Astm A532 Casting

High Chrome Wear Resistant Casting Components

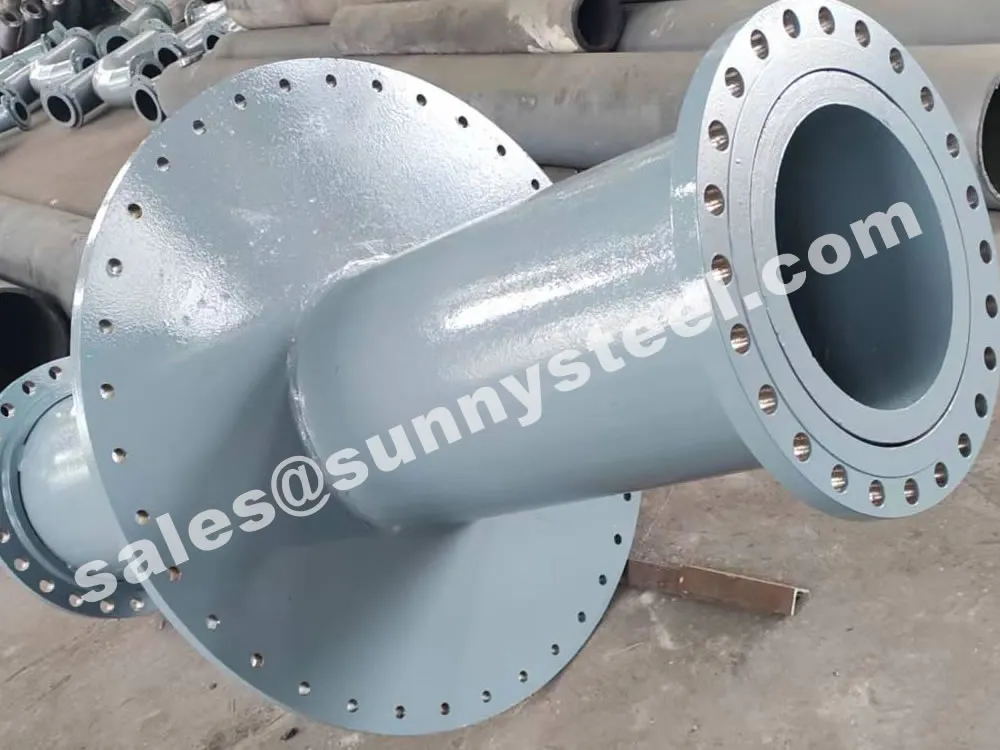

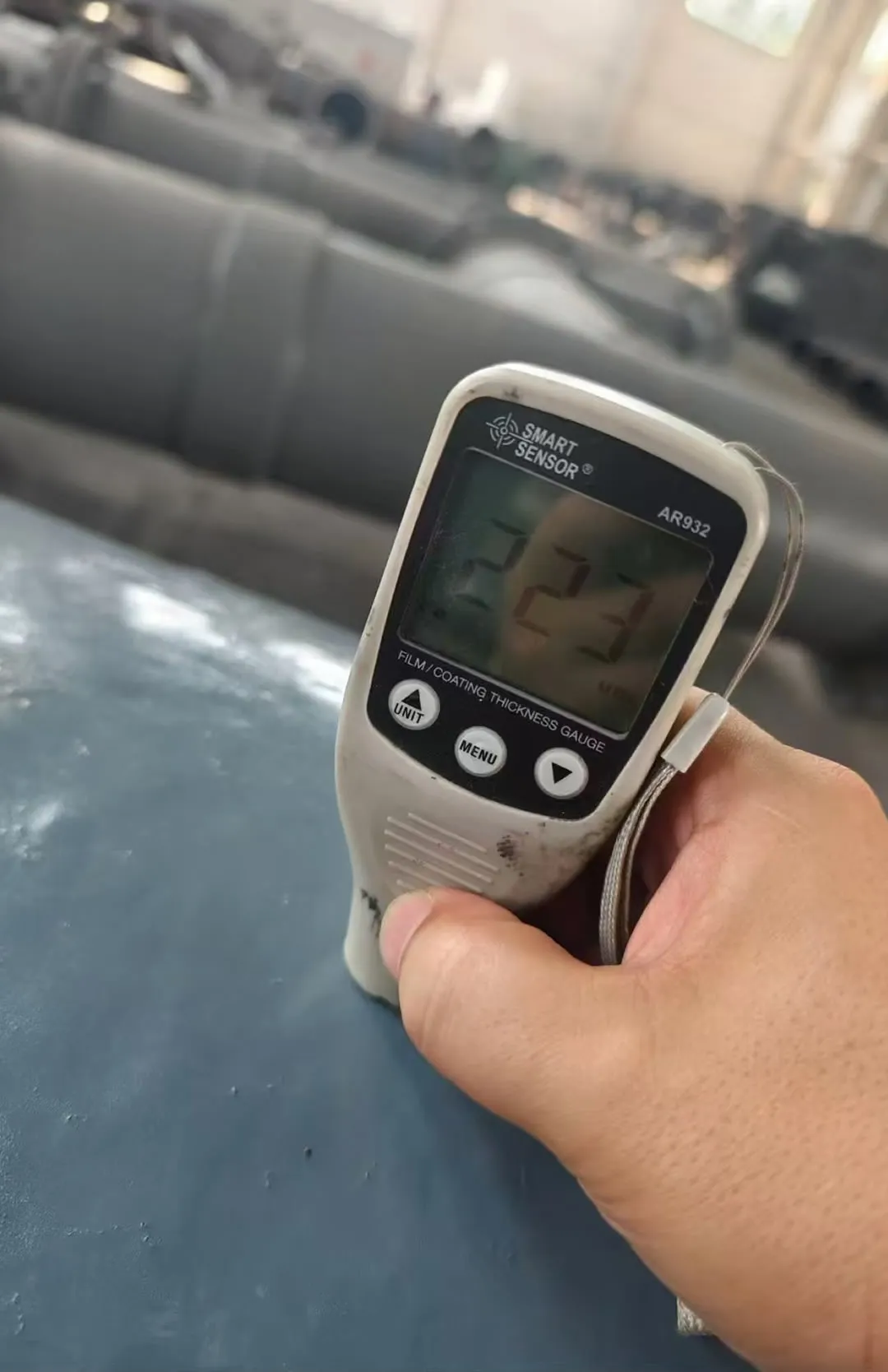

Astm a532 high chromium castings deliver outstanding wear resistance and hardness, ideal for mining, cement, power, and material handling industries.

Astm A532 Casting

High Chrome Wear Resistant Casting Components

Astm a532 high chromium castings deliver outstanding wear resistance and hardness, ideal for mining, cement, power, and material handling industries.