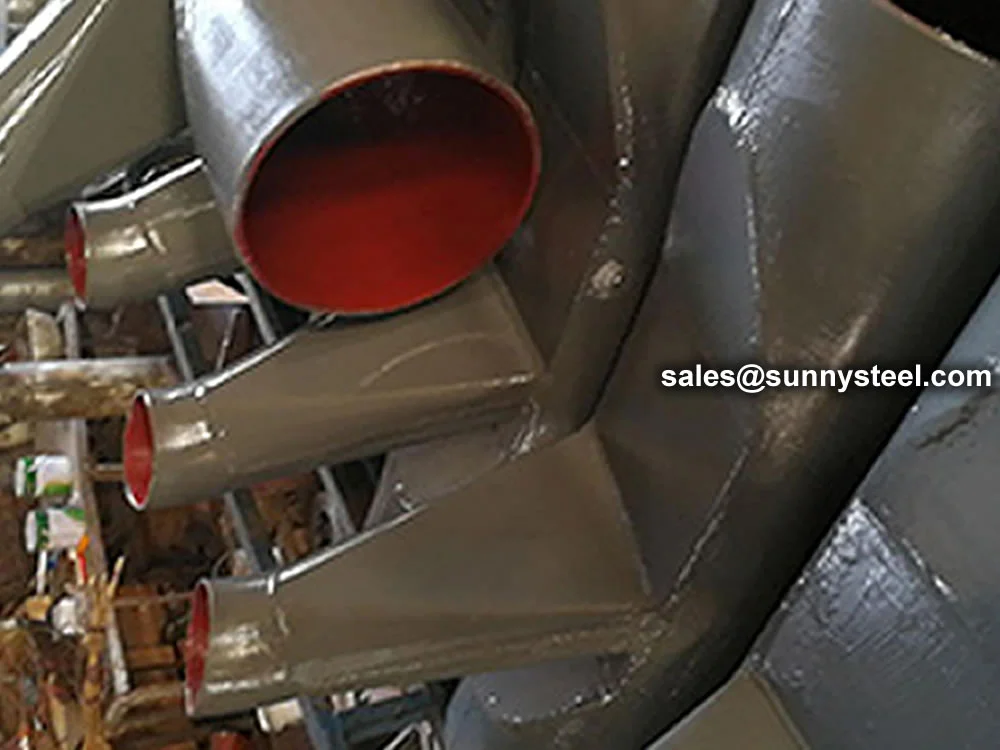

Ceramic-lined pipes are reinforced with anti-shedding alumina tiles, strong inorganic adhesives, and

precision welding. This dual-layer structure ensures long-term performance under high-stress,

corrosive, and abrasive conditions.

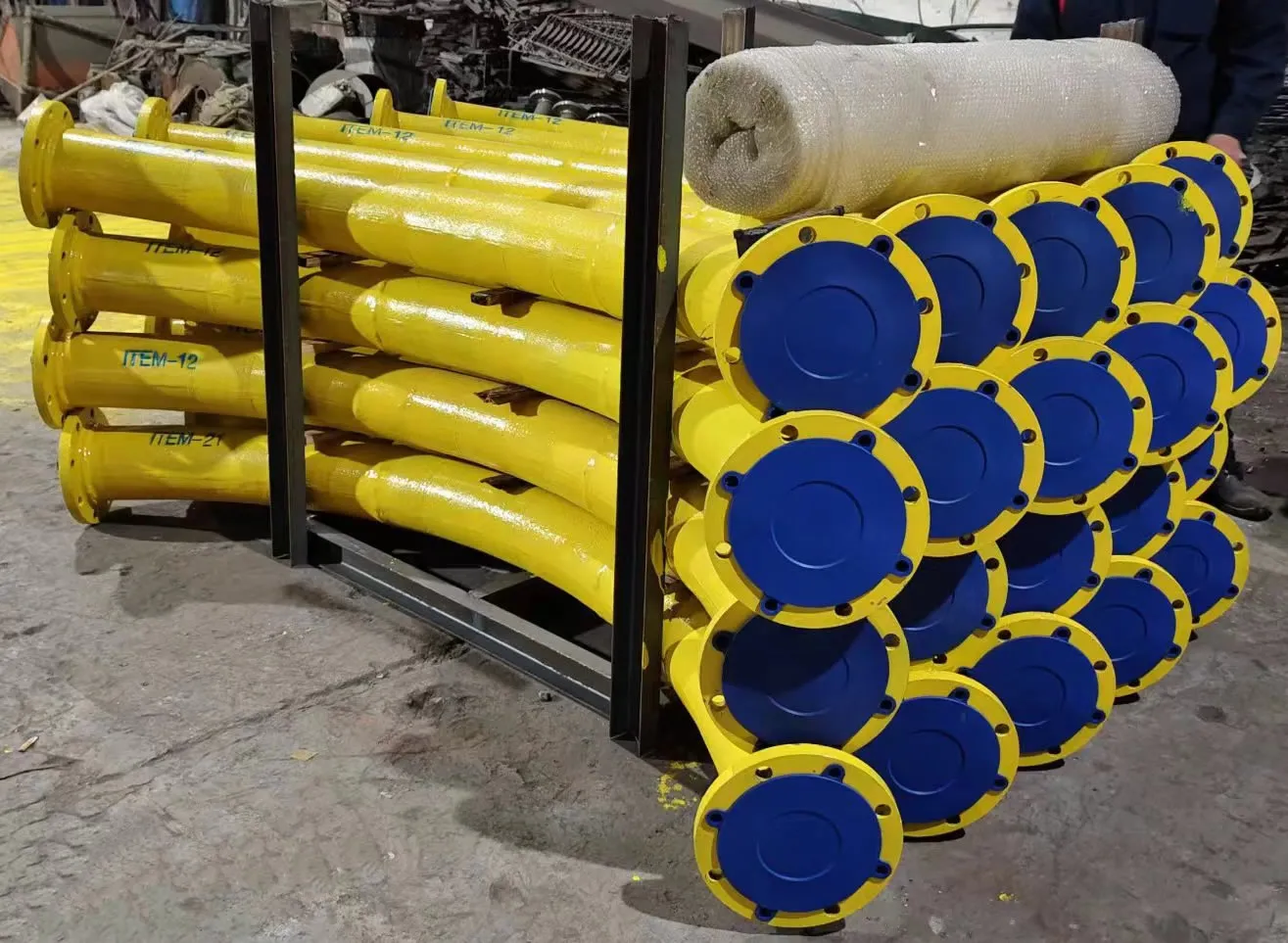

These pipes are designed for flexible installation, low

maintenance, and cost-effectiveness, making them ideal for use in

mining, thermal power plants, steelworks, and chemical industries.

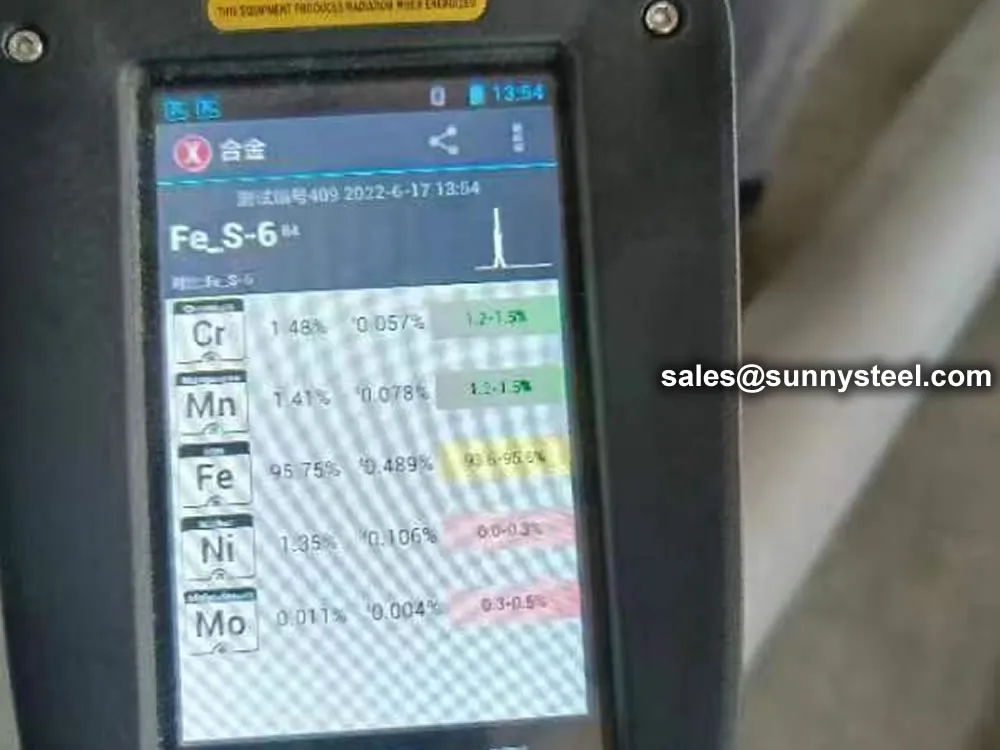

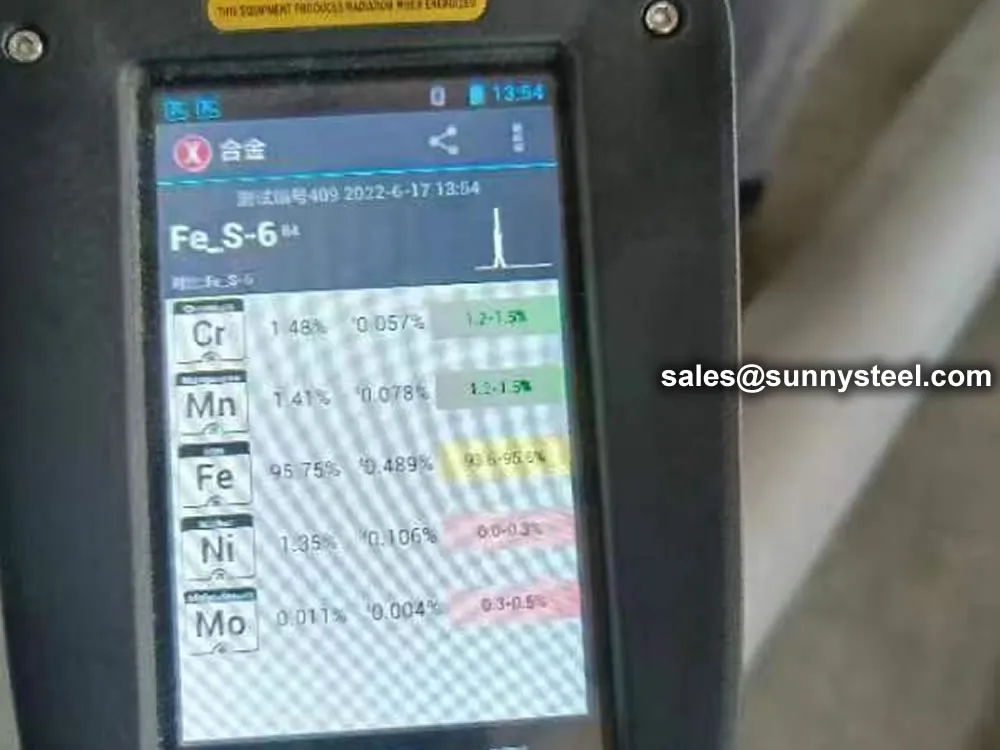

PMI Test

High Hardness

Rockwell hardness of alumina ceramics reaches HRA80–90, second only to diamond and much

higher than wear-resistant steel.

Wear Resistance

Alumina ceramics provide 266× the wear life of manganese steel and over 170× that of high

chromium cast iron.

Thermal Stability

Withstands continuous service temperatures up to 1400°C, making it suitable for furnaces and

kilns.

Low Friction

Smooth surface reduces flow resistance; surface roughness is 1/6 that of steel pipes.

Custom Shapes

Supports thick-walled, curved, and shaped designs to match various piping systems and wear

zones.

Lightweight

With a density of ~3.6g/cm³, alumina ceramic pipes weigh half as much as steel, improving

transport and installation efficiency.

ZG40CrMnMoNiSiRe Alloy Steel

This rare earth alloy steel contains chromium, molybdenum, nickel, and rare earth elements to enhance

strength, toughness, and corrosion resistance.

Commonly used in boiler tubes, heat exchangers, and high-pressure

pipelines, it withstands creep, corrosion, and thermal cycling in extreme service conditions.

While offering excellent performance, its specialized composition makes it better suited for

heavy-duty applications rather than general use.