UHMWPE (Ultra-High Molecular Weight Polyethylene) dredging pipes offer exceptional abrasion resistance, corrosion protection, and flexibility for marine and slurry transport applications.

UHMWPE Dredging Pipes are manufactured using Ultra-High Molecular Weight Polyethylene, a high-performance polymer known for its exceptional wear resistance, chemical inertness, low friction, and impact toughness. These characteristics make UHMWPE pipes a top choice for transporting abrasive media such as sand, silt, mud, and gravel in dredging, mining, and marine construction projects.

Unlike traditional steel or rubber hoses, UHMWPE dredging pipes are lightweight and floatable, often used in combination with floating collars or pontoons, reducing the need for complex supports. Their low friction coefficient reduces energy consumption during pumping, and their flexibility allows for easy installation in curved or shifting marine terrains.

The high density and molecular weight (≥2 million g/mol) give UHMWPE excellent performance against abrasion and saltwater corrosion, even under continuous heavy-duty operations. It is widely used in port expansion, land reclamation, river dredging, and coastal sediment pumping.

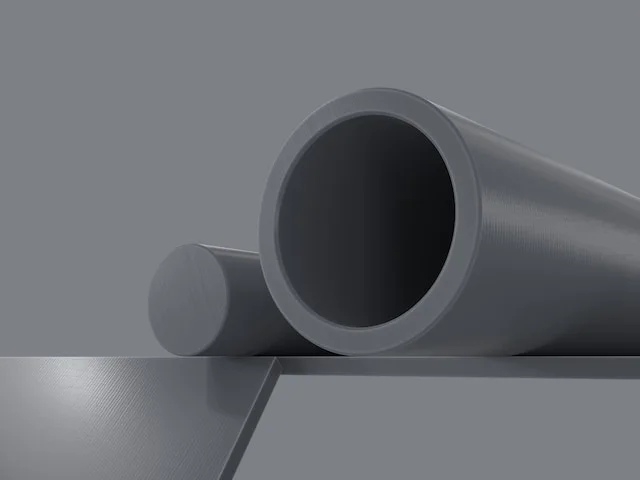

UHMWPE pipes are available in various diameters and wall thicknesses, making them suitable for a range of applications. Whether you're transporting coarse sand, fine silt, gravel, or mud, UHMWPE pipes can provide long-term durability and performance, enhanced by their ability to withstand extreme conditions and adapt to changing marine environments.

The high density and molecular weight (≥2 million g/mol) give UHMWPE excellent performance against abrasion and saltwater corrosion, even under continuous heavy-duty operations. It is widely used in port expansion, land reclamation, river dredging, and coastal sediment pumping.

Material Features

- Molecular weight: 3–6 million g/mol

- Abrasion resistance: 15× greater than steel

- Friction coefficient: 5× lower than steel

- Impact strength: 5× stronger than HDPE

- Service life: 3× longer than steel pipes

Structural Parameters

- Diameter range: 20mm – 1200mm

- Wall thickness: Up to 65mm

- Weight: ~1/8 of steel

- Bending radius: Up to 30× pipe OD

- Single-layer or steel-reinforced options

Typical Applications

- Harbor and coastal dredging

- Mining slurry transport

- Chemical fluid handling

- Wastewater treatment

- Riverbed and seabed reclamation

- Floating marine pipeline systems

Performance Advantages

- Leak-free and anti-scaling surface ensures smooth flow

- Inert to seawater, acids, alkalis, and solvents

- Customizable connections: flanged, welded, floating

- Reduces installation time and equipment costs

- Eco-friendly with lower energy and pumping costs

Compared to traditional HDPE or steel pipes, UHMWPE dredging pipes outperform in flexibility, lifespan, and chemical resistance, making them the ideal solution for challenging environments and modern dredging operations.