Technology

High chromium cast iron represents the third generation of white cast iron, evolved from ordinary white cast iron and hard nickel cast iron.

Superior Wear Resistant Composite Pipe

Bimetallic lined high chrome alloy pipe features a hard, wear-resistant high chromium alloy inner layer bonded to a tough steel outer pipe, offering excellent durability in abrasive industrial environments.

Superior Wear Resistant Composite Pipe

Bimetallic lined high chrome alloy pipe features a hard, wear-resistant high chromium alloy inner layer bonded to a tough steel outer pipe, offering excellent durability in abrasive industrial environments.

Inner Liner Thickness Range

Maximum Operating Temperature

Maximum Pressure Rating

Extended Service Life

Bimetal clad pipes combine the strength of carbon steel with the corrosion resistance of alloy linings, offering superior performance in harsh industrial environments.

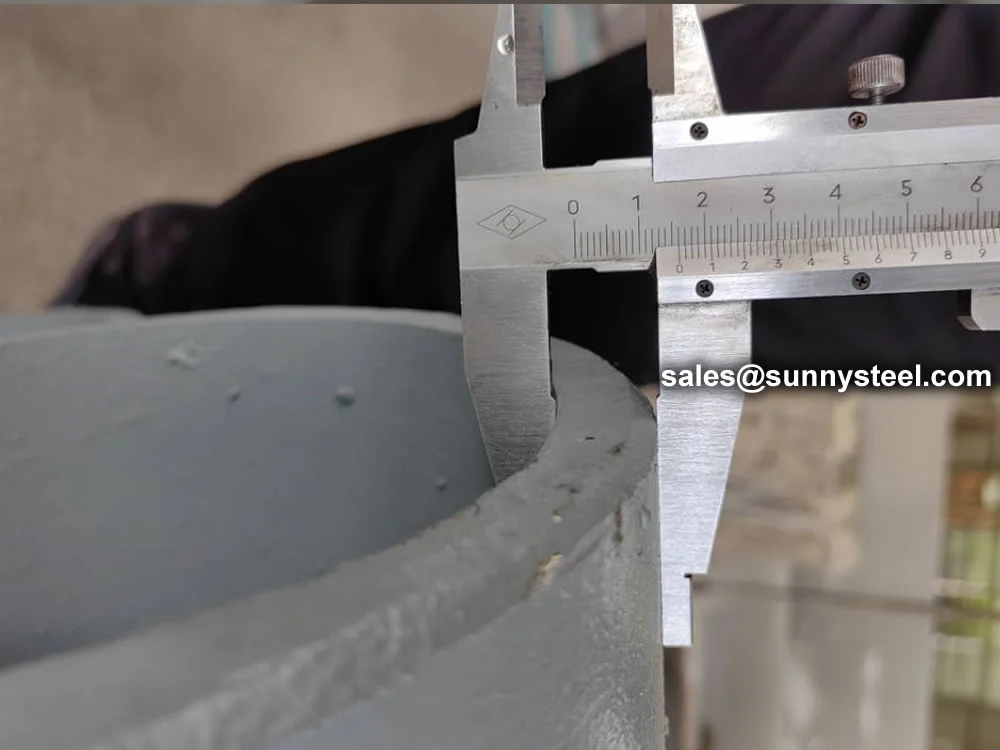

A bimetal clad pipe is a composite pipe structure with an outer carbon steel shell and an inner corrosion-resistant alloy liner, typically ranging from 0.5 to 3mm in thickness. The outer pipe provides mechanical strength and pressure resistance, while the inner liner directly resists chemical corrosion caused by mediums such as CO2, H2S, and chlorides. This combination ensures excellent structural integrity with significantly reduced material costs compared to solid alloy pipes.

Alloy inner liner protects against harsh chemicals, acids, and seawater, extending pipeline life significantly.

Carbon steel outer pipe withstands high pressures up to 35 MPa, ensuring structural durability in critical applications.

Up to 70% lower material costs than solid alloy pipes with 5–10x the lifespan of traditional steel piping.

The super-hard alloy liner has a hardness above HRC 56, ensuring excellent durability under abrasive conditions.

The metallurgically bonded dual-layer structure withstands expansion, contraction, and mechanical shock without cracking.

Ideal for both wet and dry environments, the alloy matrix resists chemical corrosion and thermal degradation.

Manufactured using EPC (lost foam casting), ensuring uniform wall thickness, high compactness, and stable quality.

Compatible with flange, quick coupling, or direct welding. Easy to cut, reassemble, and maintain on-site.

Delivers 5–10× longer service life at a lower cost than solid alloy pipes, offering significant savings over time.

High chromium cast iron represents the third generation of white cast iron, evolved from ordinary white cast iron and hard nickel cast iron.

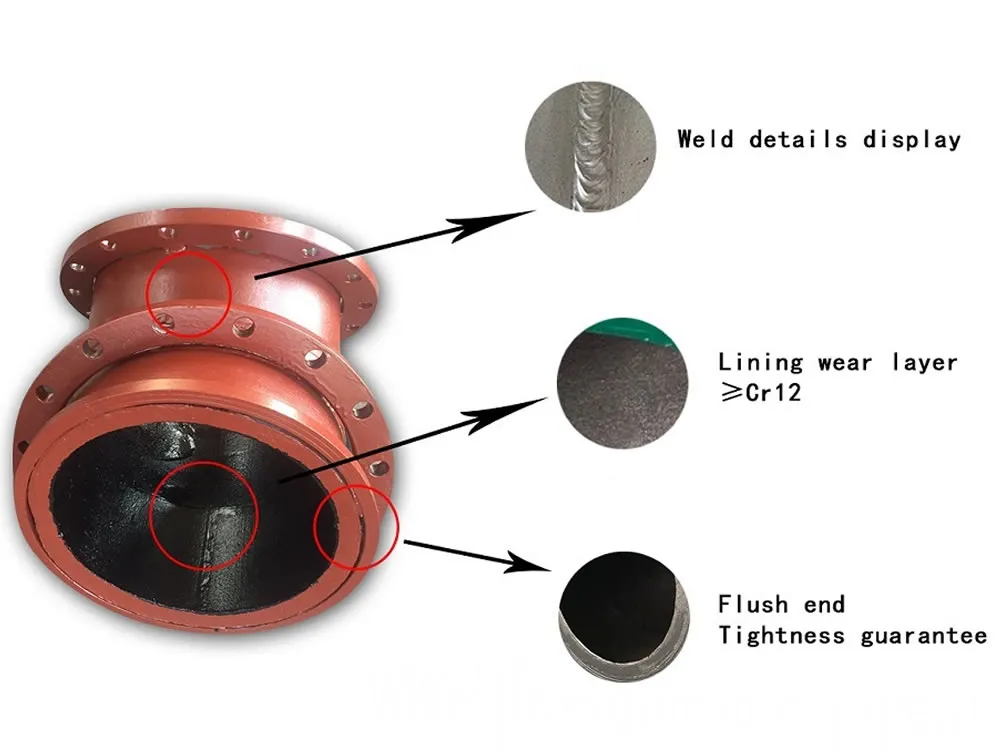

The wear-resistant elbow is fabricated using a bimetal wear-resistant composite. Its production mainly employs a combination of vacuum absorption casting with a lost foam mold process, supplemented by other specified manufacturing techniques. The wear-resistant layer is made from composite alloy steel, with each elbow featuring an eccentric compound design. To enhance durability, the outer section of the elbow is thickened based on operational conditions to balance the lifespan between the inner and outer surfaces.

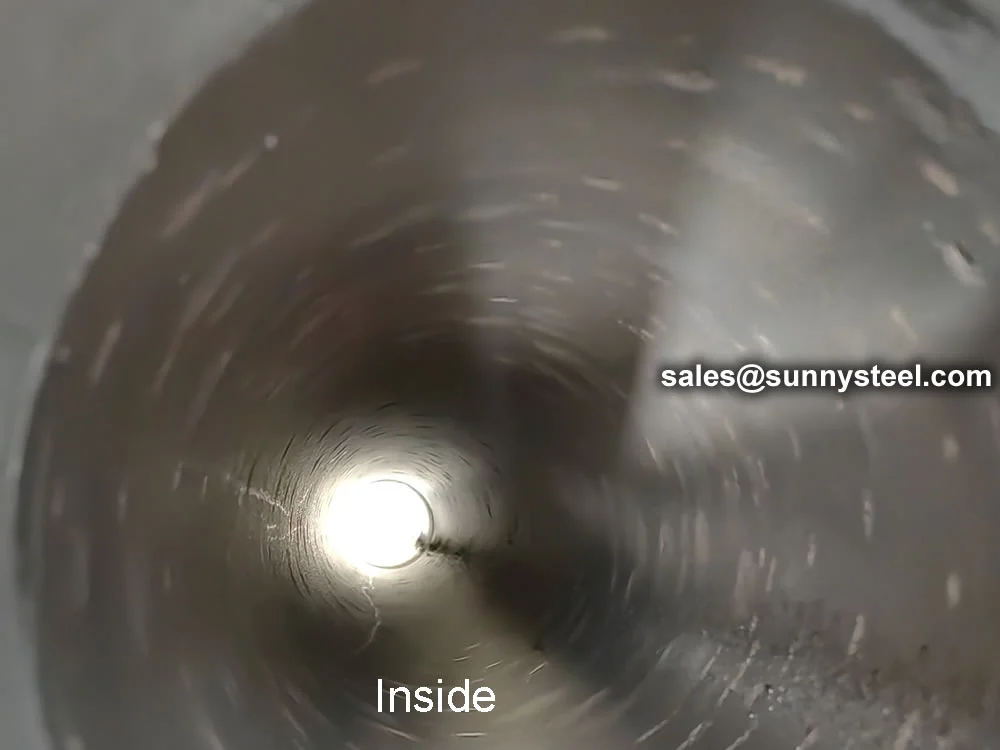

To reduce resistance in coal powder transportation, the elbow’s inner surface must be smooth and streamlined, prohibiting the use of “shrimp waist” welding methods. This ensures the inner diameter remains consistent at 510 mm throughout, without any protrusions or platforms.

The wear-resistant lining consists of a high chromium alloy (minimum grade KMTBCr28), offering a service life exceeding two years and annual wear less than 5 mm. The outer lining thickness is 28 mm, and the inner lining thickness is 22 mm, both with hardness above HRC 55. The outer pipe dimensions for the lining section are 558×10 mm, connecting pipe 508×10 mm, and outer ring 558×22 mm, made from 10 steel. Seamless or welded pipes may be used, complying with standards GB2087 and GB8163.

The bimetal wear-resistant tube’s inner wall made of KMTBCr28 alloy has stable quality and excellent comprehensive performance. Addition of rare earth elements improves alloy quality by refining grain structure and forming a protective surface film. Molybdenum is added to provide antioxidation properties and enhance high-temperature service life. Boron carbide can also be incorporated to control hardness between HRC 45 and 65, resolving the typical hardness versus weldability tradeoff in wear-resistant steel.

Pipe lining is a mechanical process used to bond a protective material inside a pipe, often for restoration or life extension. Benefits include:

Pipe cladding is a metallurgical process where corrosion- or wear-resistant materials are bonded to the pipe body. Common purposes include:

Bimetal clad pipes are widely used in high-corrosion, high-pressure, and wear-resistant environments across multiple industries.

Used as casing pipes for offshore oil & gas with Inconel or Duplex liners and carbon steel outer layers.

High-temp resistant cladding materials like Alloy 800 and 17-14CuMo ensure durability under 800°C and 35 MPa conditions.

Clad pipes with corrosion-resistant alloys like Sanicro 65 extend the service life in corrosive incineration environments.

Used in chemical and power industries, combining high thermal conductivity with excellent corrosion resistance.

Ideal for pneumatic conveying of fine powders with SUS316L or Stellite alloy liners providing long service life.

Nickel, titanium, and copper alloys used as liners ensure performance in desalination and seawater cooling systems.

Industrial axial fans offer high-efficiency airflo...

Stainless carbon steel composite pipe features a c...

Bimetallic composite pipe features a high-hardness...

Bimetallic composite pipe tee combines a hard, wea...