UHMWPE life escape pipes, constructed from ultra-high molecular weight polyethylene with a molecular weight exceeding 1.5 million g/mol, are specialized pipelines designed for emergency evacuation systems in underground mining and other high-risk environments. These pipes are engineered to provide a safe, reliable, and durable conduit for workers to escape hazardous conditions, such as mine collapses, gas leaks, or flooding. The exceptional properties of UHMWPE—including unparalleled wear resistance, high impact strength, and corrosion resistance—make these pipes an ideal choice for critical safety applications in demanding settings.

The UHMWPE life escape pipe offers wear resistance 4-7 times greater than Q235 steel and 2.7 times that of 16Mn wear-resistant steel, ensuring longevity even in abrasive underground conditions. Its impact resistance is remarkable, being five times that of HDPE, two times that of PC pipes, and ten times that of PTFE pipes, allowing it to withstand significant mechanical stress without cracking or deforming. With an elongation of no less than 350%, the pipe remains flexible and resistant to cracking during ground settling or seismic activity, ensuring uninterrupted functionality in dynamic environments like mine subsidence zones.

The pipe’s low friction coefficient (0.009 compared to 0.013 for steel) and self-lubricating, non-adhesive properties prevent blockages from debris or sediment, maintaining clear passageways for evacuation. This smoothness also enhances airflow efficiency, critical for ventilation in confined spaces. Additionally, UHMWPE’s chemical stability ensures resistance to corrosive substances like acids, alkalis, and organic solvents, making it suitable for harsh mining environments where exposure to chemicals or groundwater is common. The material’s non-toxic, hygienic properties further ensure safety for human use in emergency scenarios.

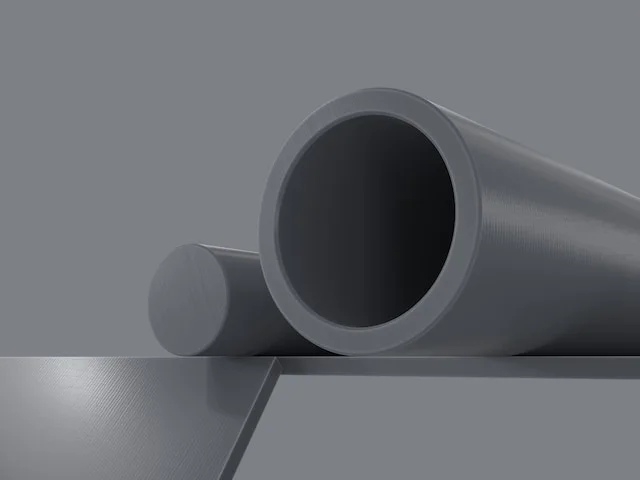

Available in custom sizes ranging from 50mm to 1200mm outer diameter and up to 65mm wall thickness, UHMWPE life escape pipes can be tailored to specific project requirements, with options for flanged or welded connections for secure installation. Their lightweight design—approximately one-eighth the weight of steel—facilitates easy transport and installation in underground tunnels, reducing labor costs and setup time. The pipes’ flexibility and high tensile strength allow them to adapt to complex tunnel layouts and withstand external forces, such as water hammer impacts or geological shifts, without compromising structural integrity.

In mining applications, UHMWPE life escape pipes outperform traditional materials like steel or HDPE, which are prone to corrosion, scaling, or wear. Their service life is over three times that of steel pipes, significantly reducing maintenance and replacement costs. Unlike conventional pipelines with high leakage rates (15-30% in PCCP or cast iron systems), UHMWPE pipes are leak-free, ensuring reliable performance during emergencies. Their resistance to low temperatures (down to -169°C) and aging (over 50 years under natural light) further enhances their suitability for long-term use in underground environments.

Beyond mining, these pipes are used in other high-risk settings, such as chemical plants or industrial facilities requiring emergency evacuation systems. Their eco-friendly design, with no need for rust-proofing or frequent maintenance, reduces operational costs by up to 95% compared to traditional pipelines, making them a cost-effective and sustainable solution. For inquiries or custom orders, contact Shandong Buoy and Pipe Industry Co., Ltd. at their official website.