UHMWPE food pipe, crafted from ultra-high molecular weight polyethylene with a molecular weight exceeding 1.5 million g/mol, is a specialized pipeline designed for the safe and hygienic transport of food, beverages, and other consumable materials in food processing and related industries. Certified as food-grade and compliant with FDA and USDA standards, these pipes offer exceptional wear resistance, corrosion resistance, and non-toxic properties, making them an ideal choice for applications requiring stringent hygiene and safety standards, such as dairy, beverage, grain, and edible oil transport.

The UHMWPE food pipe boasts wear resistance 4-7 times greater than Q235 steel and 2.7 times that of 16Mn wear-resistant steel, ensuring durability even when transporting abrasive food materials like grains or slurries. Its impact resistance is five times that of HDPE, two times that of PC pipes, and ten times that of PTFE, allowing it to withstand mechanical stresses without cracking. The pipe’s low friction coefficient (0.009 compared to 0.013 for steel) and self-lubricating, non-adhesive properties prevent material buildup, ensuring smooth flow and reducing the risk of contamination. This smoothness, with a roughness of 0.00022, minimizes scaling and eliminates the need for acid cleaning, saving significant maintenance costs.

UHMWPE’s chemical stability ensures resistance to acids, alkalis, and organic solvents, making it suitable for handling a wide range of food-related substances, including acidic juices or corrosive cleaning agents used in food processing plants. Its non-toxic and hygienic properties prevent bacterial growth and ensure no harmful substances leach into the transported materials, meeting strict regulatory requirements for food safety. The pipe’s high toughness, with an elongation of no less than 350%, allows it to remain flexible and crack-resistant under dynamic conditions, such as vibrations or pressure changes in processing systems.

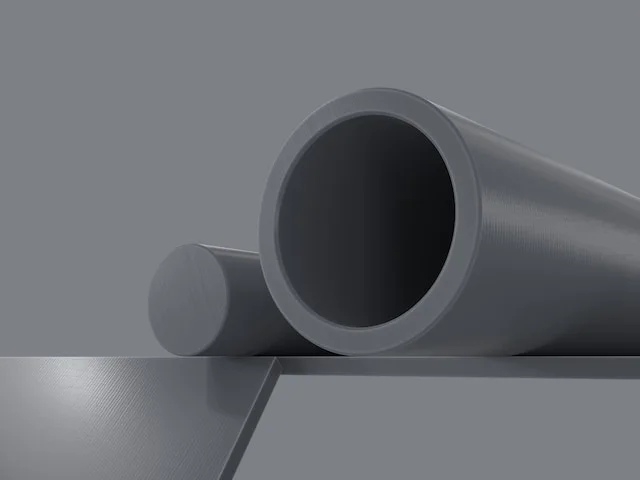

Available in custom diameters from 50mm to 1200mm and wall thicknesses up to 65mm, UHMWPE food pipes can be tailored to specific processing needs, with options for flanged or welded connections for secure, leak-free installation. Their lightweight design—approximately one-eighth the weight of steel—simplifies handling and reduces installation costs compared to traditional metal pipes. The pipes’ ability to operate in a broad temperature range (down to -169°C and up to 80°C) ensures versatility in applications like cold storage or hot liquid transport, without the risk of freeze damage or thermal expansion seen in steel.

Compared to conventional materials like stainless steel or PVC, UHMWPE food pipes offer superior abrasion resistance and a service life over three times longer, reducing replacement frequency and operational downtime. Their leak-free design addresses the high leakage rates (15-30% in PCCP or cast iron pipes), ensuring efficient and contamination-free food transport. The pipes’ eco-friendly design, requiring no rust-proofing or frequent maintenance, reduces operational costs by up to 95% compared to metal pipelines, making them a cost-effective and sustainable solution for food processing facilities.

These pipes are also used in pharmaceutical and cosmetic industries, where hygiene and chemical resistance are critical. Their smooth inner surface enhances flow efficiency by over 20% compared to steel pipes, saving energy in pumping operations. For inquiries or custom orders, contact Shandong Buoy and Pipe Industry Co., Ltd. at sales@buoyandpipe.com.