What is UHMWPE?

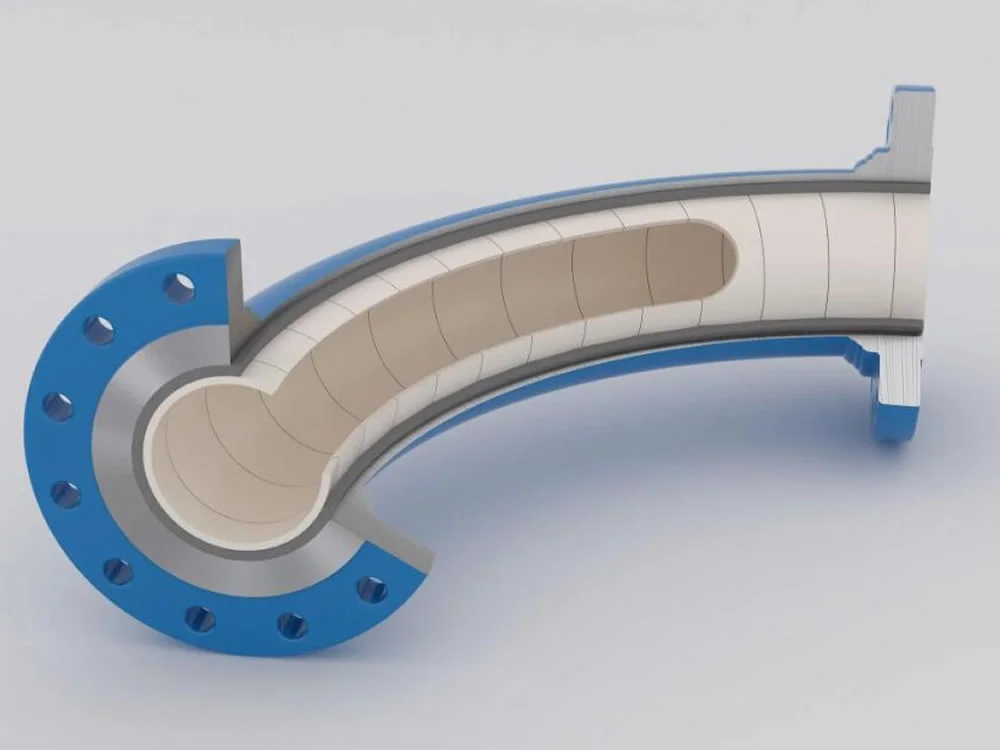

Ultra-high molecular weight polyethylene pipe has superior performance over conventional HDPE pipe such as very high wear resistance, impact resistance, excellent resistance to internal pressure strength, resistance to environmental stress cracking, intrinsically self-lubricating, anti-adhesion, low temperature resistance and excellent chemical resistance.

With a molecular weight typically between 3.5 and 9.2 million g/mol, UHMWPE exhibits superior wear resistance, impact strength, and chemical stability, far exceeding conventional polyethylene or metal pipes in durability and performance.