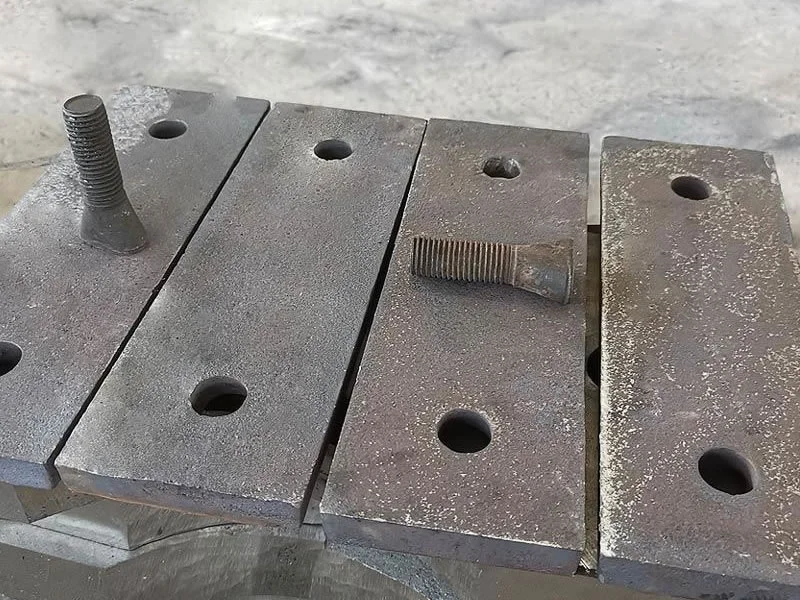

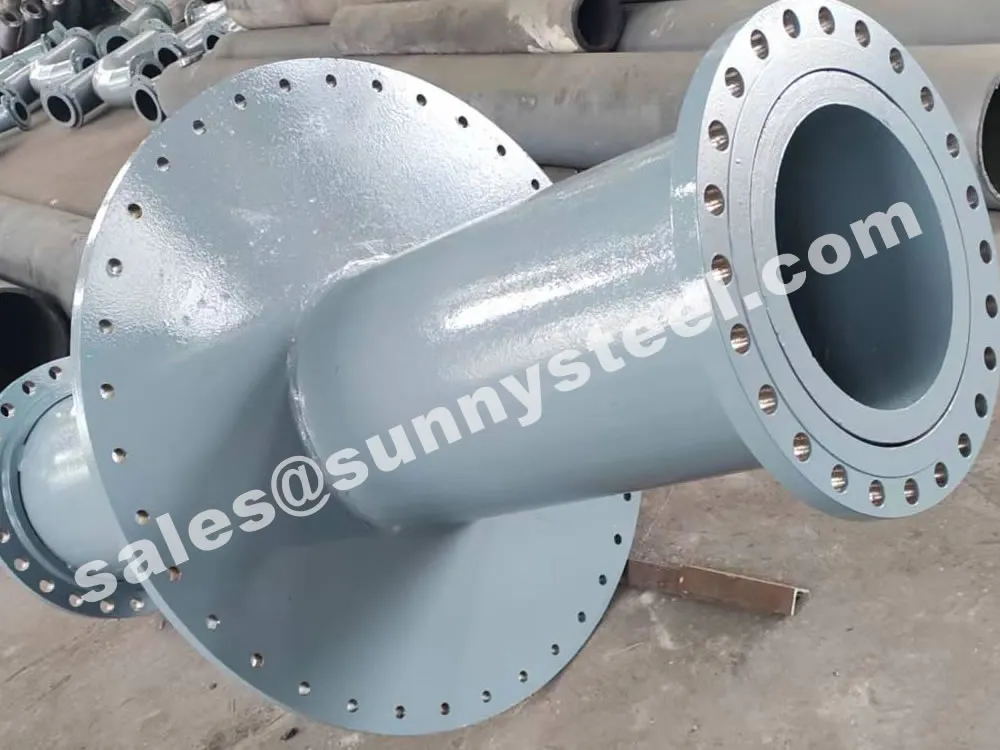

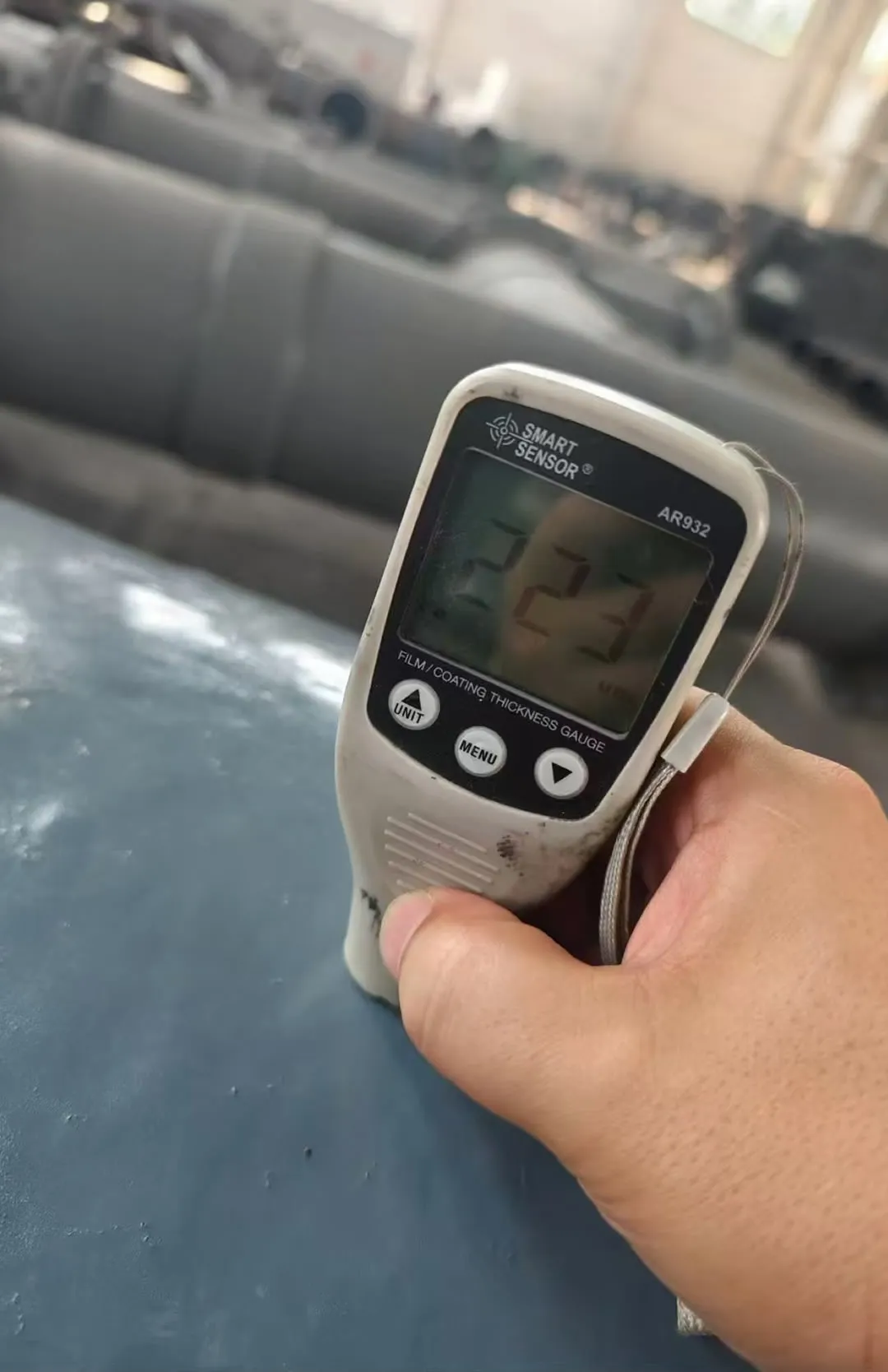

Ni-Hard Cast Iron Wear Plates

Premium-grade Ni-hard Cast Iron Plates Offering Superior Abrasion Resistance And Extended Service Life In Extreme Wear Environments.

Ni-hard cast iron wear plates are engineered for high-abrasion, moderate-impact conditions, providing excellent hardness, longevity, and cost-efficiency.

Ni-Hard Cast Iron Wear Plates

Premium-grade Ni-hard Cast Iron Plates Offering Superior Abrasion Resistance And Extended Service Life In Extreme Wear Environments.

Ni-hard cast iron wear plates are engineered for high-abrasion, moderate-impact conditions, providing excellent hardness, longevity, and cost-efficiency.